Boron-sulfur co-doped spongy porous carbon, preparation method thereof, carbon electrode and zinc ion hybrid capacitor

A co-doping and sponge-like technology, applied in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, carbon compounds, etc., can solve the problems of complex preparation process and the electrochemical performance of zinc-ion hybrid capacitors to be improved, and achieve the goal of preparation Simple method, excellent cycle stability, and the effect of increasing specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of preparation of carbon electrode, comprises the following steps:

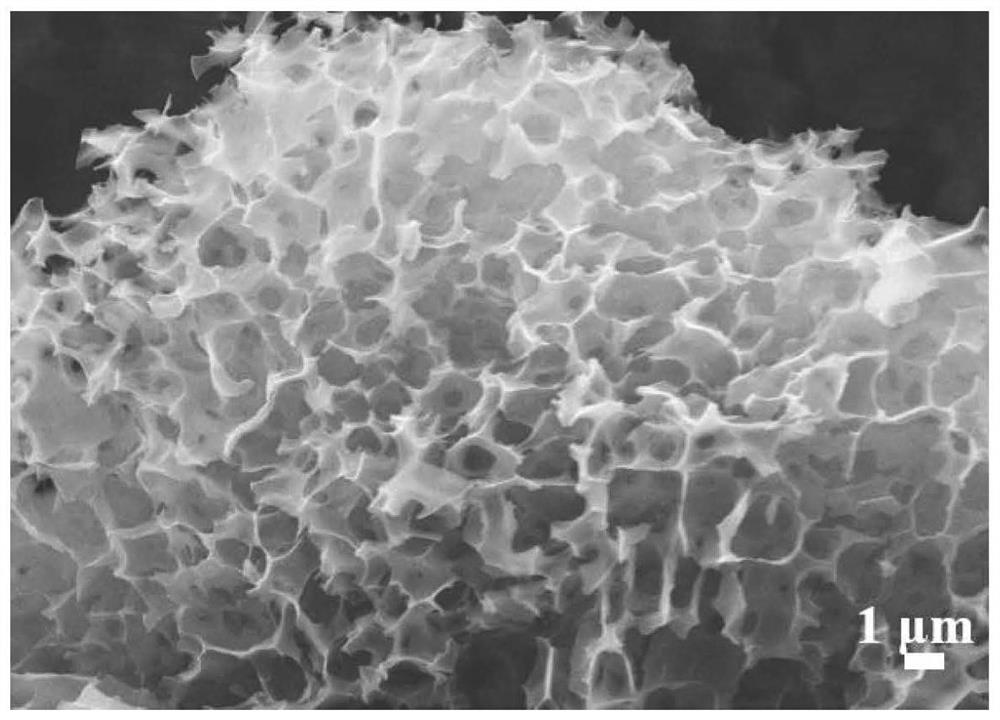

[0037] S1: Bamboo chips were used as carbon source material, sonicated in absolute ethanol solution and deionized water for 2 hours, and then dried in an oven at 60°C for 4 hours;

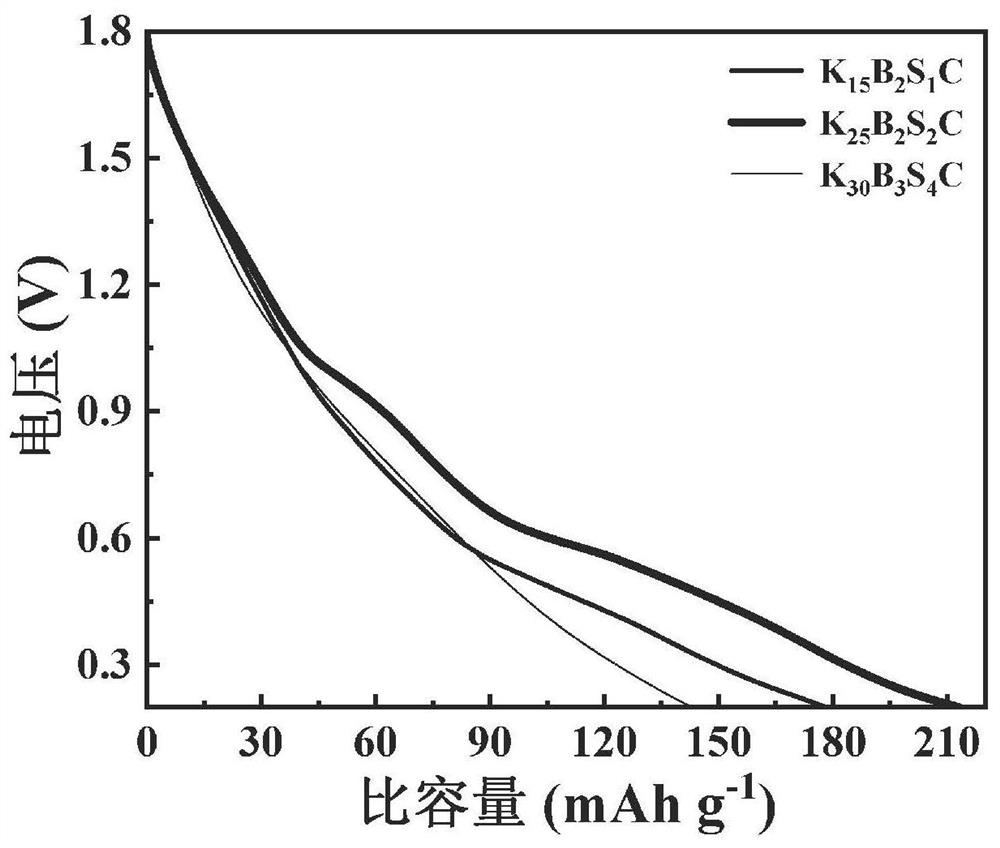

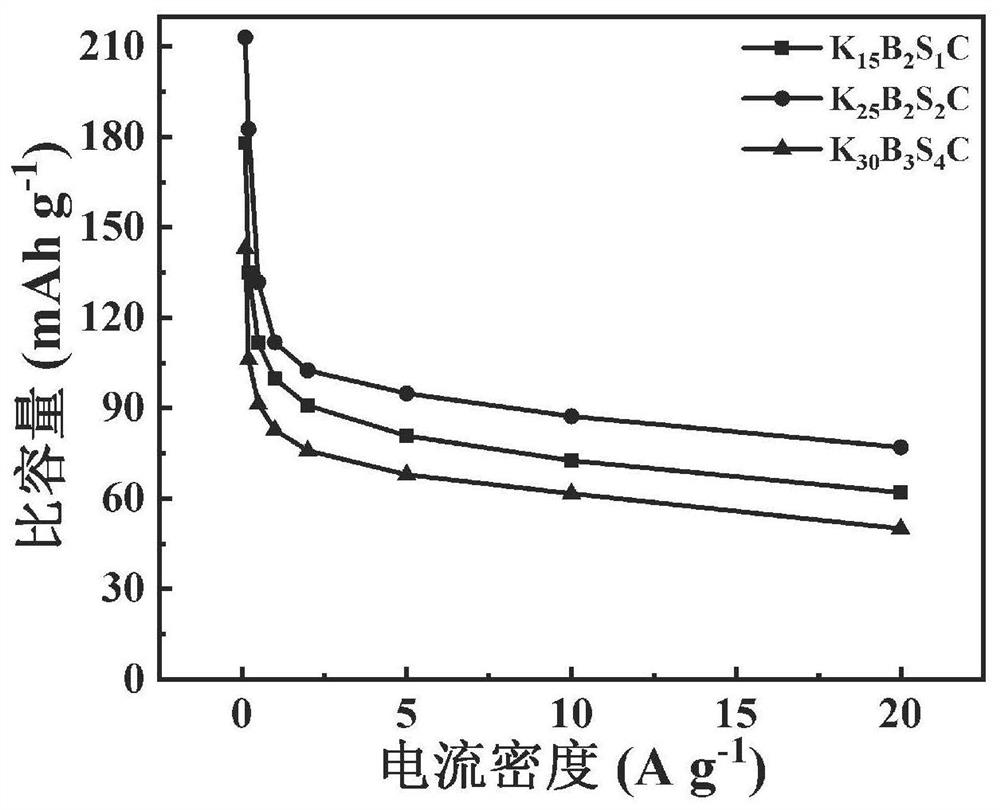

[0038] S2: Put the dried bamboo chips into an agate mortar and grind them fully, then mix them with potassium carbonate, potassium tetraborate and potassium thioacetate, the mass ratio is bamboo chips: potassium carbonate: potassium tetraborate: potassium thioacetate = 5:15:2:1, carbonization and activation in Ar atmosphere for 1h, then naturally cool the sample to room temperature;

[0039] S3: The sample in S2 was magnetically stirred for 8 hours, then suction-filtered twice in absolute ethanol solution, then five times in deionized water, and finally dried for 4 hours to obtain the boron-sulfur co-doped spongy porous carbon, denoted as K 15 B 2 S 1 c.

[0040] S4, the obtained 30mg K 15 B 2 S 1 C. Add 5 mg...

Embodiment 2

[0045] A kind of preparation of carbon electrode, comprises the following steps:

[0046] S1: Bamboo chips were used as carbon source material, sonicated in absolute ethanol solution and deionized water for 2 hours, and then dried in an oven at 60°C for 4 hours;

[0047] S2: Put the dried bamboo chips into an agate mortar and grind them fully, then mix them with potassium carbonate, potassium tetraborate and potassium thioacetate, the mass ratio is bamboo chips: potassium carbonate: potassium tetraborate: potassium thioacetate = 5:25:2:2, carbonization and activation in Ar atmosphere for 2h, then naturally cool the sample to room temperature;

[0048] S3: The sample in S2 was magnetically stirred for 10 hours, then suction-filtered in absolute ethanol solution for 3 times, then in deionized water for 6 times, and finally dried for 5 hours to obtain the boron-sulfur co-doped spongy porous carbon, denoted as K 25 B 2 S 2 c.

[0049] S4, the obtained 40mg K 25 B 2 S 2 C. ...

Embodiment 3

[0054] A kind of preparation of carbon electrode, comprises the following steps:

[0055] S1: Bamboo chips were used as carbon source material, ultrasonicated in absolute ethanol solution and deionized water for 3 hours, and then dried in an oven at 60°C for 4 hours;

[0056] S2: Put the dried bamboo chips into an agate mortar and grind them fully, then mix them with potassium carbonate, potassium tetraborate and potassium thioacetate, the mass ratio is bamboo chips: potassium carbonate: potassium tetraborate: potassium thioacetate = 5:30:3:4, carbonization and activation in Ar atmosphere for 3h, then naturally cool the sample to room temperature;

[0057] S3: The sample in S2 was magnetically stirred for 12 hours, then suction filtered 4 times in absolute ethanol solution, then 6 times in deionized water, and finally dried for 6 hours to obtain the boron-sulfur co-doped spongy porous carbon, denoted as K 30 B 3 S 4 c.

[0058] S4, the resulting 50mg K 30 B 3 S 4 C. Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com