Rotary kiln low-nitrogen combustion device and production method

A low-nitrogen combustion and low-nitrogen burner technology, applied in rotary drum furnaces, waste heat treatment, furnaces, etc., can solve the problems of low-nitrogen combustion in rotary kilns not reaching the ideal target, single low-nitrogen combustion, etc. The effect of reducing emissions, increasing CO2 concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

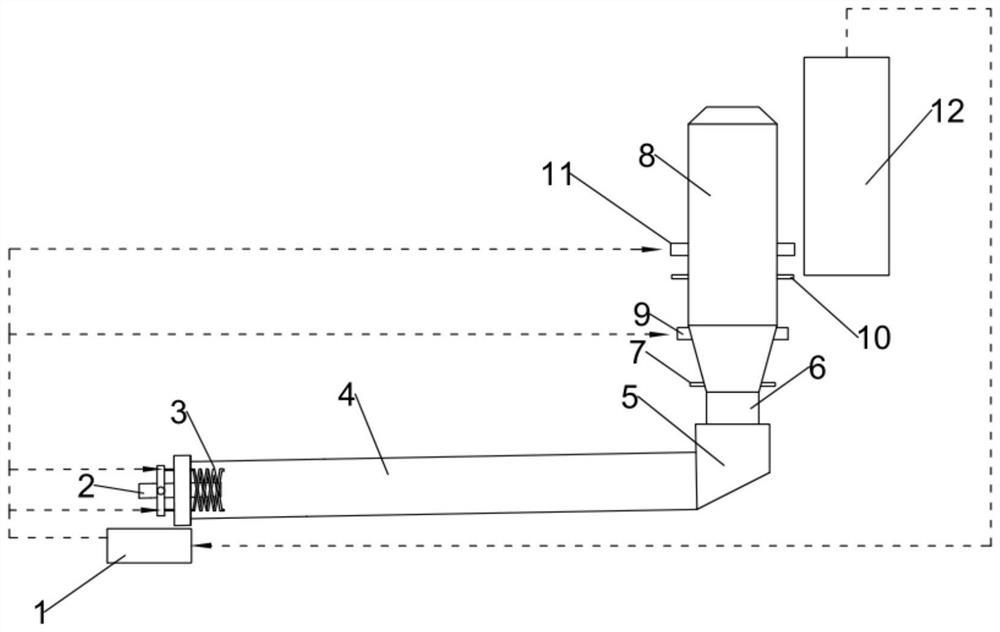

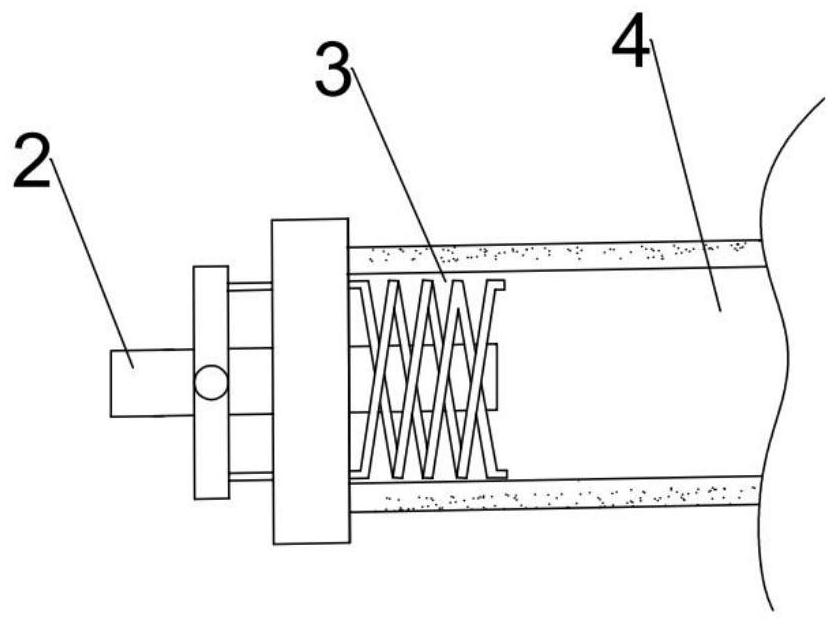

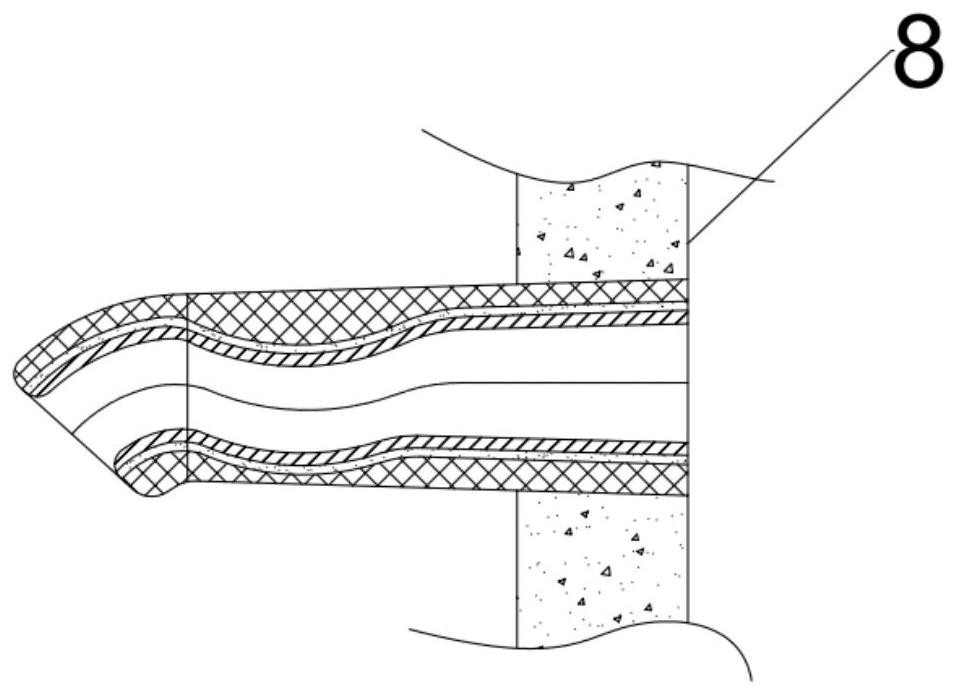

[0040] The present invention proposes a rotary kiln low-nitrogen combustion device for the first time, as shown in Figure 1-3, including a cooler 1, a low-nitrogen burner 2, a secondary air pipe 3, a rotary kiln 4, a decomposition furnace 8 and a preheater 12 . The angle between the rotary kiln 4 and the horizontal plane is 1-3°. Both the low-nitrogen burner 2 and the cooler 1 are arranged at the kiln head of the rotary kiln 4 , and the kiln tail smoke chamber 5 is provided at the kiln tail of the rotary kiln 4 . The calciner 8 includes a conical lower furnace body and an upper furnace body, and the kiln tail smoke chamber 5 is connected to the lower furnace body of the calciner 8 through an ascending flue 6 . The lower part of the lower furnace body of the calciner 8 is provided with two lower coal feeding devices 7, and the upper part is provided with two lower tertiary air ducts 9, and the two lower coal feeding devices are symmetrically distributed on both sides of the ca...

Embodiment 2

[0047] This embodiment proposes a production method based on a rotary kiln low-nitrogen combustion device, the method adopts the rotary kiln low-nitrogen combustion device recorded in the present invention, and includes the following steps:

[0048] S1: Coal powder and primary air are sprayed into the rotary kiln through the low-nitrogen burner, and the high-temperature flue gas in the rotary kiln enters the preheater through the kiln tail flue chamber, ascending flue and calciner in sequence from the kiln tail. The lower primary air volume enables pulverized coal to achieve low-oxygen combustion and inhibits the formation of NOx.

[0049] S2: Pulverized coal is fed from the upper coal feeding device and the lower coal feeding device, and the amount of pulverized coal fed into the lower coal feeding device accounts for 10%-30% of the total amount of pulverized coal fed into the lower coal feeding device and the upper coal feeding device %. The raw meal is fed into the calcine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com