Steel plate inner surface defect identification method based on fractional order wavelet transform

A technology of wavelet transform and defect recognition, applied in character and pattern recognition, genetic rules, image analysis, etc., can solve problems such as obstacles to popularization and use, false detection, ultrasonic detection automation, and intelligent obstacles, so as to improve detection efficiency and Accuracy, avoiding imprecise physical meaning, and outstanding generalization ability

Pending Publication Date: 2021-10-22

SOUTHWEST PETROLEUM UNIV

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Nevertheless, ultrasonic testing technology also has some shortcomings and disadvantages that hinder its further promotion and use. Traditional ultrasonic testing technology needs to rely on the professional skills and experience of operators to analyze the detection echo signal. Subjectivity and uncertainty make it possible not only to cause missed and false detections during the ultrasonic testing process, but also to accurately analyze the position, depth, and shape of defects, which makes the post-maintenance and maintenance of related equipment difficult. It has caused a certain degree of difficulty, and it has also become a major obstacle to the automation and intelligence of ultrasonic testing. Therefore, accurate quantitative and qualitative analysis of defects has become an urgent problem in the field of ultrasonic testing.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

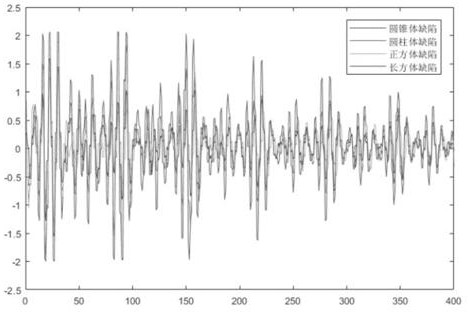

[0080] The method will be described below in conjunction with specific examples, and the parameters of the inner surface defects of the steel plate are shown in Table 1:

[0081] Table 1 embodiment defect size parameter

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

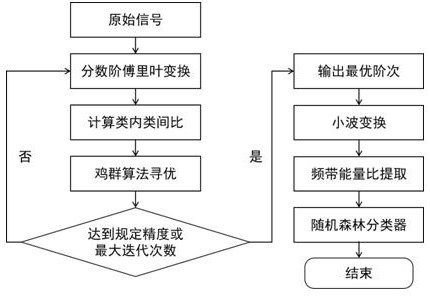

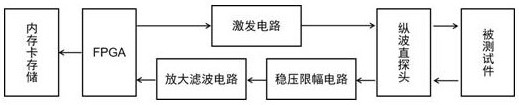

The invention discloses a steel plate inner surface defect identification method based on fractional order wavelet transform, which is used for improving the detection accuracy of the shape and depth of the steel plate inner surface defect by using a signal processing method. The method comprises the following steps: collecting and storing an ultrasonic detection signal of the steel plate inner surface defect through a related sensor; performing fractional order Fourier transform on the obtained related signals, searching an optimal fitness value through a chicken flock algorithm by using an inter-class and intra-class distance ratio as a fitness function so as to realize optimal order selection of the fractional order Fourier transform, and then performing wavelet transform on the processed signals; taking the energy ratio of each component obtained by decomposition as a feature vector matrix, and testing a test sample set by using a random forest classification model, and the result shows that the shape and depth of the steel plate inner surface defect can be effectively identified.

Description

technical field [0001] The invention relates to the field of steel plate defect detection, in particular to an ultrasonic detection signal recognition method based on fractional wavelet transform. Background technique [0002] With the further improvement of social productivity, the country will invest more resources and energy in the field of industrial production. Steel plates play a pivotal role in various departments of national production, which ensures that related production, transportation and other equipment play their roles in their respective fields. Therefore, detecting and early warning of steel plate defects and ensuring the safe and stable operation of equipment have a vital impact on social production and life. Especially for related steel equipment in the petrochemical industry, due to the high temperature and humidity of the working environment and the high sulfur and high acid working medium, the surface of the steel plate is prone to complex physical and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G06T7/00G06K9/62G06N3/00G06N3/12

CPCG06T7/0002G06N3/006G06N3/126G06T2207/10004G06T2207/20064G06T2207/30136G06F18/24323G06F18/214Y02P90/30

Inventor 韦明辉江丽霞涂凤秒姜蓬勃

Owner SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com