Passivation method of sulfuration type hydrocracking catalyst

A hydrocracking and catalyst technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, heterogeneous catalyst chemical elements, etc., can solve the problem of unstable and unsafe molecular sieve passivation process Health and environmental protection, can not guarantee the passivation effect and other issues, to achieve good temporary passivation effect, efficient and stable passivation effect, avoid the effect of passivation instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take 200g of oxidative hydrocracking catalyst, carry out sulfuration treatment outside the device, and convert it into sulfurized hydrocracking catalyst for future use.

[0028] Take 100g of sulfide-type hydrocracking catalyst, add 13.2g of tri-n-butylamine and 1.5g of dimethyl disulfide into diesel oil, stir evenly at 45°C to obtain a solution containing nitrogen and sulfur, and follow the method of pore saturation impregnation , introducing nitrogen and sulfur solution into sulfurized hydrocracking catalyst to introduce nitrogen content of 1.0% by weight and sulfur content of 1.0% by weight to obtain a catalyst loaded with nitrogen and sulfur; then at 40°C, under normal pressure, flowing Passivation treatment was carried out for 4 hours under air atmosphere to prepare passivated catalyst C1.

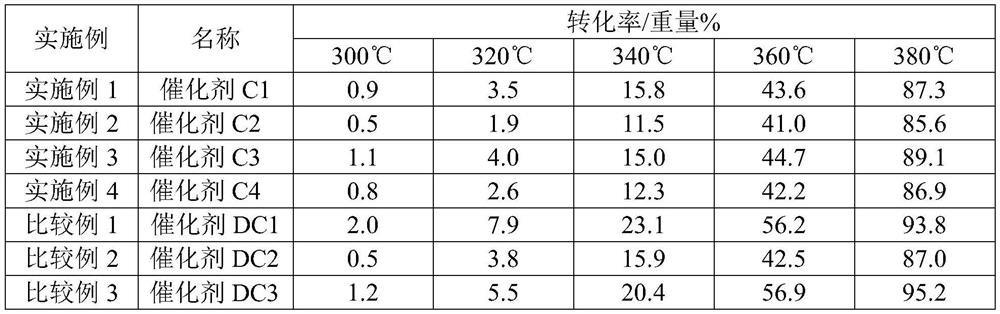

[0029] Put the passivated catalyst C1 into the reactor for reaction, when the temperature rises to 100°C, feed hydrogen and n-heptane raw materials, continue to raise the temper...

Embodiment 2

[0031] Take 100g of the same sulfurized hydrocracking catalyst as in Example 1, add 26.4g of tri-n-butylamine and 1.2g of carbon disulfide into the lubricating base oil, and stir evenly at 30°C to obtain a nitrogen- and sulfur-containing solution. Saturated impregnation method, introducing nitrogen and sulfur solution into sulfurized hydrocracking catalyst to introduce nitrogen content of 2.0% by weight and sulfur content of 1.0% by weight to obtain catalyst loaded with nitrogen and sulfur; then at 40°C, 0.1MPa Passivation treatment was carried out for 4 hours under pressure and in a non-flowing nitrogen atmosphere to prepare a passivated catalyst C2. The deactivated catalyst C2 was loaded into the reactor for reaction under the same reaction conditions as in Example 1, and its hydrocracking activity (expressed in the form of conversion rate) is shown in Table 1.

Embodiment 3

[0033] Get 100g of the same sulfurized hydrocracking catalyst as in Example 1, add 13.2g of dodecylamine and 0.75g of dimethyl disulfide into diesel oil, stir evenly at 60°C, and obtain a nitrogen- and sulfur-containing solution. Pore saturation impregnation, introducing nitrogen and sulfur solution into sulfurized hydrocracking catalyst to introduce nitrogen content of 1.0% by weight and sulfur content of 0.5% by weight to obtain a catalyst loaded with nitrogen and sulfur; then at 60°C, 0.1 Passivation treatment was carried out for 2 hours under MPa pressure and in a stagnant air atmosphere to prepare a passivated catalyst C3. The deactivated catalyst C3 was loaded into the reactor for reaction under the same reaction conditions as in Example 1, and its hydrocracking activity (expressed in the form of conversion rate) is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com