Preparation method of biodegradable PDT/Fe3O4 composite material

A composite material and biological technology, applied in the field of medical composite materials and its preparation, can solve the problems of biological rejection, poor image sensitivity, biological inertia, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0085] Typically, the preparation method of the present invention includes the steps of:

[0086] (S1) Mix the tetraned iron nanoparticles, biodegradable and biocompatible polymers, and the first solvent to form a first mixture, wherein the biodegradable and biocompatible polymers are in the first solvent. It is soluble;

[0087] (S2) Add a second solvent to the first mixture, thereby forming a complex of the tetrasoxide nanoparticles and biodegradable and biocompatible polymers; and

[0088] (S3) The precipitate was separated and dried to obtain a composite according to claim 1.

[0089] Preferably, the composite material of the present invention is PDT / Fe 3 O 4 Composite.

[0090] In a preferred example, the present invention provides a preparation of PDT / Fe 3 O 4 The method of the composite material includes the following steps:

[0091] (1) Synthesis of PDT

[0092] S1.1, the ratio of the monomer extrapolatomy amylide (DLLA) and the tri methylene carbonate (TMC) material i...

Embodiment 1

[0127] Example 1. Different matching PDT preparation

[0128] 1.1. Method

[0129] In the present embodiment, a polymer having a mixing ratio of a mixed proportion of extracted amphorodoxide (DLLA) and trikarcarbonate (TMC) was prepared, and compared properties. Methods as below:

[0130] (a) Take a certain amount of monomer-free lease (DLLA) and TMC (TMC), the ratio of the substances of both is 100: 0, 98: 2, 95: 5, 90 : 10,85: 15,80: 20,70: 30 and 0: 100;

[0131] (b) Select catalyst octoctanate Sn (OCT) 2 The ratio of the total mass of the monomer is 1.25: 1000;

[0132] (c) After the vacuum was 4 h, it was raised to 120 in an argon atmosphere, and the reaction was 6 h;

[0133] (d) The above product was dissolved by dichloromethane and anhydrous ether 2 to 3 times, and the PDT sample was evaporated in vacuo to 150 ° C.

[0134] (e) The above product was stored in a refrigerator of -20 ° C with an aluminum foil.

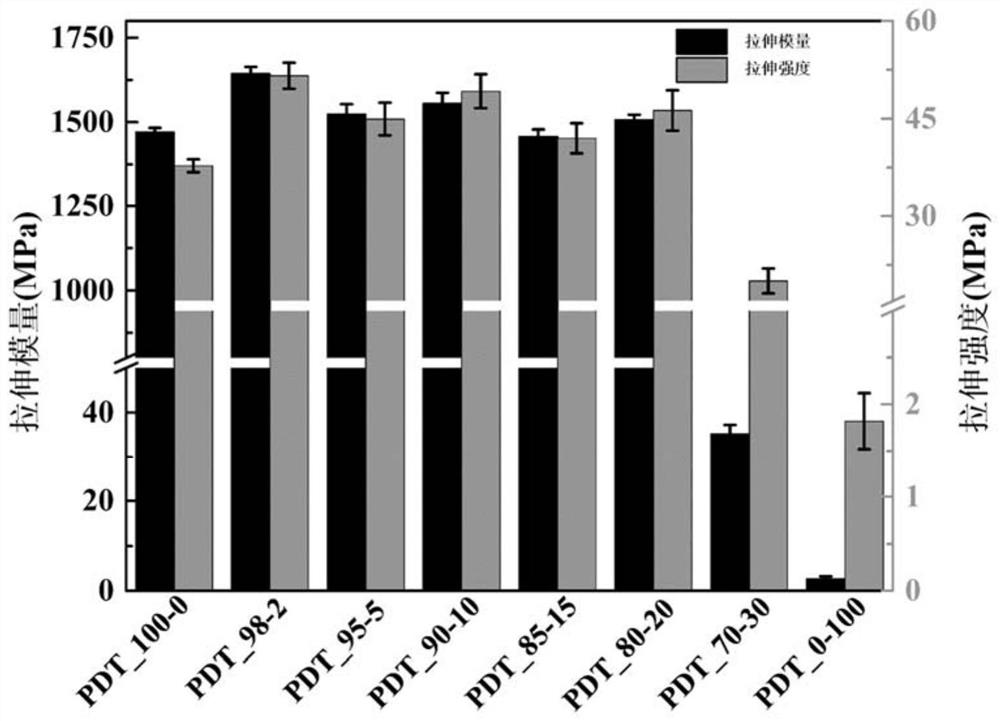

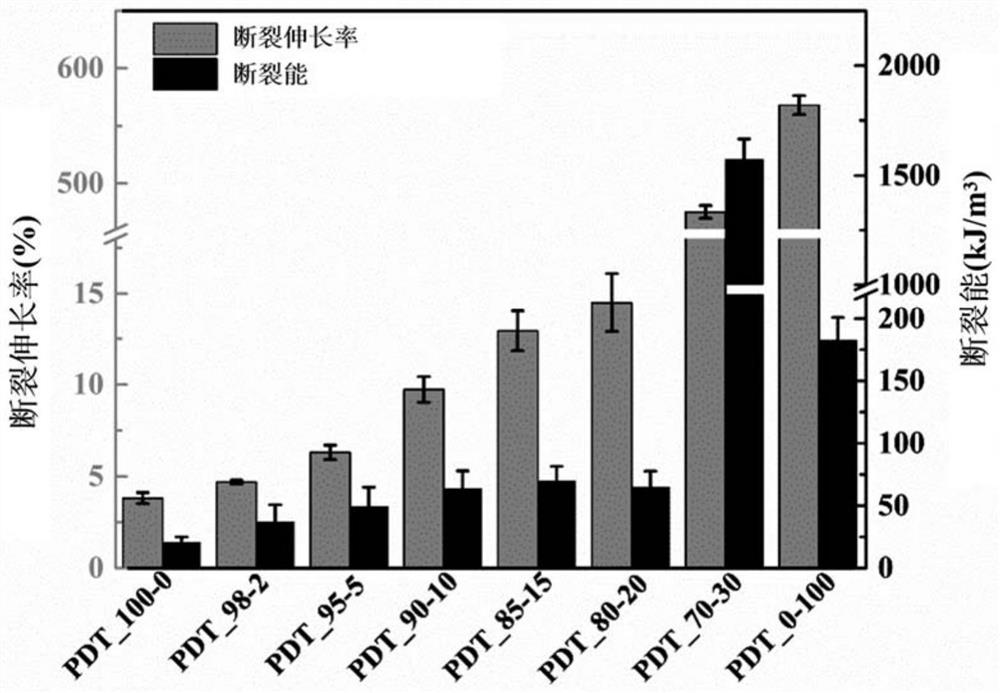

[0135] Such as Figure 1-2 As shown, the results show that the co...

Embodiment 2

[0139] Example 2. PDT material 3D printing

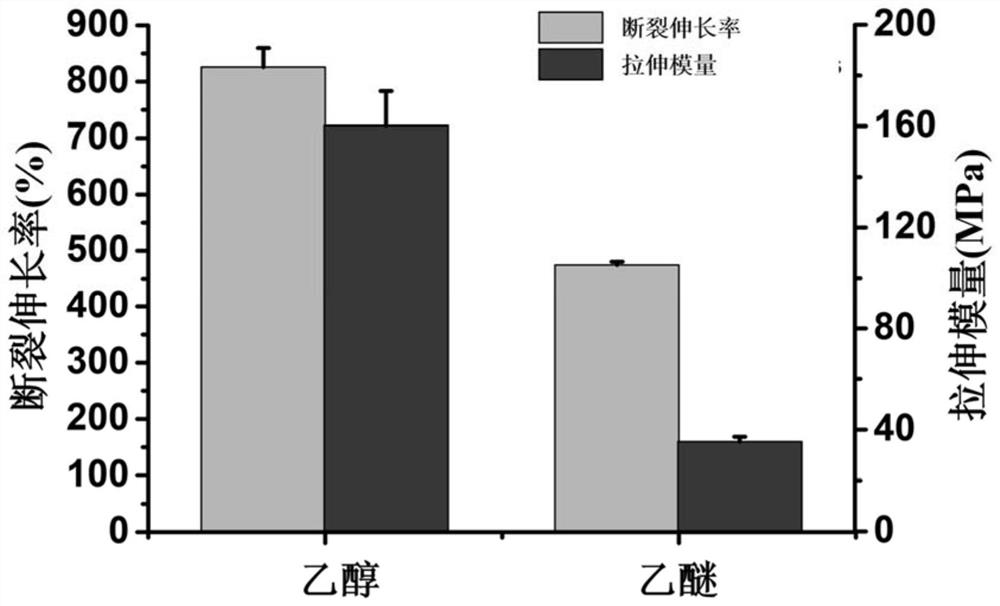

[0140] Example 1 was repeated, and the ratio of the substance of the monomer extracted amphorodoxide (DLLA) and a trimethylene carbonate (TMC) was 70:30, and anhydrous in step (d) Ethanol is replaced by waterless diethyl ether. After 3D printing, Figure 4 The product shown. Depend on Figure 4 It can be seen that the PDT material has the properties of the printed molding in the form of the substance of the monomer extracted amphorodoxide (DLLA) and trikylene carbonate (TMC). Properties of 70:30.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile modulus | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com