Antibacterial odor-free impregnated paper and preparation method thereof

A technology of impregnating paper and deodorizing, which is applied in the field of impregnating paper, which can solve the problems of brittleness and easy cracking, and achieve the effect of improving strength, reducing content and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

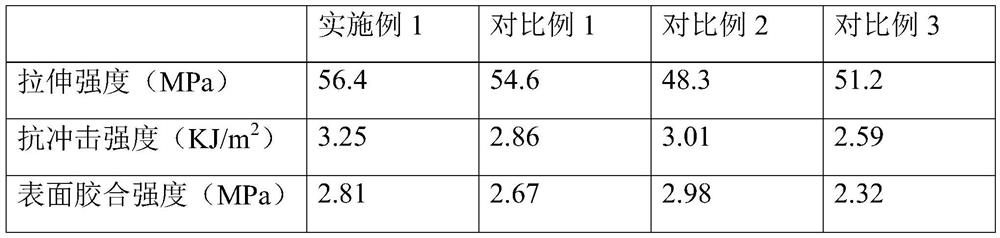

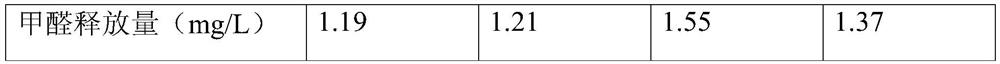

Examples

Embodiment 1

[0024] A preparation method for antibacterial and deodorant impregnated paper, comprising the steps of:

[0025] (1) Preparation of impregnation glue: add 6 weight parts of polyvinyl alcohol and 15 weight parts of activated carbon powder to the polyvinyl acetate emulsion of 30 weight parts and carry out ultrasonic mixing to obtain a modified liquid; Add an alkaline regulator to 37% formaldehyde aqueous solution, adjust the pH value to 9.0 and heat up to 45°C, then add 35 parts by weight of melamine and 45 parts by weight of urea, heat up to 95°C, keep warm for 40 minutes, then add an acidic regulator to adjust pH value to 6.0, heat preservation reaction for 15 minutes, add modified solution and stir evenly, heat preservation reaction for 35 minutes, add alkaline regulator, adjust pH value to 8.5, then add 20 parts by weight of melamine, continue heat preservation reaction for 60 minutes, cool down to 45°C, Add 6.5 parts by weight of urea, keep warm for 15 minutes, drop to norm...

Embodiment 2

[0035] A preparation method for antibacterial and deodorant impregnated paper, comprising the steps of:

[0036] (1) Preparation of impregnation glue: add 5 weight parts of polyvinyl alcohol and 10 weight parts of activated carbon powder to the polyvinyl acetate emulsion of 25 weight parts and carry out ultrasonic mixing to obtain modified liquid; Add an alkaline regulator to 35% formaldehyde aqueous solution, adjust the pH value to 8.5 and heat up to 40°C, then add 30 parts by weight of melamine and 40 parts by weight of urea, heat up to 90°C, keep warm for 30 minutes, then add an acidic regulator to adjust pH value to 5.5, heat preservation reaction for 10 minutes, add modified solution and stir evenly, heat preservation reaction for 30 minutes, add alkaline regulator, adjust pH value to 8.0, then add 15 parts by weight of melamine, continue heat preservation reaction for 50 minutes, cool down to 40°C, Add 5 parts by weight of urea, keep warm for 10 minutes, drop to normal t...

Embodiment 3

[0046] A preparation method for antibacterial and deodorant impregnated paper, comprising the steps of:

[0047] (1) Preparation of impregnation glue: add polyvinyl alcohol of 7 weight parts and the active carbon powder of 20 weight parts in the polyvinyl acetate emulsion of 35 weight parts and carry out ultrasonic mixing, make modified liquid; Add an alkaline regulator to 40% formaldehyde solution, adjust the pH value to 9.5 and heat up to 50°C, then add 40 parts by weight of melamine and 50 parts by weight of urea, heat up to 95°C, keep warm for 50 minutes, then add an acidic regulator to adjust pH value to 6.0, heat preservation reaction for 20 minutes, add modified solution and stir evenly, heat preservation reaction for 40 minutes, add alkaline regulator, adjust pH value to 9.0, then add 25 parts by weight of melamine, continue heat preservation reaction for 60 minutes, cool down to 50°C, Add 8 parts by weight of urea, keep warm for 20 minutes, drop to normal temperature,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com