Combined method for removing trace nitrogen

A micro-removal technology, applied in the field of denitrification, can solve the problems of processing technology influence, stable column bottom oil nitrogen content exceeding the standard, and inability to remove through physical separation or distillation, so as to increase energy consumption, increase emissions, and improve enterprise efficiency. benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

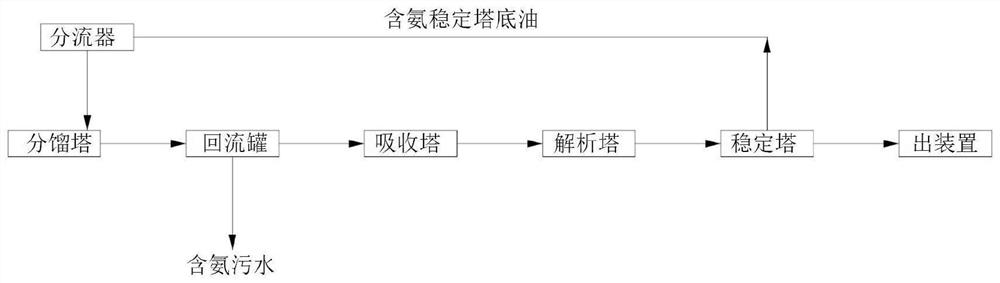

[0014] like figure 1 The shown combined method of removing trace nitrogen of the present invention is used to remove the residual amine liquid in the gasoline produced, and the oil gas enters the absorption stabilization system after being divided by the fractionation system. The absorption stabilization system includes an absorption tower, a desorption tower, Absorption tower, stabilization tower and corresponding cold exchange equipment.

[0015] The bottom of the fractionation tower of the present invention is provided with a steam injection system for injecting steam, and the top of the fractionation tower is provided with a splitter. The oil outlet of the stabilizing tower is provided with two connecting lines, the first connecting line exits the device and outputs stable gasoline, and the first connecting line is provided with an online analyzer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com