PCB defect detection method based on YOLOv5

A defect detection and defect technology, which is applied in neural learning methods, image data processing, image enhancement, etc., can solve the problems of increasing domestic enterprise costs, detection size limitations, unfavorable development, etc., and achieve excellent performance, high accuracy, The effect of high accuracy and generalization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

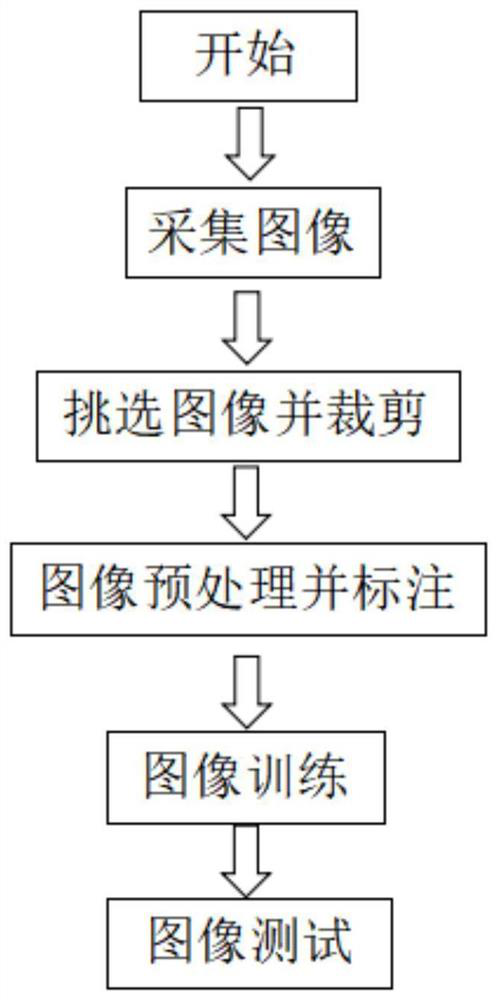

[0063] see Figure 1-11 , a PCB defect detection method based on YOLOv5, including the following steps:

[0064] Step 1. Collect images and take pictures of the produced PCB;

[0065] Step 2: Select and crop the image, select, crop and increase the brightness of the PCB image containing defects.

[0066] Step 3: Image preprocessing and labeling, use the obtained sub-images to perform data enhancement, and construct a training sample set, a verification sample set, and a test sample set;

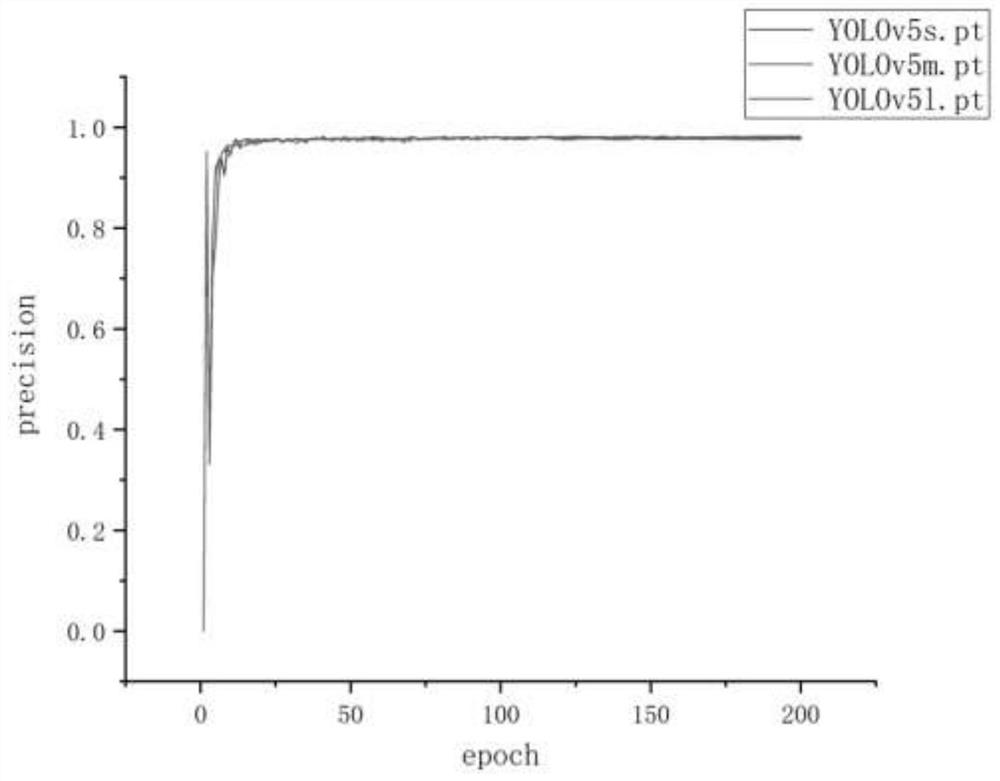

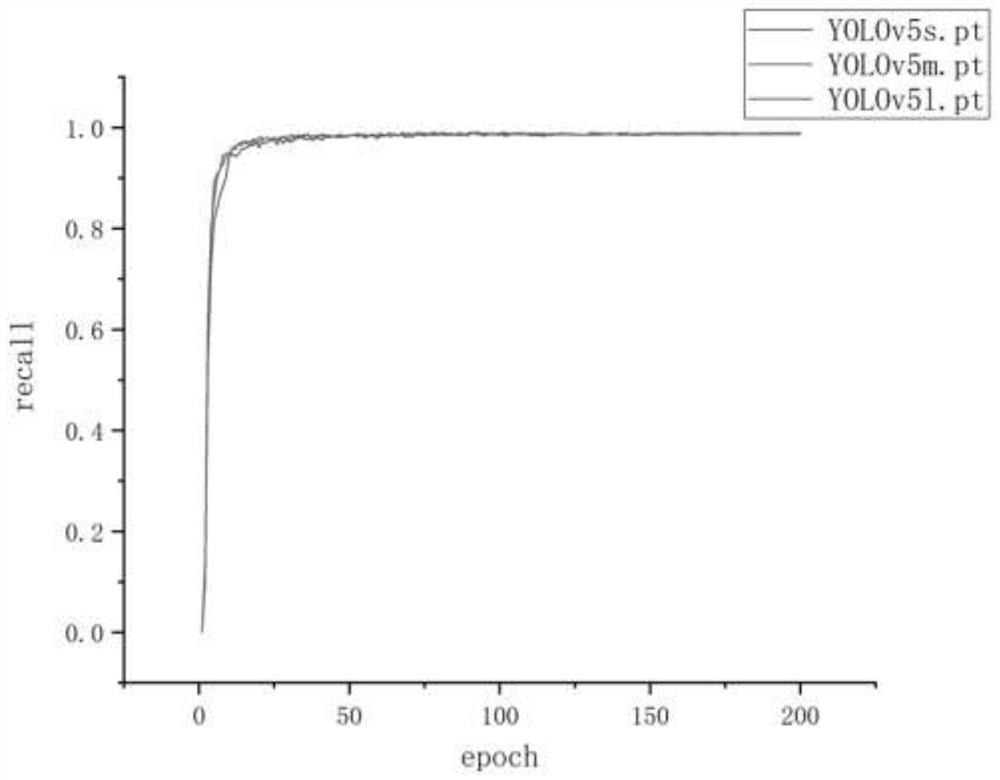

[0067] Step 4, image training, use the constructed training sample set and verification sample set to train YOLOv5 weights and verify the trained YOLOv5 model;

[0068] Step 5, image test, use the trained YOLOv5 model to detect the PCB image of the test set, and analyze the detection results.

[0069] In the embodiment of the present invention, the step 1 specifically includes the following steps:

[0070] a. Equipped with high-definition line scan cameras in the PCB production line;

[...

Embodiment 2

[0093] see figure 1 , a PCB defect detection method based on YOLOv5, including the following steps:

[0094] Step 1. Collect images and take pictures of the produced PCB;

[0095] Step 2: Select and crop the image, select, crop and increase the brightness of the PCB image containing defects.

[0096] Step 3, image preprocessing and labeling, use the obtained sub-images to perform data enhancement, and construct training sample sets, verification sample sets, and test sample sets;

[0097] Step 4, image training, use the constructed training sample set and verification sample set to train YOLOv5 weights and verify the trained YOLOv5 model;

[0098] Step 5, image test, use the trained YOLOv5 model to detect the PCB image of the test set, and analyze the detection results.

[0099] In the embodiment of the present invention, the detection method adopts the YOLOv5 target detection algorithm, which specifically includes:

[0100] 1. Mosaic data enhancement. The input end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com