Housing construction coating layer structure with heat insulation and preservation functions

A technology for thermal insulation and coating layer, which is applied to building thermal insulation materials, thermal insulation, insulating layers, etc., can solve the problems of reduced service life, expansion and detachment of the coating layer, deformation of the coating layer, etc., achieves low heat conduction efficiency, and improves thermal insulation. , the effect of reducing the range of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

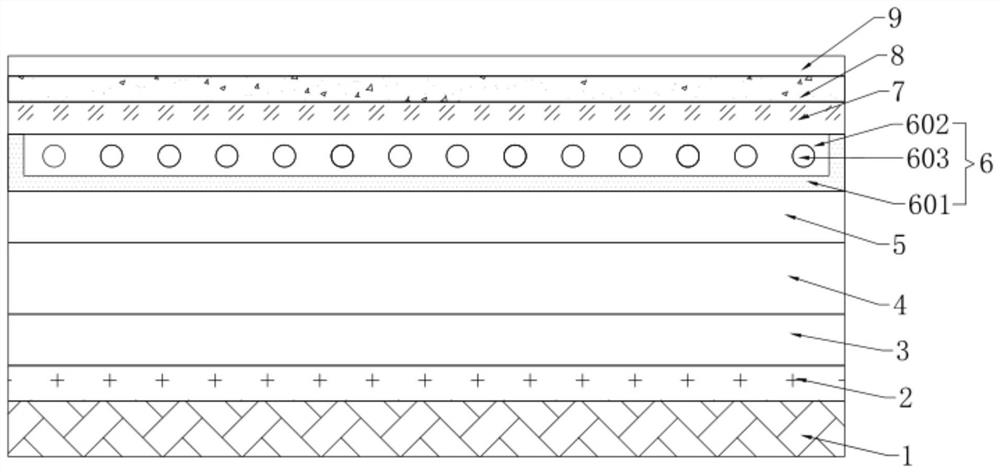

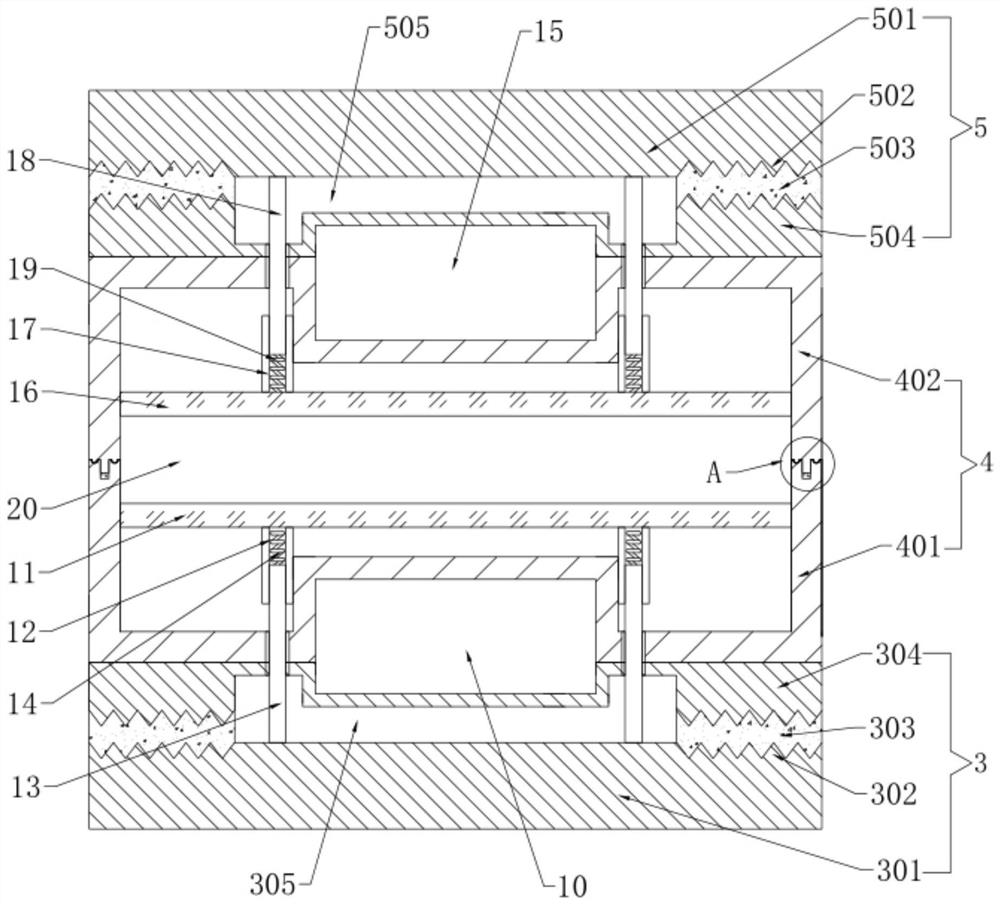

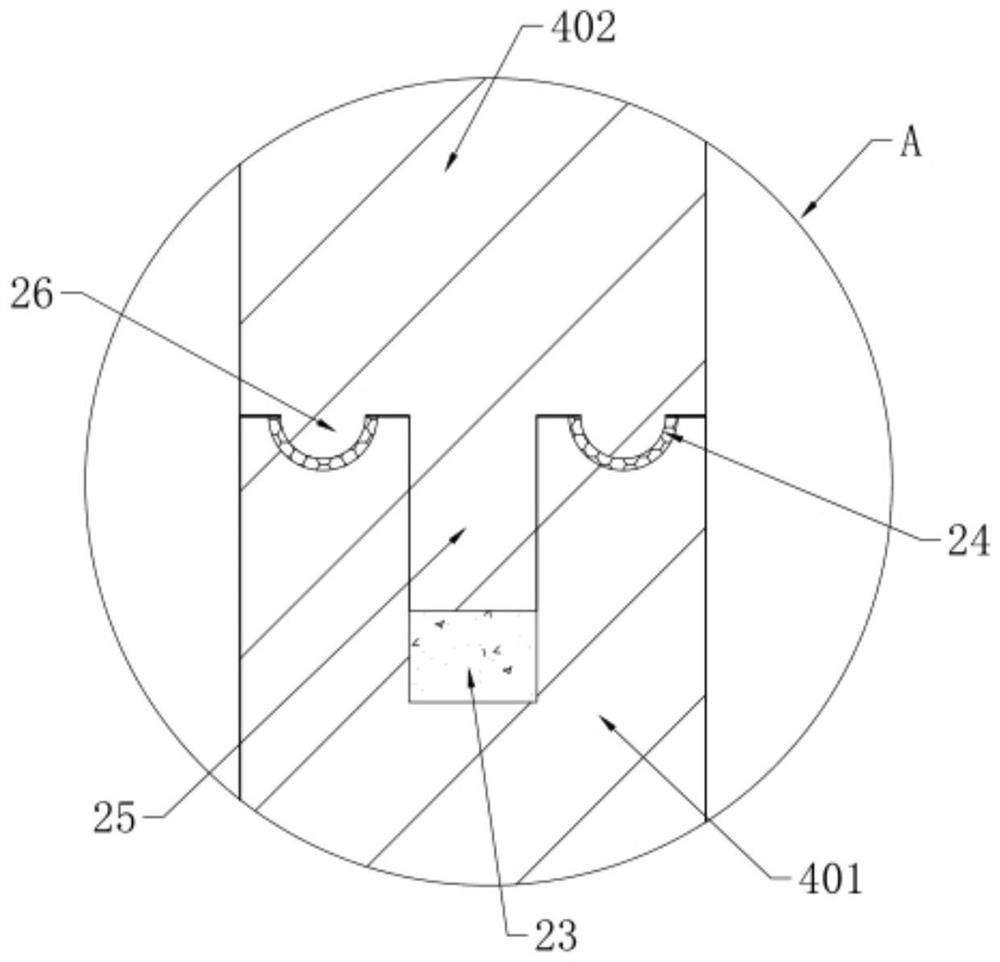

[0031] see Figure 1 to Figure 5 , the present invention provides a technical solution:

[0032] A building coating layer structure with thermal insulation function, comprising:

[0033] Inner wall base material 1, the outer side of the inner wall base material 1 is sequentially fixedly connected with a flexible putty layer 2, an inner elastic thermal insulation layer 3, a vacuum thermal insulation layer 4, an outer elastic thermal insulation layer 5, a reflective layer 6 and a waterproof layer 8, wherein , the flexible putty layer 2 plays the role of leveling the surface. By selecting light inorganic thermal insulation materials and high-quality elastic bonding resins, the appropriate powder ratio is determined to ensure that the product has good scraping workability and anti-crack and anti-falling capabilities. The inner elastic insulation layer 3, the vacuum insulation layer 4, and the outer elastic insulation layer 5 are combined with each other to form multiple vacuum ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com