A kind of production method of high temperature resistant insulating cardboard

A technology of insulating cardboard and production methods, which is applied in the direction of insulators, organic insulators, plastic/resin/wax insulators, etc., can solve the problems of reduced service life and reduced service life, achieve firm bonding, improve cleanliness, and improve slurry uniformity degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

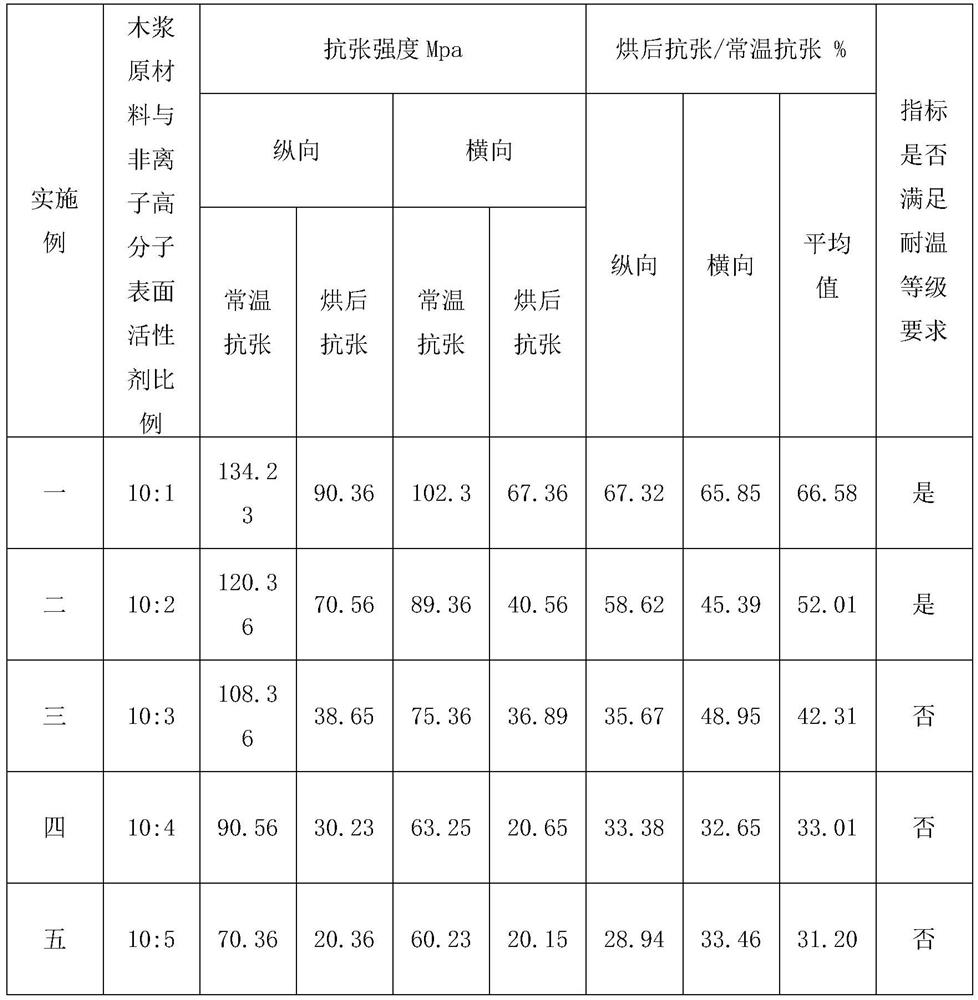

[0033] Embodiment one: Production of 3.0mm cardboard

[0034] S1. Raw material selection

[0035] Meta-chopped aramid fiber, length 2.5mm; pure imported 100% unbleached kraft softwood pulp (Swedish electronic grade aspar wood pulp, Canadian electronic grade Prince George wood pulp), fiber length 3mm, wall thickness 2.5 um, fiber diameter 0.03mm, ash content 0.3%, conductivity 3.0mS / m.

[0036] S2, the disintegration of pulp (pulping)

[0037] a. Put 1200kg of pure imported 100% unbleached kraft softwood pulp (600kg Aspar + 600kg Prince George) into the D-type hydraulic pulper, and add 22800kg of pure water with a conductivity lower than 18uS / cm to make The slurry concentration after mixing was 5%. Turn on the D-type water conservancy pulper, after dissolving the pulp board into fibers, turn on the pulp pump, pump it to the fore-milling tank A, and let it stand for 2 hours, so that the fibers are fully swollen in the pure water environment. Subsequently, according to the p...

Embodiment 2

[0048] Embodiment two: The second production of 3.0mm cardboard

[0049] In the production process of this example, the ratio of wood pulp raw material and non-ionic polymer surfactant (the sum of acrylamide + water-soluble phenolic resin) is adjusted to 10:2, the concentration of 120kg is 8.0% acrylamide, and the concentration of 120kg is 10%. The water-soluble phenolic resin; the remaining process conditions are the same as in Example 1.

Embodiment 3

[0050] Embodiment three: The third production of 3.0mm cardboard

[0051] In the production process of this example, the ratio of wood pulp raw material and non-ionic polymer surfactant was adjusted to 10:3, and 180 kg of water-soluble phenolic resin with a concentration of 8.0% acrylamide and 180 kg of acrylamide with a concentration of 10% was added; the rest of the process conditions remained unchanged. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com