In-situ infrared ATR testing method of thermal color phase change thin film material

An in-situ infrared and testing method technology, applied in the investigation stage/state change, etc., can solve the problem of better real-time monitoring of the phase change process of samples without thermochromic thin films, and achieve the advantages of simple operation, integrity maintenance, and avoidance of impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

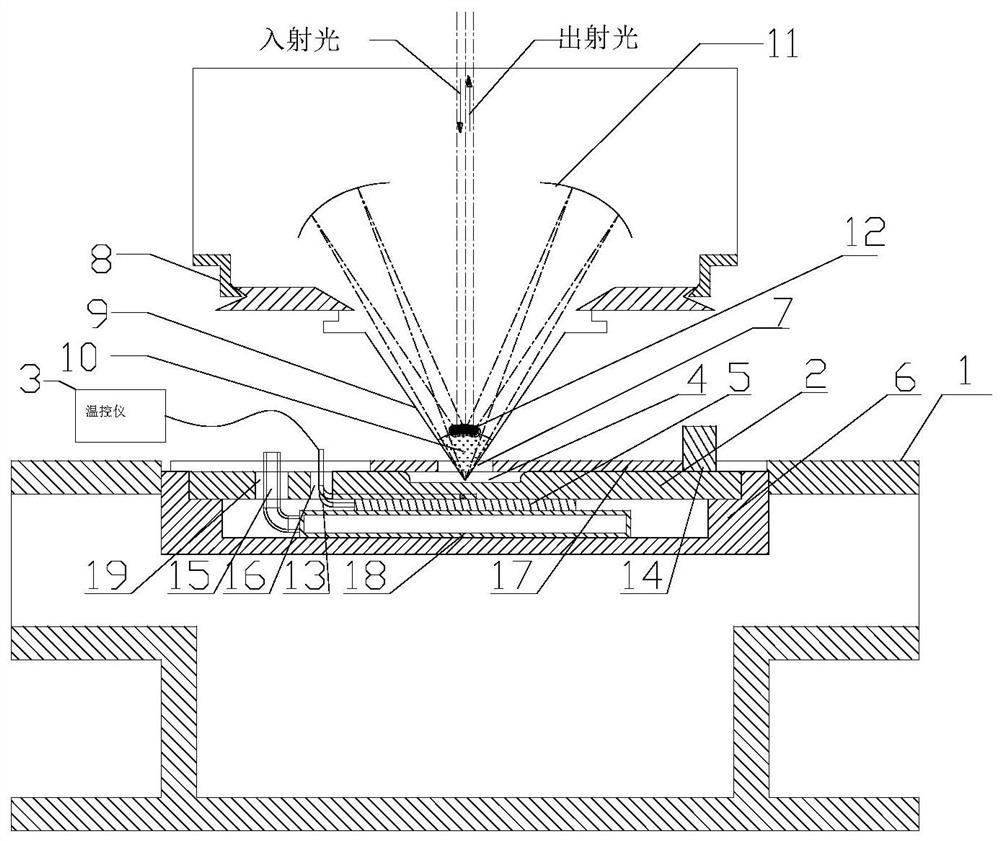

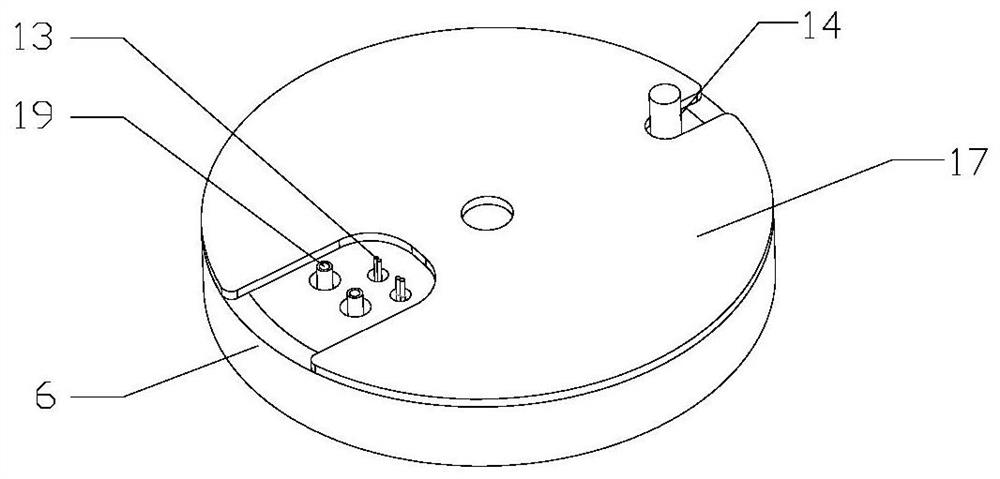

[0042] like Figure 1-4As shown, the thermochromic phase-change thin film sample is placed in parallel in the sample groove 4 of the sample stage 2 for program temperature control, so that the objective crystal 10 of the infrared ATR objective lens 9 is in effective contact with the thin film sample, and it is tested under different temperature conditions. Attenuated total reflection infrared test.

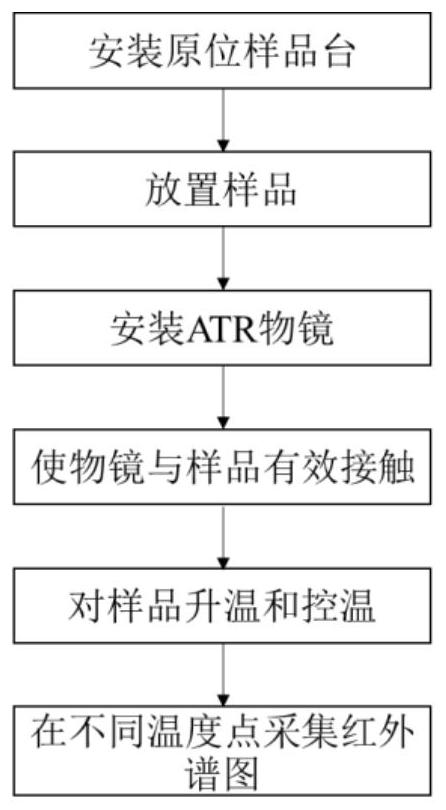

[0043] A kind of in-situ infrared ATR testing method of thermochromic phase change film material, specifically comprises the following steps:

[0044] S1: the in-situ sample stage is installed on the loading platform 1, and the in-situ sample stage is locked through the rotation and positioning of the fastener 14;

[0045] S2: For the thin film sample, the base of the sample faces downward, and the side with the thin film faces upward and is placed in parallel in the sample groove 4;

[0046] S3: Lower the loading platform 1 to a proper position, insert the ATR objective lens 9 ...

experiment example 1

[0058] like Image 6 As shown, the in-situ infrared ATR testing method of the thermochromic phase-change film material of Example 1 is used to test the glass substrate alum oxide composite film, and the thickness of the alum oxide composite film is 80nm. Locking; put the sample with the side of the alum oxide composite film up into the sample slot of the in-situ sample stage; lower the object platform to a suitable position, insert the ATR objective lens into the wedge-shaped slot of the objective lens and push it to the test position; drop The ATR objective lens makes the objective lens crystal contact with the film effectively, and the induction pressure value is preferably 20; the heating rate of the rapid temperature change module is set to 5°C / S, and the spectrum test of the alum oxide composite film is carried out under the heating condition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com