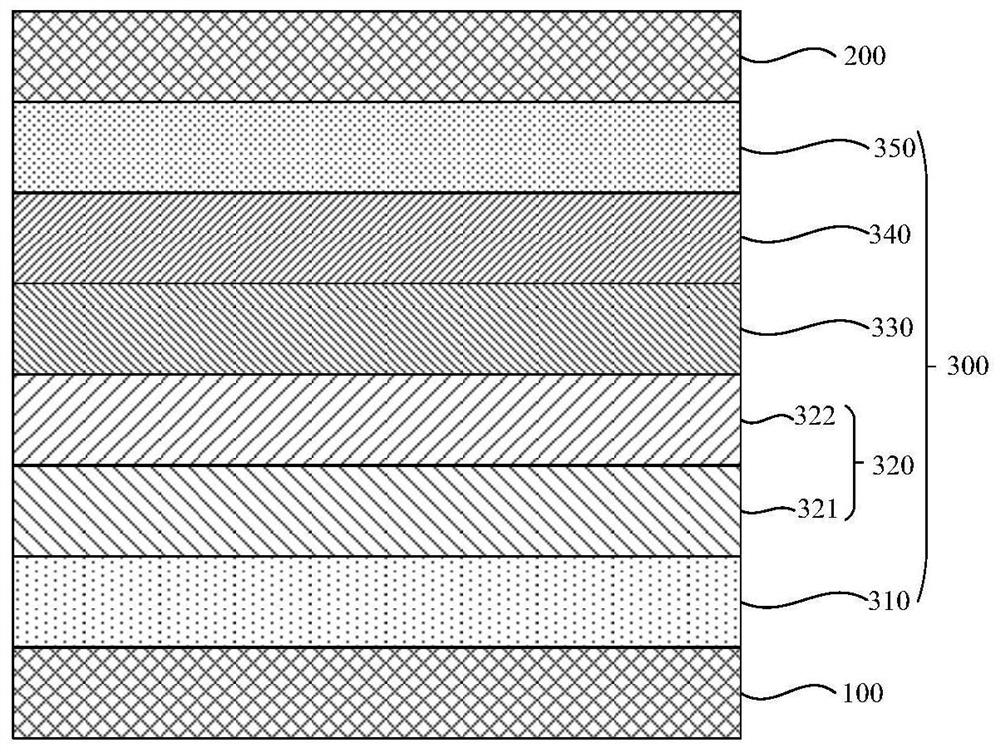

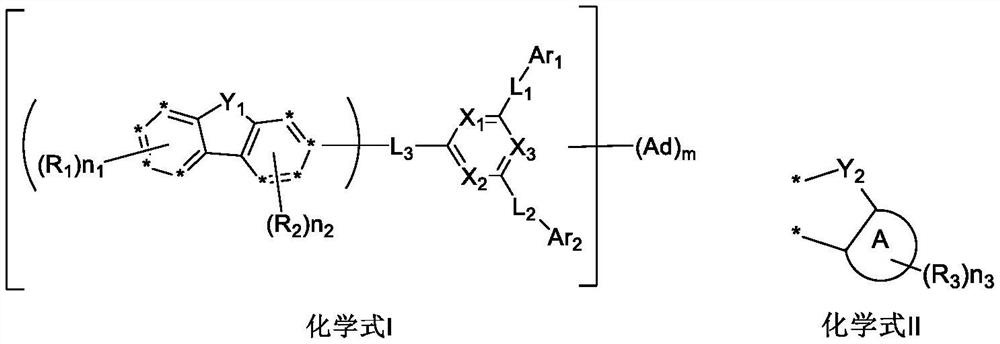

Organic compound, and electronic element and electronic device using same

An organic compound and fusion technology, which is applied in electrical components, organic chemistry, and electric solid-state devices, can solve the problems of undeveloped organic layer materials and achieve the goal of improving exciton utilization, increasing current efficiency, and prolonging device life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0175] Preparation Example 1 Preparation of Compound 1

[0176] 1) Synthesis of intermediate IM 1-1

[0177]

[0178] Add 1-adamantanol (50.0g, 328.4mmol), bromobenzene (51.6g, 328.4mmol), dichloromethane (DCM, 500mL) into a round-bottomed flask, and cool down to -5~0°C under nitrogen protection. Add trifluoromethanesulfonic acid (73.9g, 492.6mmol) dropwise at -5~0°C, keep stirring for 3h; add deionized water (300mL) to the reaction solution and wash until pH=7, add dichloromethane (100mL) to carry out Extract, combine organic phase, use anhydrous magnesium sulfate to carry out drying, filter, remove solvent under reduced pressure; Gained crude product uses n-heptane as mobile phase to carry out silica gel column chromatography purification, obtains white solid intermediate IM 1-1 (52.6g, collects rate 55%).

[0179] Intermediate IM 1-2 to IM 1-3 were prepared in the same manner as Intermediate IM 1-1, except that raw material A in Table 1 was used instead of the raw mate...

preparation example 2-6

[0189] The following compound was prepared by the same synthetic method as Preparation Example 1, except that the raw material B in Table 2 was used instead of 2-bromo-4,6-diphenyl-[1,3,5]tri Oxyzine, intermediate C was used instead of intermediate IM1-1 in Preparation 1. The main raw materials used, the synthesized compounds and their yields and mass spectrometry results are shown in Table 2.

[0190] Table 2

[0191]

[0192] NMR data of compound 11:

[0193] 1 H-NMR (400MHZ, CD 2 Cl 2 ):9.25(s,1H),8.95(s,1H),8.53-8.51(m,2H),8.30(d,1H),8.11(d,1H),7.98(d,1H),7.95(s, 1H),7.72(d,1H),7.64-7.50(m,13H),7.45-7.40(m,4H),7.35-7.28(m,6H),2.20(s,3H),1.96(s,6H) ,1.84-1.74(m,6H).

preparation example 7

[0194] Preparation of Preparation Example 7 Compound 28

[0195]

[0196] Compound 28 was prepared according to the synthesis method of Preparation Example 1, except that the raw material indolo[2,3-A]carbazole (20g, 78.03mmol) was used instead of 5,7-dihydro-indolo[ 2,3-B]carbazole to obtain compound 28 (14.4g, yield 51%), m / z=698.32[M+H] + .

[0197] 1 H-NMR (400MHZ, CD 2 Cl 2 ):8.93(d,1H),8.67-8.58(m,5H),8.13(d,1H),8.09(d,1H),7.95(d,1H),7.71(d,2H),7.58(m, 6H),7.49(m,2H),7.34(m,3H),7.15(d,2H),2.19(s,3H),1.97(s,6H),1.81-1.75(m,6H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com