Method for observing Al5FeSi phase in aluminum-silicon coating original plate alloy layer

An alloy layer and coating technology is applied in the field of observation of the Al5FeSi phase in the alloy layer of the aluminum-silicon coating original plate, which can solve the problem of high cost and achieve the effect of low detection cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

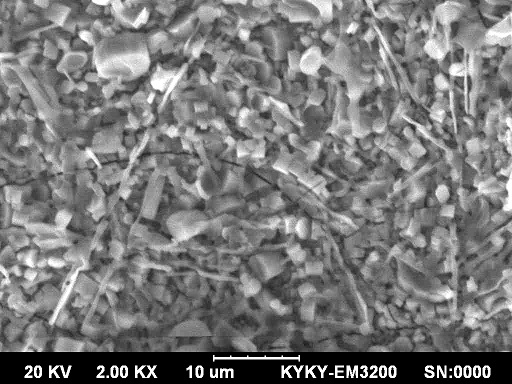

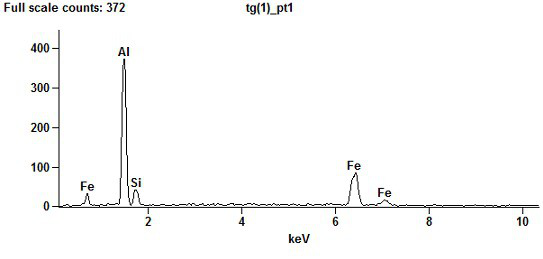

[0053] Al in a kind of aluminum-silicon coating raw plate alloy layer 5 The observation method of FeSi phase includes sample preparation, chemical corrosion, cleaning, scanning electron microscope observation and energy spectrometer measurement, specifically:

[0054] (1) Sample preparation: Take an aluminum-silicon coated steel plate (1500+AS grade), cut a sample of 15mm×15mm, put the sample coating surface horizontally into the mounting machine for mounting, and the mounting surface of the sample coating is completely exposed , and then perform polishing treatment, specifically: spray water and 2.5 μm high-efficiency metallographic polishing agent evenly on a 200mm pressure-sensitive vinyl polishing cloth in sequence, and then polish for 15s at a polishing machine speed of 600 rpm.

[0055] (2) Chemical corrosion: Put the sample prepared in step (1) into the corrosion solution for chemical corrosion. The corrosion solution consists of 0.03g / ml stannous chloride aqueous solut...

Embodiment 2

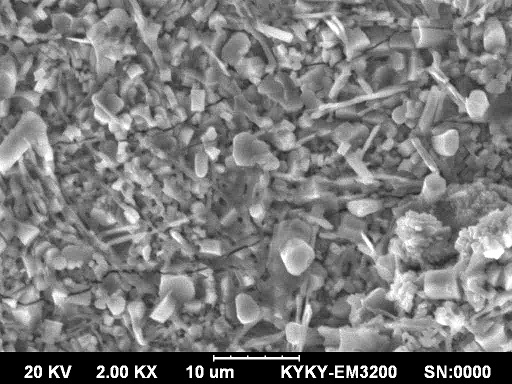

[0060] Al in a kind of aluminum-silicon coating raw plate alloy layer 5 The observation method of FeSi phase includes sample preparation, chemical corrosion, cleaning, scanning electron microscope observation and energy spectrometer measurement, specifically:

[0061] (1) Sample preparation: Take an aluminum-silicon coated steel plate (DC52D+AS grade), cut a 20mm×20mm sample, put the sample coating surface horizontally into the mounting machine for mounting, and the mounting surface of the sample coating is completely exposed , and then perform polishing treatment, specifically: spray water and 0.5 μm high-efficiency metallographic polishing agent evenly on a 250mm pressure-sensitive vinyl polishing cloth in sequence, and then polish for 20s at a polishing machine speed of 600 rpm.

[0062] (2) Chemical corrosion: Put the sample prepared in step (1) into the corrosion solution for chemical corrosion. The corrosion solution consists of 0.02g / ml stannous chloride aqueous solutio...

Embodiment 3

[0067] Al in a kind of aluminum-silicon coating raw plate alloy layer 5 The observation method of FeSi phase includes sample preparation, chemical corrosion, cleaning, scanning electron microscope observation and energy spectrometer measurement, specifically:

[0068] (1) Sample preparation: Take an aluminum-silicon coated steel plate (DC51D+AS grade), cut a 10mm×10mm sample, put the sample coating surface horizontally into the mounting machine for mounting, and the mounting surface of the sample coating is completely exposed , and then perform polishing treatment, specifically: spray water and 1.5 μm high-efficiency metallographic polishing agent evenly on the 200mmmm pressure-sensitive vinyl polishing cloth in sequence, and then polish for 15s at the speed of the polishing machine at 900 rpm.

[0069] (2) Chemical corrosion: Put the sample prepared in step (1) into the corrosion solution for chemical corrosion. The corrosion solution consists of 0.05g / ml stannous chloride aq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com