Balanced heating type resistance furnace

A resistance furnace and heating technology, applied in the direction of electric furnace heating, furnace, furnace type, etc., can solve the problems affecting the balance of the resistance furnace temperature, reduce the working efficiency of the resistance furnace, reduce the gas fluidity in the furnace, etc., to improve environmental protection. , the effect of improving heat conduction efficiency and improving transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

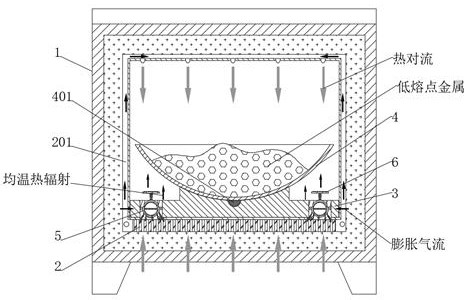

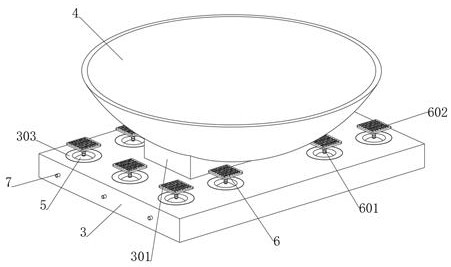

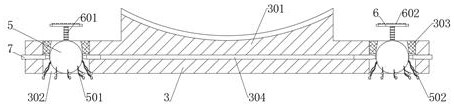

[0043] see Figure 1-10 , a balanced heating type resistance furnace, including a resistance furnace body 1 and an electric heating element 2 installed at the bottom of the resistance furnace body 1, the inner wall of the resistance furnace body 1 is provided with a heat convection channel 201 matched with the electric heating element 2, the resistance furnace body 1. The lower inner wall is fixedly connected with a zoned uniform temperature plate 3 located on the upper side of the electric heating element 2. There are multiple uniform temperature adjustment holes 302 in the zoned uniform temperature plate 3. There are multiple uniform temperature adjustment holes in the zoned uniform temperature plate 3. 302 is connected to the air equalizing hole 304, and the air drum type support bag 5 is arranged in the uniform temperature regulating hole 302, and the left and right ends of the air drum type support bag 5 are fixedly connected with the hot air circulation pipe 7, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com