Formaldehyde-free soybean protein adhesive and preparation method thereof

A soybean protein and adhesive technology, which is applied in the preparation of protein adhesives, animal glue or gelatin, and adhesives, etc., can solve the problems of free formaldehyde emission, poor water-resistant bonding performance, and large protein molecular weight of wood-based panels. To achieve the effect of favorable stability, good water-resistant bonding performance and high product reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

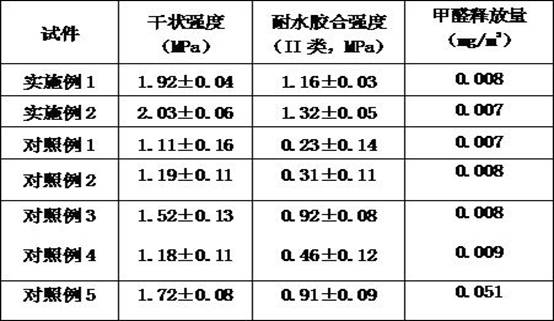

Examples

Embodiment 1

[0027] The present embodiment provides an aldehyde-free soybean protein adhesive, and the adhesive is prepared according to the following weight ratios:

[0028] Soy flour 32kg

[0029] Dispersion medium 68kg

[0030] Crosslinker 3kg

[0031] Enhancer 0.3kg

[0032] This embodiment also provides a method for preparing the above-mentioned adhesive, and the specific preparation steps of the above-mentioned adhesive are as described in the content of the invention above.

Embodiment 2

[0034] The present embodiment provides an aldehyde-free soybean protein adhesive, and the adhesive is prepared according to the following weight ratios:

[0035] Soy flour 32kg

[0036] Dispersion medium 68kg

[0037] Crosslinker 5kg

[0038] Enhancer 0.6kg

[0039] This embodiment also provides the preparation method of the above-mentioned adhesive, and the preparation method of the adhesive described in this embodiment is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com