Solid secondary battery and method for manufacturing same

A technology of secondary batteries and manufacturing methods, applied in the field of machines, products or compositions, and processes, capable of solving problems such as liquid leakage, high cost, and fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

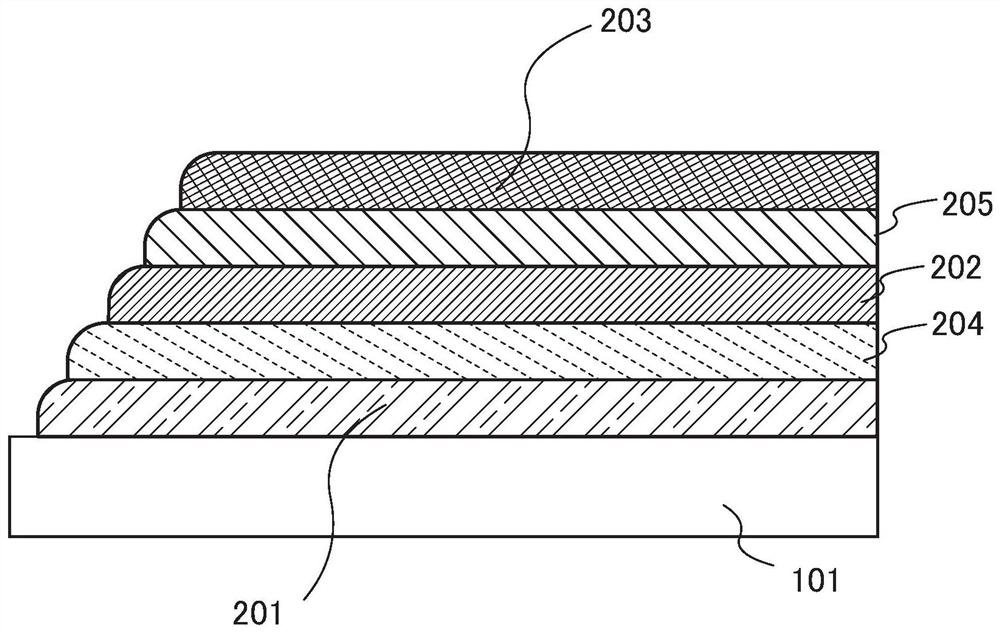

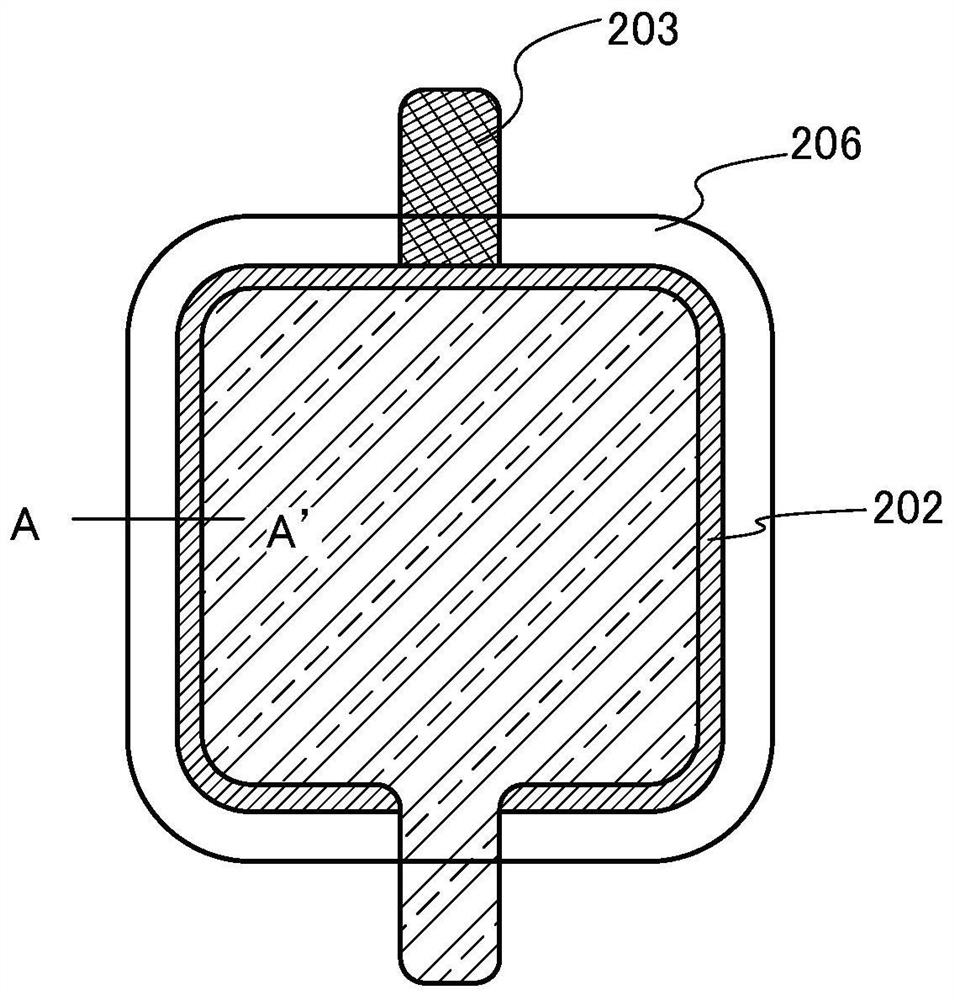

[0058] figure 1 It is one of the embodiments showing the case where the thin-film solid-state secondary battery is a single-layer unit. Note that, in this specification, a single-layer unit of a solid secondary battery refers to a group including at least a positive electrode, a solid electrolyte layer, and a negative electrode.

[0059] exist figure 1 In the single-layer unit shown, a positive electrode 201 , a positive electrode active material layer 204 , a solid electrolyte layer 202 , a negative electrode active material layer 205 , and a negative electrode 203 are sequentially stacked on a substrate 101 . Notice, figure 1 The shown cross-sectional view is only a part, and it is arranged so that the planar area of the positive electrode is smaller than that of the negative electrode. In addition, the ends are rounded, at figure 1 Only one of the ends is shown.

[0060] Examples of the substrate 101 include ceramic substrates, glass substrates, plastic substrates, s...

Embodiment approach 2

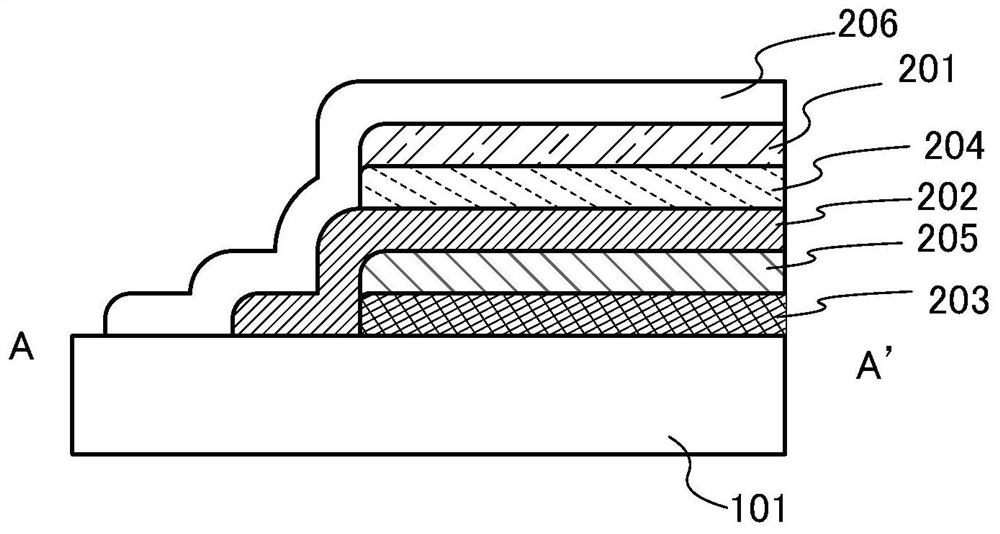

[0084] An example of a single-layer unit was shown in Embodiment 1, but an example of a multi-layer unit is shown in this embodiment. Figure 4 and Figure 5 It is one of the embodiments showing the case where the thin-film solid-state secondary battery is a multilayer unit.

[0085] Figure 4 An example of a section of a three-story unit is shown.

[0086] A positive electrode 201 is formed on a substrate 101, and a positive electrode active material layer 204, a solid electrolyte layer 202, a negative electrode active material layer 205, and a negative electrode 203 are sequentially formed on the positive electrode 201, thereby constituting the first unit.

[0087] Furthermore, a second negative electrode active material layer, a second solid electrolyte layer, a second positive electrode active material layer, and a second positive electrode are sequentially formed on the negative electrode 203 , thereby constituting the second unit.

[0088] Furthermore, a third layer o...

Embodiment approach 3

[0094] Figure 6A This is an external view of a thin-film solid-state secondary battery. The secondary battery 913 includes a terminal 951 and a terminal 952 . Terminal 951 is electrically connected to the positive pole, and terminal 952 is electrically connected to the negative pole.

[0095] Figure 6B This is the external view of the battery control circuit. Figure 6B The battery control circuit shown includes substrate 900 and layer 916 . A circuit 912 and an antenna 914 are disposed on the substrate 900 . The antenna 914 is electrically connected to the circuit 912 . Terminal 971 and terminal 972 are electrically connected to circuit 912 . The circuit 912 is electrically connected to the terminal 911 .

[0096] The terminal 911 is connected to, for example, a device supplied with power from a thin-film solid state secondary battery. For example, the terminal 911 is connected to a display device, a sensor, and the like.

[0097] The layer 916 has, for example, a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com