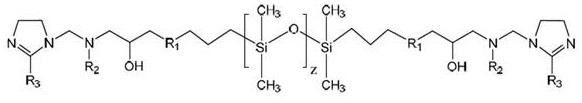

Low-yellowing hydrophilic block polyether amino silicone oil and preparation method thereof

A hydrophilic block, polyether amino technology, applied in fiber processing, textiles and papermaking, improved hand fibers, etc., can solve problems such as reducing softness, improve softness, avoid softness decline, and improve yellowing. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

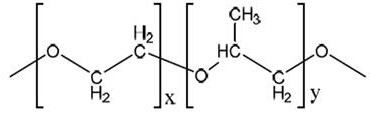

[0026] Add 100 g parts of polyether-terminated epoxy silicone oil (x=10, y=0, z=30) and 6.61 parts of diethylenetriamine (64 mmol) into a four-necked flask equipped with a thermometer and a reflux condenser, without adding Solvent A, stir and react at 60°C for 3 hours, then add 5.47 parts of stearic acid (19mmol), heat up to 120°C, carry out vacuum dehydration until no water comes out, cool down to room temperature 25°C, add diethylene glycol monobutyl ether 10 parts and 16.18 parts (128 mmol) of dimethyl sulfate, and stirred to obtain a low-yellowing hydrophilic block polyether amino silicone oil.

Embodiment 2

[0028] Add 100 g parts of polyether-terminated epoxy silicone oil (x=25, y=25, z=108) and 1.41 parts of diethylenetriamine (14 mmol) into a four-necked flask equipped with a thermometer and a reflux condenser, and stir Under the conditions, add 10 parts of solvent ethylene glycol monobutyl ether, stir and react at 80 ° C for 6 hours, then add 2.19 parts (11 mmol) of lauric acid, raise the temperature to 180 ° C, carry out vacuum dehydration until no moisture comes out, and cool down to room temperature 60 ℃, add 20 parts of ethylene glycol butyl ether and 2.58 parts (21 mmol) of dimethyl sulfate, and stir to obtain a low-yellowing hydrophilic block polyether amino silicone oil.

Embodiment 3

[0030] Add 100 g parts of polyether-terminated epoxy silicone oil (x=13, y=6, z=135) and 1.38 parts of diethylenetriamine (13 mmol) into a four-necked flask equipped with a thermometer and a reflux condenser, and stir Under the conditions, add 10 parts of solvent ethylene glycol phenyl ether, stir and react at 80 ° C for 8 hours, then add 0.77 parts (11 mmol) of butyrolactone, raise the temperature to 180 ° C, carry out vacuum dehydration until no moisture comes out, and cool down to room temperature 60 ℃, add 20 parts of ethylene glycol butyl ether and 2.53 parts of dimethyl sulfate (20 mmol), and stir to obtain a low-yellowing hydrophilic block polyether amino silicone oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com