Steel surface corrosion-resistant composite titanium alloy coating and preparation method thereof

A titanium alloy and corrosion-resistant technology, which is applied in the field of corrosion-resistant composite titanium alloy coating on the surface of steel and its preparation, can solve the problems of weak interface performance, large difference in thermal and physical properties, and deterioration of coating performance, so as to improve the bonding strength and surface Titanium content, good corrosion protection, improving the effect of highly brittle interfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of corrosion-resistant composite titanium alloy coating on steel surface, its preparation method comprises the following steps:

[0033] 1) Surface roughening and cleaning of Q235 low carbon steel plate;

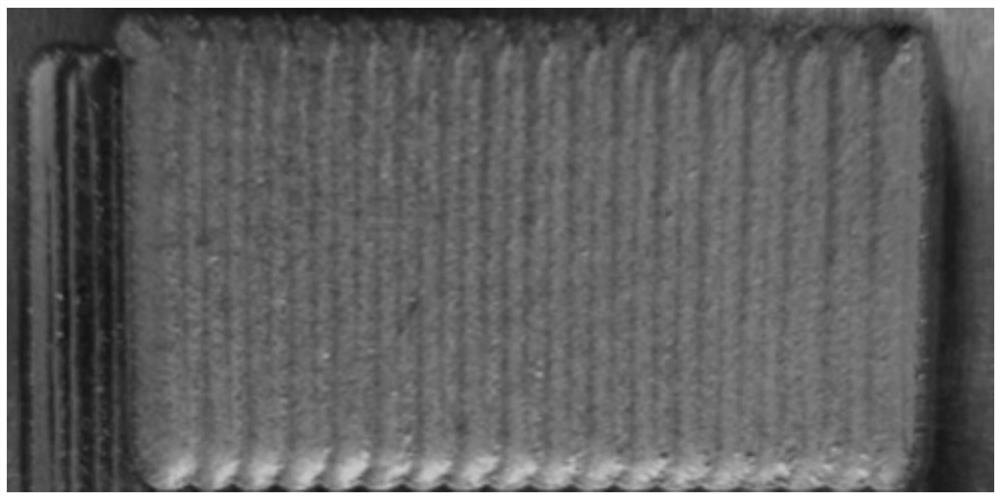

[0034] 2) Iron-based amorphous alloy powder Fe with a particle size of 50 μm to 200 μm 78 Si 9 B 13 (Atomic percentage) added to the laser cladding equipment, and then the iron-based amorphous powder Fe 78 Si 9 B 13 Cladding on the Q235 low-carbon steel plate treated in step 1), the cladding power is 1200W (for flat-top light with a laser spot diameter of 2.8mm), and the cladding overlap rate is 50%, forming an iron plate with a thickness of about 300 μm Based amorphous alloy coating (ie FeSiB transition layer);

[0035] 3) Put Ti6Al4V (grade: TC4) spherical powder with a particle size of 150 mesh to 300 mesh into the laser cladding equipment, and then cladding the Ti6Al4V spherical powder on the iron-based amorphous alloy coating formed in step 2), the c...

Embodiment 2

[0040] A kind of corrosion-resistant composite titanium alloy coating on steel surface, its preparation method comprises the following steps:

[0041] 1) Surface roughening and cleaning of Q235 low carbon steel plate;

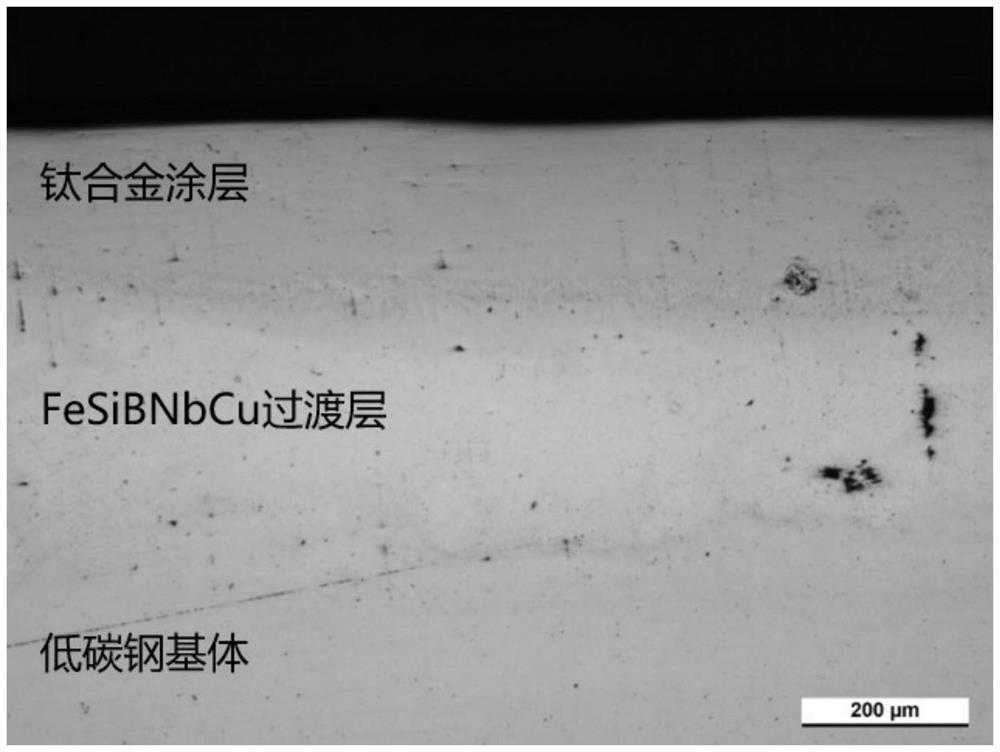

[0042] 2) Iron-based amorphous alloy powder Fe with a particle size of 50 μm to 200 μm 73.5 Si 13.5 B 9 Nb 3 Cu (atomic percentage) is added to the laser cladding equipment, and then the iron-based amorphous powder Fe 73.5 Si 13.5 B 9 Nb 3 Cu cladding is carried out on the Q235 low-carbon steel plate treated in step 1), the cladding power is 1000W (for flat-top light with a laser spot diameter of 2.8mm), the cladding overlap rate is 50%, and a thickness of about 300 μm is formed. Iron-based amorphous alloy coating (ie FeSiBNbCu transition layer);

[0043] 3) Add titanium powder with a particle size of 50 μm to 150 μm into the laser cladding equipment, and then cladding the titanium powder on the iron-based amorphous alloy coating formed in step 2), the ...

Embodiment 3

[0047] A kind of corrosion-resistant composite titanium alloy coating on steel surface, its preparation method comprises the following steps:

[0048] 1) Surface roughening and cleaning of Q235 low carbon steel plate;

[0049] 2) Iron-based amorphous alloy powder Fe with a particle size of 50 μm to 200 μm 73.5 Si 13.5 B 9 Nb 3Cu (atomic percentage) is added to the laser cladding equipment, and then the iron-based amorphous powder Fe 73.5 Si 13.5 B 9 Nb 3 Cu cladding is carried out on the Q235 low-carbon steel plate treated in step 1), the cladding power is 1000W (for flat-top light with a laser spot diameter of 2.8mm), the cladding overlap rate is 50%, and a thickness of about 400 μm is formed. Iron-based amorphous alloy coating (ie FeSiBNbCu transition layer);

[0050] 3) Add titanium powder with a particle size of 50 μm to 150 μm into the laser cladding equipment, and then clad the titanium powder on the iron-based amorphous alloy coating formed in step 2), with a cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com