Reduced graphene oxide polystyrene composite material and preparation method thereof

A composite material and polystyrene technology, applied in the field of reduced graphene oxide polystyrene composite material and its preparation, to achieve the effects of improving easy agglomeration, improving performance, and strong interface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

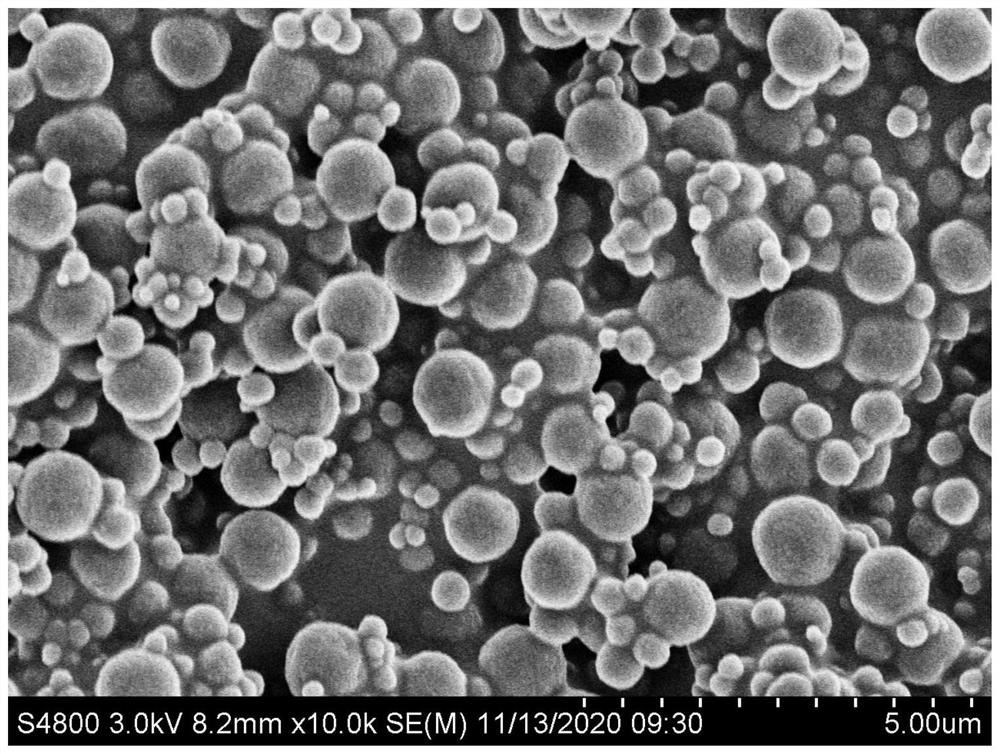

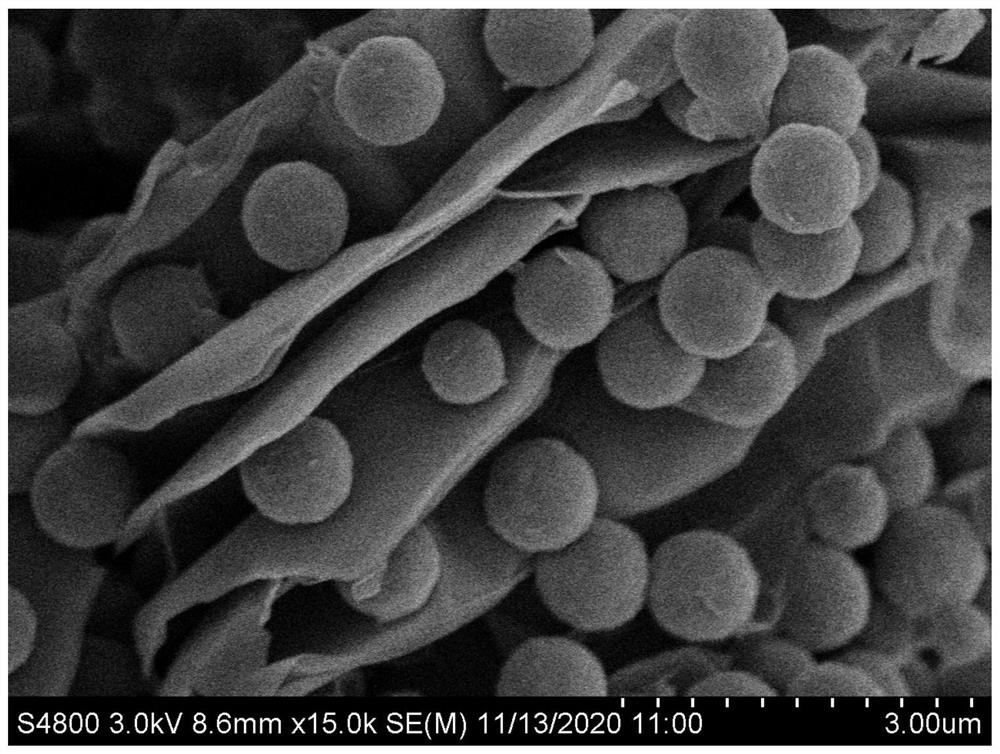

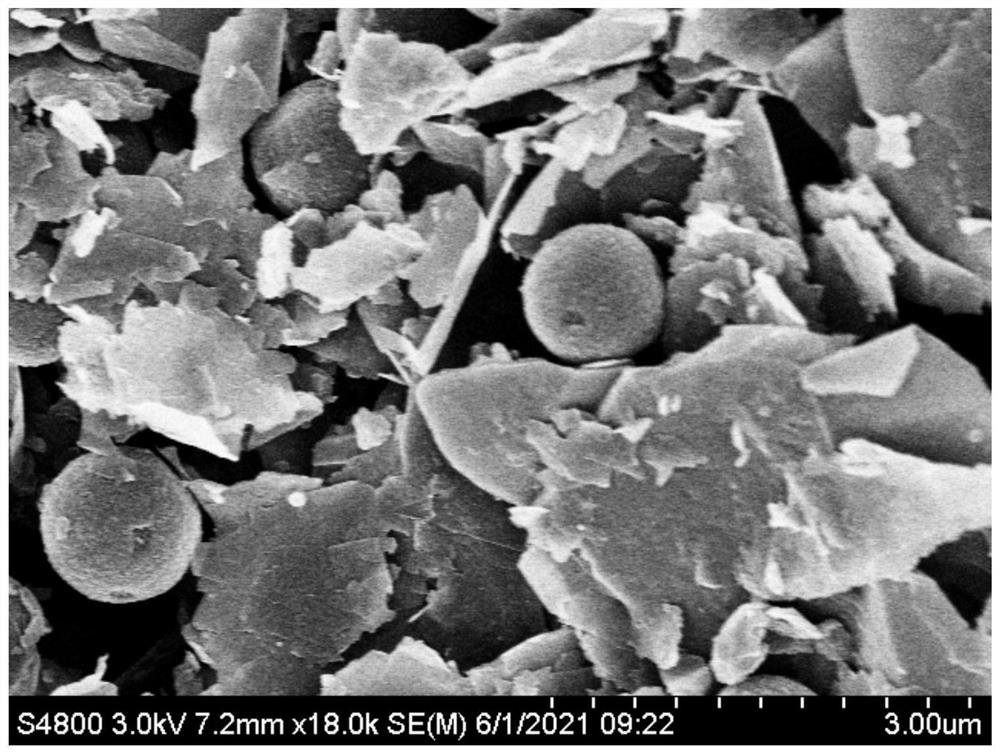

[0046] An embodiment of the present invention provides a reduced graphene oxide polystyrene composite material, the composite material is a pea-like pod structure, including cross-linked cationic polystyrene microspheres as peas and reduced graphene oxide as bean shells, wherein The mass ratio of reduced graphene oxide to crosslinked cationic polystyrene microspheres is 1:0.2.

[0047] The preparation method of above-mentioned composite material comprises the following steps:

[0048] Step 1, distilling styrene under reduced pressure, collecting fractions at 55-60°C to obtain styrene monomer;

[0049] Mix 0.56g of polyvinylpyrrolidone, 7.5mL of water and 42.5mL of absolute ethanol, sonicate for 5min, and pass through N 2 , to obtain the first reaction solution;

[0050] After mixing 7.94g styrene monomer and 0.08g azobisisobutylamidine hydrochloride, ultrasonic 5min, in N 2 Under protection, add to the above first reaction solution at 70°C and 150rpm and react for 2h to obtai...

Embodiment 2

[0055] An embodiment of the present invention provides a reduced graphene oxide polystyrene composite material, the composite material is a pea-like pod structure, including cross-linked cationic polystyrene microspheres as peas and the reduced graphene oxide as bean shells , wherein the mass ratio of reduced graphene oxide to crosslinked cationic polystyrene microspheres is 1:0.25.

[0056] The preparation method of above-mentioned composite material comprises the following steps:

[0057] Step 1, distilling styrene under reduced pressure, collecting fractions at 55-60°C to obtain styrene monomer;

[0058] Mix 0.66g of polyvinylpyrrolidone, 8mL of water and 46mL of absolute ethanol, sonicate for 4min, pass through N 2 , to obtain the first reaction solution;

[0059] After mixing 7.94g styrene monomer and 0.083g azobisisobutylamidine hydrochloride, ultrasonic 6min, in N 2 Under protection, add it to the first reaction solution above and react for 2.5 hours under the condit...

Embodiment 3

[0064] An embodiment of the present invention provides a reduced graphene oxide polystyrene composite material, the composite material is a pea-like pod structure, including cross-linked cationic polystyrene microspheres as peas and the reduced graphene oxide as bean shells , wherein the mass ratio of reduced graphene oxide to crosslinked cationic polystyrene microspheres is 1:0.5.

[0065] The preparation method of above-mentioned composite material comprises the following steps:

[0066] Step 1, distilling styrene under reduced pressure, collecting fractions at 55-60°C to obtain styrene monomer;

[0067] Mix 0.50g of polyvinylpyrrolidone, 7.5mL of water and 41mL of absolute ethanol, sonicate for 6min, and pass through N 2 , to obtain the first reaction solution;

[0068] After mixing 7.94g styrene monomer and 0.076g azobisisobutylamidine hydrochloride, ultrasonic 5min, in N 2 Under protection, add to the above first reaction solution at 72°C and 150rpm and react for 1.5h ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com