Lubricating oil composition for piston type air compressor

A kind of lubricating oil composition, air compressor technology, applied in the field of lubricating oil composition, piston air compressor lubricating oil composition field, can solve the problem of not involving the application of ionic liquid additive composition, etc., achieve good compatibility And synergistic effect, excellent high temperature stability, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] The composition of the piston air compressor lubricating oil composition is shown in Table 1, wherein the dosage of thiazole phosphate ionic liquid is 0.5wt%.

[0079] Table 1

[0080]

[0081]

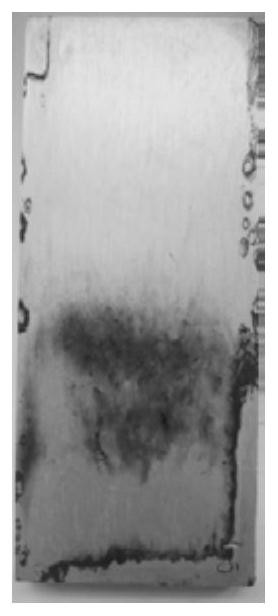

[0082] The lubricating oil compounded according to the components and their contents shown in Table 1 was subjected to a high-temperature coking plate test. The test conditions were as follows: short-term contact between heated lubricating oil (oil temperature 100°C) and high-temperature (310-320°C) aluminum plate Tendency to coke. After the high temperature coke plate test, the appearance is as follows: figure 1 shown.

Embodiment 2

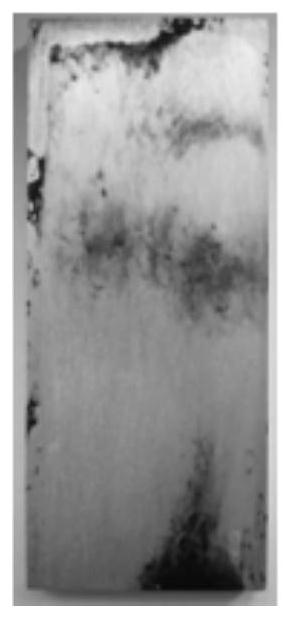

[0084] The difference from Example 1 lies in: the components and contents of the lubricating oil composition are shown in Table 2 for details. After the high temperature coke plate test, the appearance is as follows: figure 2 shown.

[0085] Table 2

[0086]

[0087]

Embodiment 3

[0089] The difference from Example 1 lies in: the components and contents of the lubricating oil composition are shown in Table 3 for details.

[0090] table 3

[0091]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com