Anti-cracking recycled concrete and preparation method thereof

A technology for recycled concrete and anti-cracking, applied in the field of concrete, can solve problems such as poor crack resistance, and achieve the effects of improving mechanical properties, crack resistance, compressive strength, and crack resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

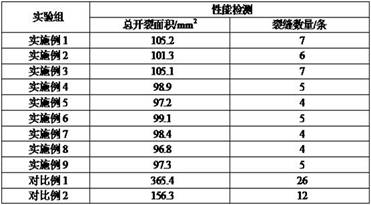

Examples

preparation example 1

[0041] (1) Take 2 kg of aluminum nitrate solution and 0.1 kg of aluminum isopropoxide particles, stir and mix, grind and disperse, collect the dispersed slurry and stir and hydrolyze to obtain aluminum source hydrolyzate;

[0042] (2) Mix 3kg tetraethyl orthosilicate with 10kg water, adjust the pH to 6.0 with glacial acetic acid, stir and hydrolyze to obtain silicon source hydrolyzate;

[0043] (3) Mix 1 kg of silicon source hydrolyzate with 2 kg of aluminum source hydrolyzate and place it at 60°C for heat preservation polycondensation reaction, use glacial acetic acid to adjust the pH to 2.5, heat heat and stir for entanglement treatment, let it stand and cool to room temperature, and the obtained product can be prepared Si-alumina composite sol 1.

preparation example 2

[0045] (1) Take 3 kg of aluminum nitrate solution and 0.2 kg of aluminum isopropoxide particles, stir and mix, grind and disperse, collect the dispersed slurry and stir and hydrolyze to obtain aluminum source hydrolyzate;

[0046] (2) Mix 4kg tetraethyl orthosilicate with 12kg water, adjust the pH to 6.0 with glacial acetic acid, stir and hydrolyze to obtain silicon source hydrolyzate;

[0047] (3) Mix 1 kg of silicon source hydrolyzate with 2 kg of aluminum source hydrolyzate and place it at 70°C for heat preservation polycondensation reaction, use glacial acetic acid to adjust the pH to 2.7, heat heat and stir for entanglement treatment, let it stand and cool to room temperature, and the obtained product can be prepared Si-alumina composite sol 2.

preparation example 3

[0049] (1) Take 3 kg of aluminum nitrate solution and 0.2 kg of aluminum isopropoxide particles, stir and mix, grind and disperse, collect the dispersed slurry and stir and hydrolyze to obtain aluminum source hydrolyzate;

[0050] (2) Mix 5kg tetraethyl orthosilicate with 15kg water, adjust the pH to 6.0 with glacial acetic acid, stir and hydrolyze to obtain silicon source hydrolyzate;

[0051] (3) Mix 1 kg of silicon source hydrolyzate with 3 kg of aluminum source hydrolyzate and place it at 80°C for heat preservation polycondensation reaction, use glacial acetic acid to adjust the pH to 3.0, heat heat and stir for entanglement treatment, let it stand and cool to room temperature, and the obtained product can be prepared Si-alumina composite sol 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com