A kind of polymer water-based paint and preparation method thereof

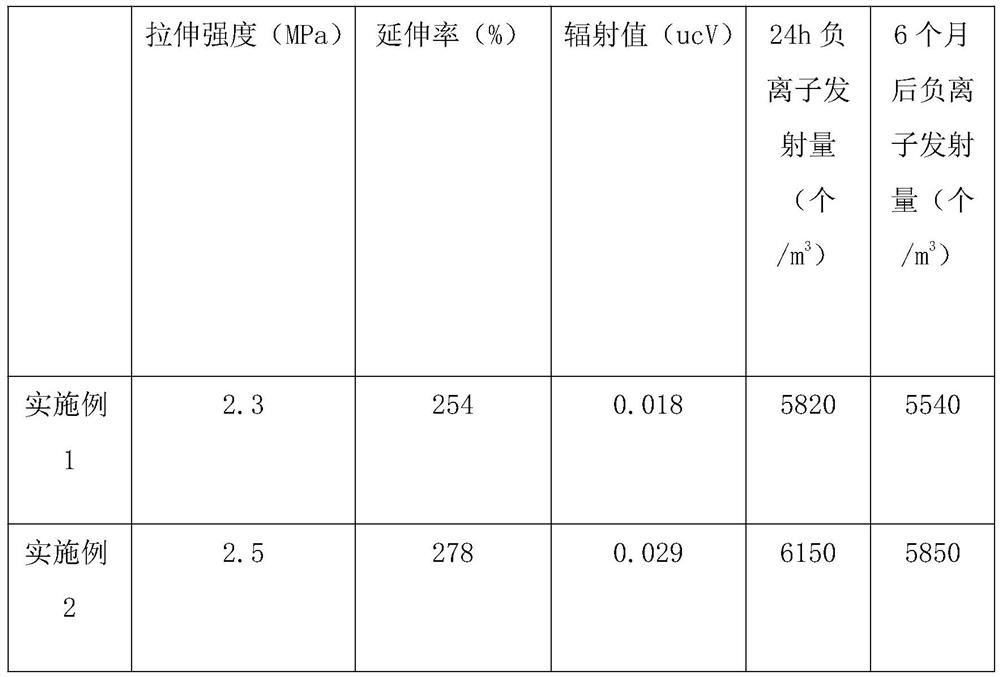

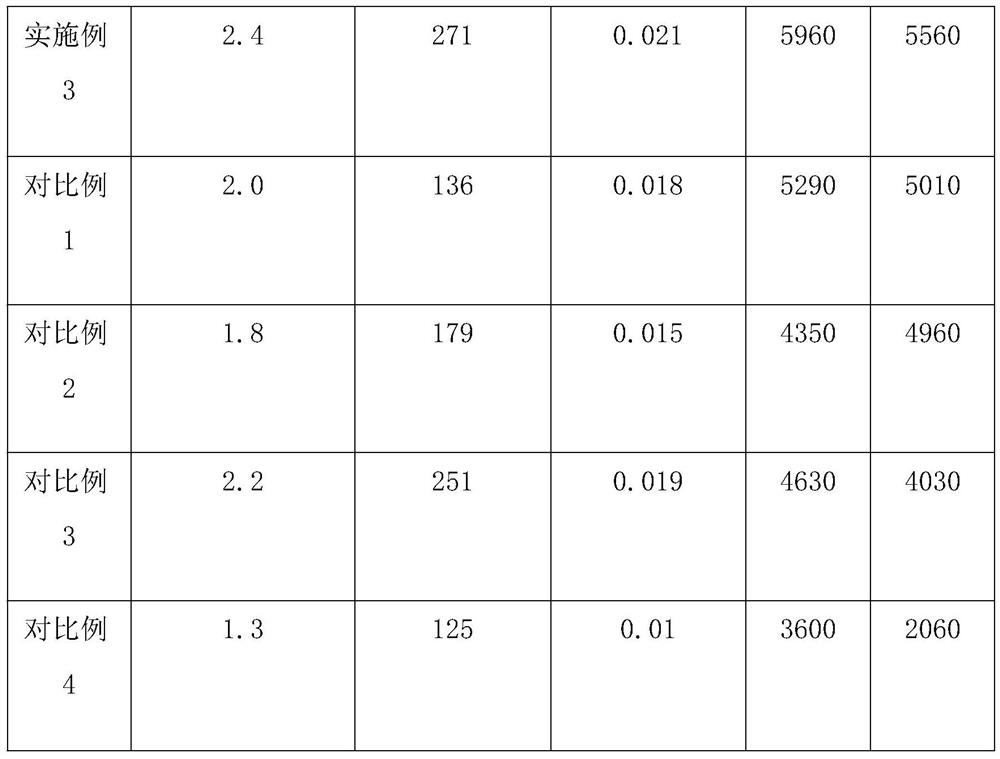

A water-based coating and polymer technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of low tensile strength of coatings, short duration of negative ion release, small elongation, etc., to achieve uniform force, large ratio Effect of Surface Area, Increased Tensile Strength and Elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method of a polymer water-based paint, comprising the following steps:

[0026] (1) Take the fullerene powder in a mass ratio of 1:20-30, add ethanol solution with a volume fraction of 70%, stir magnetically at 350-550r / min for 12-15h, and add lithium 3-5 times the mass of the fullerene powder 30-50% of barium sulfate by mass of algae and fullerene powder is mixed, ultrasonically dispersed for 20-40min, to obtain ultrasonic dispersion material, take the ultrasonic dispersion material and dry, calcined at 500-700 ℃ for 3-5h under vacuum conditions, the calcined The product is ground through a 200-mesh sieve to obtain a fullerene activator;

[0027] (2) Take the hexacyclic stone and pulverize it in an ultra-fine pulverizer to achieve a particle size of 400-700 μm, mix the fullerene activator and the hexagonal stone powder uniformly according to the mass ratio of 1:80-100, and put it into a plasma chamber for Plasma treatment is carried out for 1-800s to obt...

Embodiment 1

[0030] A polymer water-based paint, comprising the following raw materials:

[0031] Fullerene activator, hexacyclolite, barium sulfate, water-based polyurethane resin, wherein the mass ratio of fullerene activator and hexacyclolite micropowder is 1:80. The polyvinyl alcohol material is enveloped with α-cyclodextrin, and the α-cyclodextrin accounts for 10% of the mass of the polyvinyl alcohol material.

[0032] A preparation method of a polymer water-based paint, comprising the following steps:

[0033] (1) Take fullerene powder and add ethanol solution with a volume fraction of 70% at a mass ratio of 1:20, stir magnetically at 350 r / min for 12 h, and add 3 times the mass of fullerene powder with hectorite and fullerene powder mass 30% barium sulfate was mixed, and ultrasonically dispersed for 20 minutes to obtain ultrasonic dispersion material. The ultrasonic dispersion material was dried and calcined at 500 °C for 3 hours under vacuum conditions. The calcined product was gr...

Embodiment 2

[0037]A polymer water-based paint, comprising the following raw materials:

[0038] Fullerene activator, hexacyclolite, barium sulfate, water-based polyurethane resin, wherein, the mass ratio of fullerene activator and hexacyclolite micropowder is 1:100. The polyvinyl alcohol material is enveloped with α-cyclodextrin, and the α-cyclodextrin accounts for 15% of the mass of the polyvinyl alcohol material.

[0039] A preparation method of a polymer water-based paint, comprising the following steps:

[0040] (1) Take fullerene powder and add ethanol solution with a volume fraction of 70% at a mass ratio of 1:30, stir magnetically at 550 r / min for 15 h, and add 5 times the mass of fullerene powder with hectorite and fullerene powder mass 50% barium sulfate was mixed, and ultrasonically dispersed for 40 minutes to obtain ultrasonic dispersion material. The ultrasonic dispersion material was dried and calcined at 700 °C for 5 h under vacuum conditions. The calcined product was groun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com