Method for preparing N-(2-aminoethyl)-3-aminopropyltrimethoxysilane by adopting pipeline reactor

A technology of aminopropyltrimethoxysilane and chloropropyltrimethoxysilane is applied in the field of continuous preparation of aminopropyltriethoxysilane by using pipeline reactors, which can solve the problems of inconvenient starting and parking, complicated equipment and stable problems such as poor performance, to achieve the effects of low labor cost, shortened response time, and small liquid holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

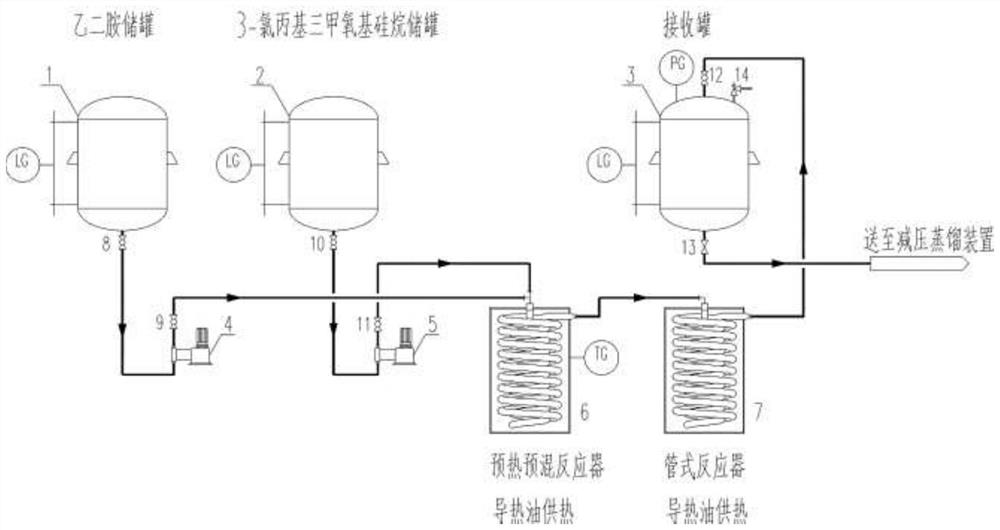

[0023] Device example: a continuous pipeline device for the preparation of N-(2-aminoethyl)-3-aminopropyltrimethoxysilane, its structure is as follows figure 1 Shown, including tubular reactor 7 and other equipment.

[0024] The ethylenediamine storage tank 1 is connected to the inlet of the preheating premix reactor 6 through a metering pump 4 through a pipeline, and the 3-chloropropyltrimethoxysilane storage tank 2 is connected to the preheating premix reactor 6 after the metering pump 5 The inlet is connected, the outlet of the preheating and premixing reactor 6 is connected with the inlet of the tubular reactor 7, the outlet of the tubular reactor 7 is connected with the inlet of the receiving tank 3, and a valve 13 is arranged at the outlet of the receiving tank 3; the reaction liquid passes through The outlet of the receiving tank 3 is sent to a vacuum distillation unit to obtain a refined product through distillation.

[0025] A valve 8 is provided on the pipeline betw...

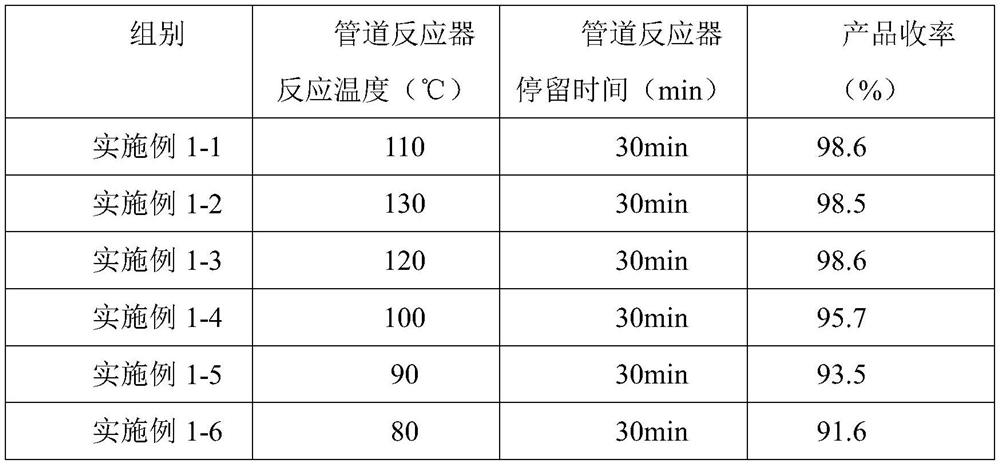

Embodiment 1-1

[0030] Embodiment 1-1: A preparation method of N-(2-aminoethyl)-3-aminopropyltrimethoxysilane, comprising the following steps:

[0031] The ethylenediamine in the ethylenediamine storage tank 1 is pumped into the preheating premix reactor 6 with a flow rate of 7.5mL / min through the feed pump 4, and the 3-chloropropyltrimethoxysilane in the 3-chloropropyltrimethoxysilane storage tank 3 Propyltrimethoxysilane is pumped into the preheating premixing reactor 6 at a flow rate of 5.1 mL / min through the feed pump 5. The size of the preheating premixing reactor 6 is fixed, with a diameter of 6 mm and a length of 10 m. The preheating temperature It is generally set at 80-90°C; after preheating and mixing, the mixed solution enters the pipeline reactor 7, the diameter of the pipeline reactor 7 is 6mm, and its length is based on the set reaction time (that is, the raw material mixed solution in the pipeline reactor 7) is adjusted, and the reaction residence time of the raw material mixtu...

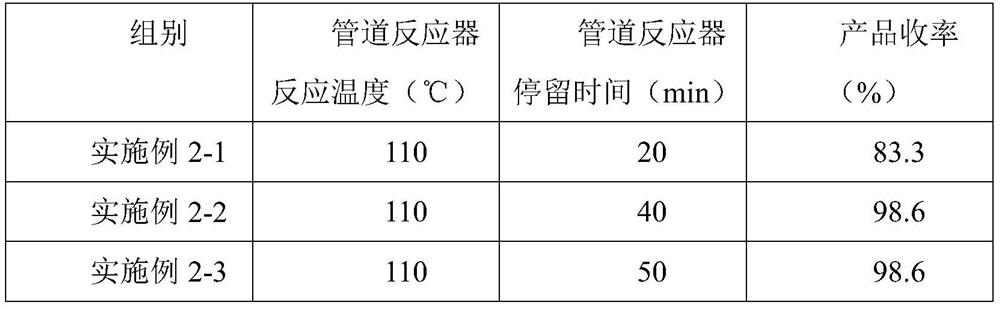

Embodiment 2-1~ Embodiment 2-3

[0037] Compared with Example 1-1, the tube length of the tube reactor 7 is changed, thereby changing the reaction residence time of the raw material mixed liquid in the tube reactor 7, and the rest is the same as that of Example 1-1. The product yield was detected to obtain the following data (Table 2).

[0038] Table 2, the impact of reaction residence time on N-(2-aminoethyl)-3-aminopropyltrimethoxysilane productive rate

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com