Colorful multifunctional sun screen and preparation method thereof

A multi-functional, barrier cream technology, applied in pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve the problems of poor color brightness, poor skin compatibility, oil production, etc., to enhance weather resistance and stability , Good skin compatibility, enhance the effect of sunscreen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

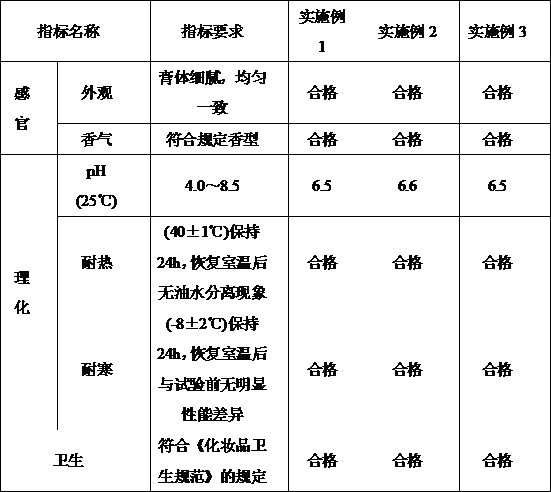

Examples

Embodiment approach 1

[0020] S1: Preparation of Surface-Modified Zinc Oxide / Attapulgite-Based Mayan Blue-Isatin Composite Pigment

[0021] (1) Mix 1 g of isatin and 10 g of purified attapulgite evenly, and bake in an oven at 150 °C for 36 h to obtain attapulgite-based Maya blue-isatin organic / inorganic hybrid pigments;

[0022] (2) Dissolve 0.2725 g of zinc acetate in 20 ml of absolute ethanol to form solution A; dissolve 0.2 g of linseed oil in 30 ml of absolute ethanol, and then add 10 g of attapulgite-like Maya blue-satin organic / Inorganic hybrid pigments were stirred at a constant temperature of 40°C to form suspension B; solution A was added dropwise to suspension B, stirred at 60°C for 12 h, centrifuged and ground to obtain linseed oil-modified zinc oxide / Attapulgite-based Mayan blue-indigo composite pigment.

[0023] S2: Preparation of colored multifunctional segregation cream

[0024] (1) Add 5 g of linseed oil-modified zinc oxide / attapulgite-based Mayan blue-indigo composite pigment i...

Embodiment approach 2

[0028] S1: Preparation of surface-modified zinc oxide / attapulgite-based Maya blue-acid red composite pigments

[0029] (1) Mix 1.5 g of commercially available cosmetic pigment acid red and 10 g of purified attapulgite evenly, and bake in an oven at 130 °C for 48 h to obtain an attapulgite-based Maya blue-acid red organic / inorganic hybrid pigment;

[0030] (2) Dissolve 0.545 g of zinc acetate in 20 ml of absolute ethanol to form solution A; dissolve 0.2 g of coconut oil in 30 ml of absolute ethanol, and then add 10 g of attapulgite-like Maya blue-acid red organic / Inorganic hybrid pigments were stirred at a constant temperature of 50 °C to form suspension B; solution A was added dropwise to suspension B, stirred at 60 °C for 12 h, centrifuged and ground to obtain coconut oil modified zinc oxide / attapulgite Base class Mayan blue-acid red composite pigment.

[0031] S2: Preparation of colored multifunctional segregation cream

[0032] (1) Add 5 g of coconut oil-modified zinc ox...

Embodiment approach 3

[0036] S1: Preparation of surface-modified zinc oxide / attapulgite-based Mayan blue-acid violet composite pigments

[0037] (1) Mix 1 g of commercially available cosmetic pigment acid violet and 10 g of purified attapulgite evenly, and bake in an oven at 150 °C for 36 h to obtain attapulgite-based Maya blue-acid violet organic / inorganic hybrid pigments;

[0038](2) Dissolve 0.2725 g of zinc acetate in 20 ml of absolute ethanol to form solution A; dissolve 0.2 g of grape seed oil in 30 ml of absolute ethanol, and then add 10 g of attapulgite-like Maya blue-acid violet organic / Inorganic hybrid pigments were stirred at a constant temperature of 40°C to form suspension B; solution A was added dropwise to suspension B, stirred at 60°C for 12 h, centrifuged and ground to obtain grape seed oil modified zinc oxide / Attapulgite-based Mayan blue-acid violet composite pigment.

[0039] S2: Preparation of colored multifunctional segregation cream

[0040] (1) Add 5 g of grape seed oil-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com