Green and environment-friendly printing process method

A modified, alkyd resin technology, used in printing, printing devices, inks, etc., can solve the problems of low glossiness of printing patterns, poor printing quality, deterioration and cracking of printing marks, etc., achieving strong mechanical toughness, no cost waste, good gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

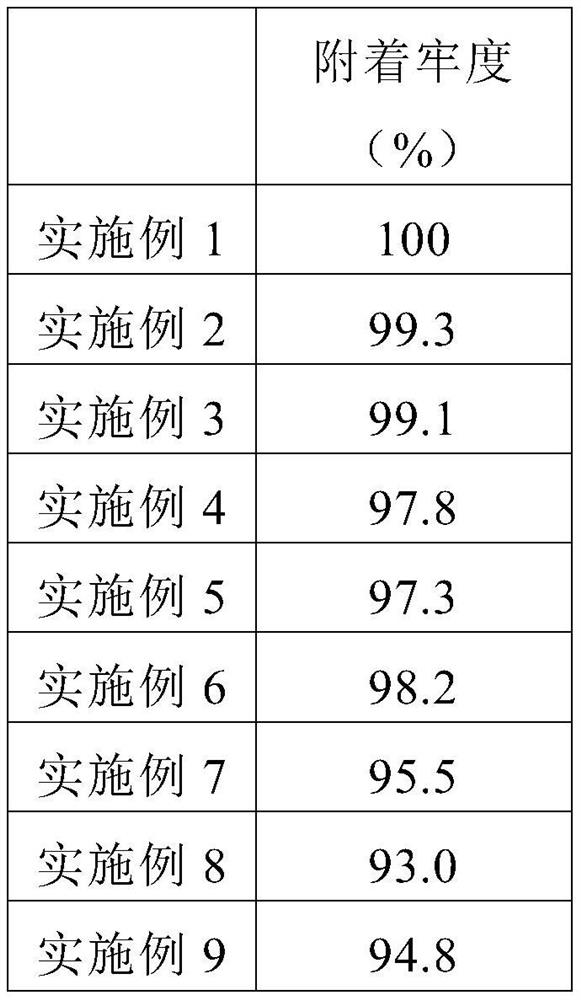

Examples

Embodiment 1

[0079] The green environmental protection printing process method comprises the following steps:

[0080] Q1 Determine the plate-making parameters: brick-type dots are used, the number of mesh lines is 22 / cm, and the plate-making depth is 100 μm;

[0081] Q2 plate making: columnar gravure is processed by laser engraving;

[0082] Q3 Trial printing: dip the ink onto the columnar gravure, and then perform trial printing and drying operations on the trial printing; judge whether it is necessary to re-prepare the ink or adjust the columnar gravure according to the obtained ink forming effect and printing quality specifications; if the ink forming effect and printing quality meet the specified printing standards, batch printing can be carried out according to the current gravure specifications and ink ratio;

[0083] Q4 printing: apply the ink on the entire plate surface of the columnar gravure, scrape off the excess ink on the surface of the columnar intaglio with a doctor blade ...

Embodiment 2

[0101] It is basically the same as Example 1, the only difference is:

[0102] The preparation method of described modified alkyd resin is:

[0103] D1 Mix 3 parts by weight of sulfonamide, 7 parts by weight of cellulose, and 18 parts by weight of ether, and then treat it at 85°C with an ultrasonic wave with a power of 350W and a frequency of 36kHz for 170min. Dry the filter residue for 8 hours at lower temperature to obtain modified cellulose;

[0104] D2 Mix the alkyd resin, the modified cellulose, acid anhydride, and anti-aging agent in a mass ratio of 65:22:8:2, then blend at 105°C for 105min at a speed of 800rpm, and extrude the particle size through an extruder 1mm blank;

[0105] D3 crushing the blank and passing it through a 2000 mesh screen to obtain the modified alkyd resin.

[0106] The sulfonamide is a mixture of N-methyl-N-nitroso-p-toluenesulfonamide and p-aminotoluene-o-sulfonanilide in a mass ratio of 3:2.

[0107] The cellulose is a mixture of cyanoethyl c...

Embodiment 3

[0111] It is basically the same as Example 1, the only difference is:

[0112] The preparation method of described modified alkyd resin is:

[0113] D1 Mix 3 parts by weight of sulfonamide, 7 parts by weight of cellulose, and 18 parts by weight of ether, and then treat it at 85°C with an ultrasonic wave with a power of 350W and a frequency of 36kHz for 170min. Dry the filter residue for 8 hours at lower temperature to obtain modified cellulose;

[0114] D2 Mix the alkyd resin, the modified cellulose, acid anhydride, and anti-aging agent in a mass ratio of 65:22:8:2, then blend at 105°C for 105min at a speed of 800rpm, and extrude the particle size through an extruder 1mm blank;

[0115] D3 crushing the blank and passing it through a 2000 mesh screen to obtain the modified alkyd resin.

[0116] The sulfonamide is a mixture of N-methyl-N-nitroso-p-toluenesulfonamide and p-aminotoluene-o-sulfonanilide in a mass ratio of 3:2.

[0117] The cellulose is a mixture of cyanoethyl c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com