Method for improving oil yield of microalgae in photoheterotrophic system

A technology of oil production rate and microalgae, which is applied in the field of improving oil production rate of microalgae under photoheterotrophic conditions, can solve the problems of low oil production rate of microalgae and the like, and achieve the effect of improving oil production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

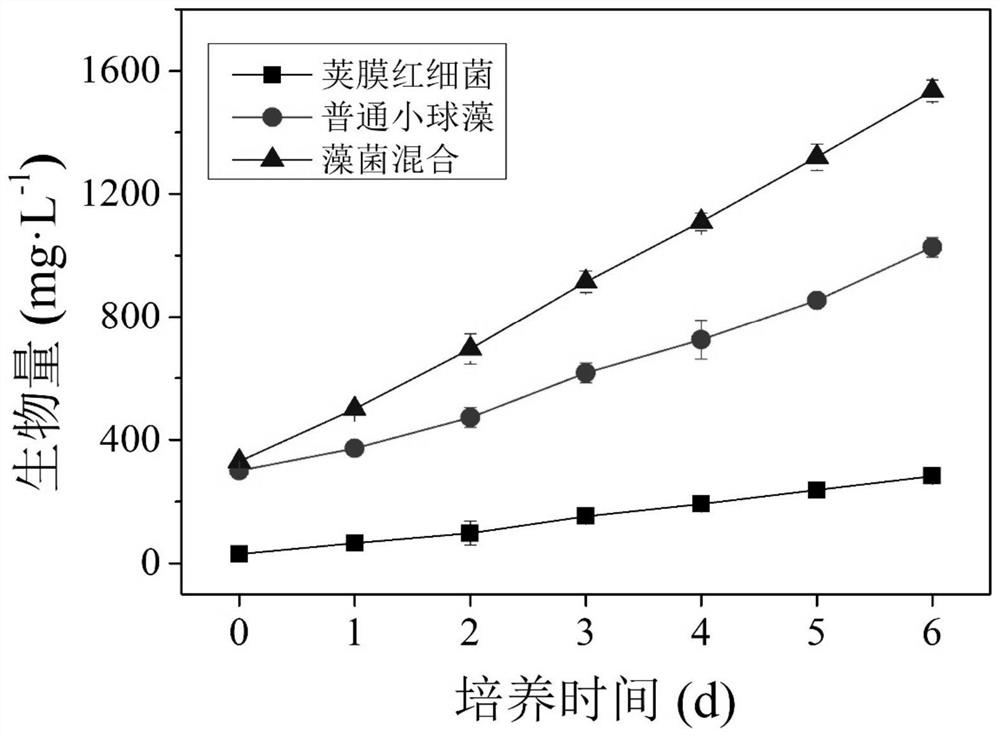

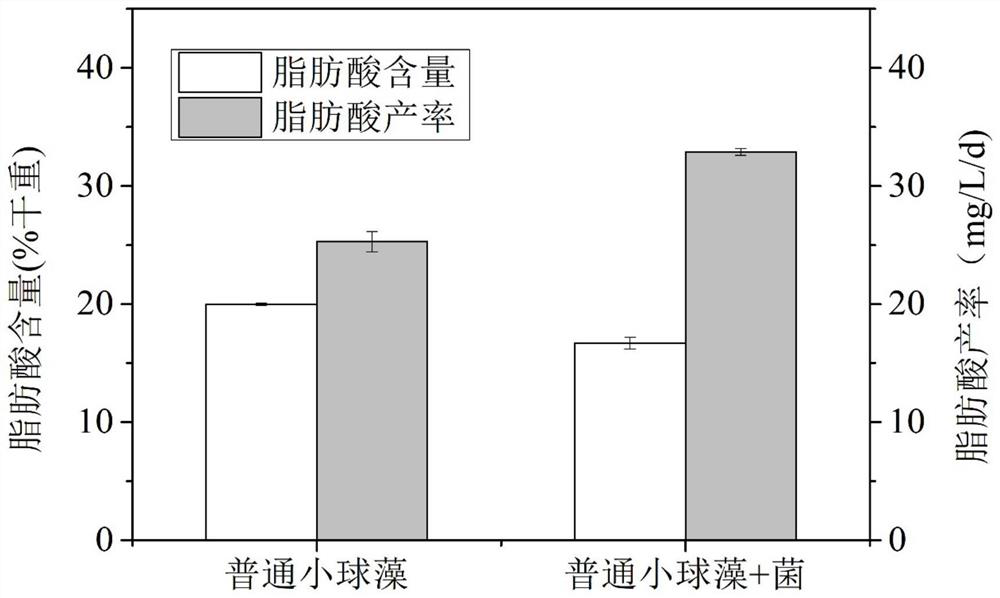

Embodiment 1

[0053] A method for improving the oil production rate of microalgae in photoheterotrophic system, comprising the following steps:

[0054] (1) Add the modified C medium into a 1L photosynthetic reactor, fill each bottle with 0.6L, and then sterilize it by high-pressure steam at 121°C for 20 minutes. Algae start autotrophic expansion culture, CO 2 The mixed gas with air enters the reactor after being sterilized by a 0.22μm filter at the top of the reactor, and the aeration rate is 0.5v / v / min, in which CO 2 The concentration is 4%, the temperature is controlled at 24±2°C, and the light intensity is 8000lux; the culture time is 7 days, and the microalgae are collected by centrifugation at 6000 rpm for 10 minutes after the culture is over, and the collected microalgae are suspended in the photoheterotrophic medium The microalgae liquid is obtained in the microalgae liquid, and the biomass in the microalgae liquid is 10-15g / L.

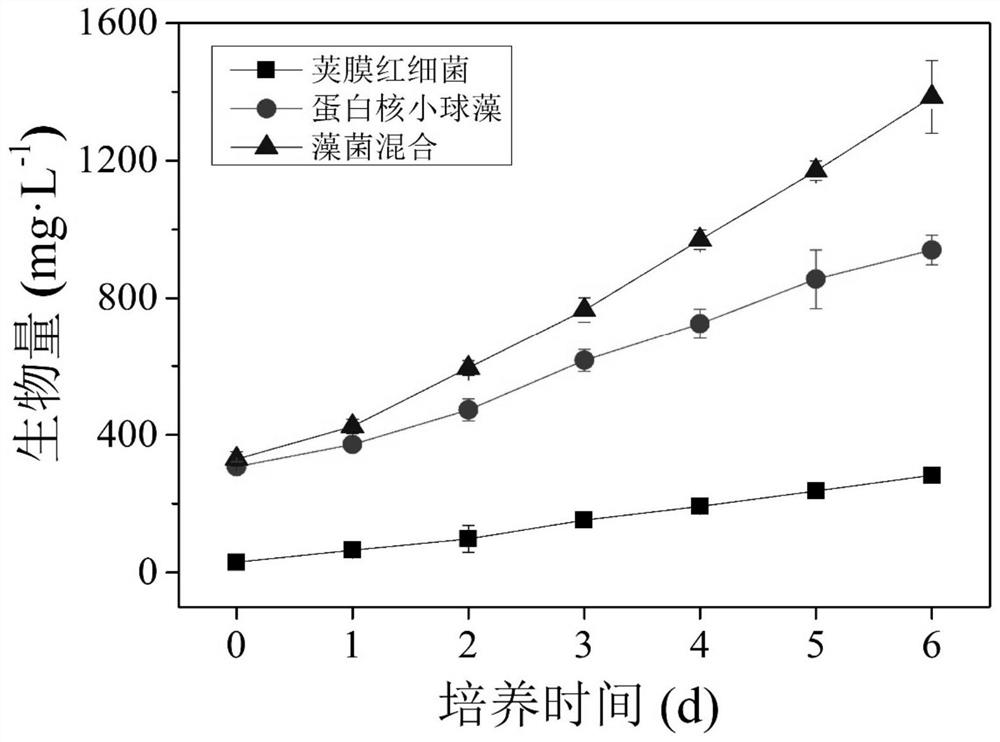

Embodiment 2

[0062] A method for improving the oil production rate of microalgae in photoheterotrophic system, comprising the following steps:

[0063] (1) Add the modified C medium into a 1L photosynthetic reactor, fill each bottle with 0.6L, and then sterilize by high-pressure steam at 121°C for 20 minutes. The algae started autotrophic expansion, CO 2 The mixed gas with air enters the reactor after being sterilized by a 0.22μm filter at the top of the reactor, and the aeration rate is 0.5v / v / min, in which CO 2 The concentration is 4%, the temperature is controlled at 24±2°C, and the light intensity is 8000lux; the culture time is 7 days, after the culture is completed, centrifuge at 6000 rpm for 10 minutes to collect Chlorella pyrenoidosa, and suspend the collected Chlorella pyrenoidosa The microalgae liquid is obtained in the photoheterotrophic culture medium, and the biomass in the microalgae liquid is 10-15g / L.

[0064] (2) Add 112Van Niel's yeast agar medium into a 250mL screw-nec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com