Ginseng fruit extracting solution and preparation process thereof

A technology of ginseng fruit and extract, which is applied in the field of ginseng fruit extract and its preparation, and can solve the problems of invalidation of active substances, thermal decomposition and hydrolysis of target substances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

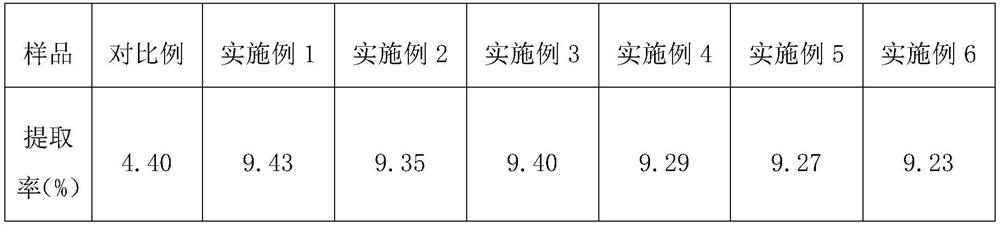

Examples

Embodiment 1

[0025] The present embodiment provides a kind of manufacturing process of ginseng fruit extract, comprising the following steps:

[0026] Grind the ginseng fruit into 200-mesh granules; add 75v / v% ethanol to the granules of the ginseng fruit, carry out reflux extraction at a temperature of 80°C for 80 minutes, and filter after extraction to obtain the filter residue and filtrate respectively; The filter residue obtained during flow extraction was used as raw material and extracted according to the steps of reflux extraction, and extracted three times in total; the filtrates obtained in the three times were mixed to obtain a mixed solution; the mixed solution was distilled under reduced pressure at 50°C to obtain a crude extract; the crude extract was Centrifuge and take the upper and middle layer solution to obtain the emulsion; use macroporous adsorption resin to absorb the emulsion with a volume flow rate of 1.5BV / h, and then elute with 60v / v% ethanol to obtain the active liq...

Embodiment 2

[0029] The present embodiment provides a kind of manufacturing process of ginseng fruit extract, comprising the following steps:

[0030] Grind the ginseng fruit into 180-mesh granules; add 70v / v% ethanol to the granules of ginseng fruit, carry out reflux extraction at a temperature of 75°C for 90 minutes, and filter after extraction to obtain the filter residue and filtrate respectively; The filter residue obtained during flow extraction was used as raw material and extracted according to the steps of reflux extraction, and extracted three times in total; the filtrates obtained in the three times were mixed to obtain a mixed solution; the mixed solution was distilled under reduced pressure at 45°C to obtain a crude extract; the crude extract was Centrifuge and take the upper and middle layer solution to obtain the emulsion; use the adsorption material to absorb the emulsion with a volume flow rate of 1.3BV / h, and then elute with 65v / v% ethanol to obtain the active liquid; the ...

Embodiment 3

[0033] The present embodiment provides a kind of manufacturing process of ginseng fruit extract, comprising the following steps:

[0034] Grind the ginseng fruit into 220-mesh granules; add 90v / v% ethanol to the granules of the ginseng fruit, carry out reflux extraction at a temperature of 78°C for 70 minutes, and filter after extraction to obtain the filter residue and filtrate respectively; The filter residue obtained during flow extraction was used as raw material and extracted according to the steps of reflux extraction, and extracted three times in total; the filtrates obtained in the three times were mixed to obtain a mixed solution; the mixed solution was distilled under reduced pressure at 48°C to obtain a crude extract; the crude extract was Centrifuge and take the upper and middle layer solution to obtain the emulsion; use macroporous adsorption resin to absorb the emulsion with a volume flow rate of 1.8BV / h, and then elute with 55v / v% ethanol to obtain the active liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com