Novel process and device for treating carnallite

A process and a new type of technology, applied in the field of a new process and device for treating miscellaneous salts, can solve the problems of reducing the curing effect, high cost, and high requirements for equipment and materials, and achieve harmless treatment, stable curing quality, and obvious economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

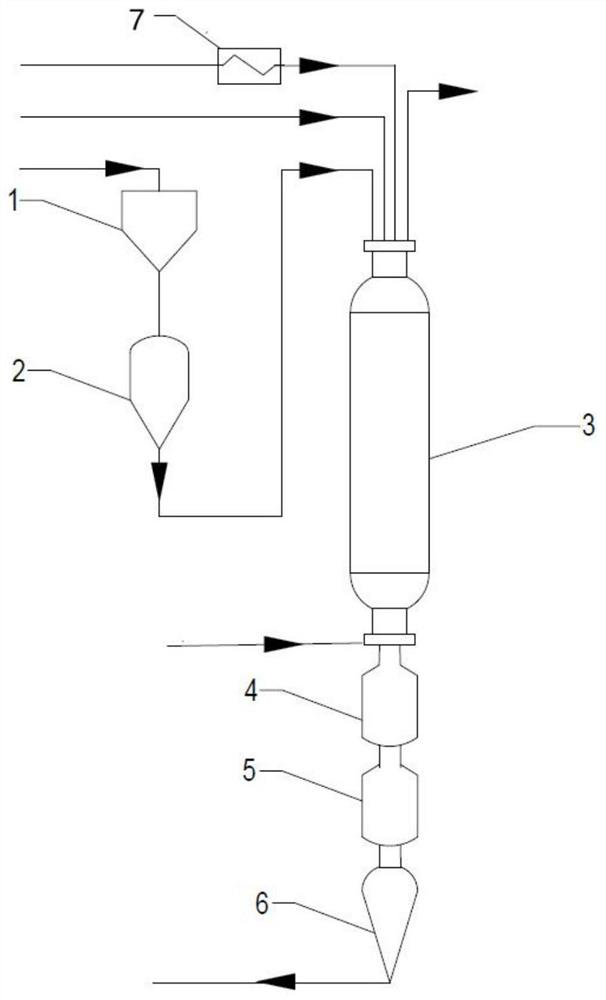

Image

Examples

Embodiment 1

[0037] Embodiment one: the conveying device is a screw conveyor;

Embodiment 2

[0038] Embodiment 2: The conveying device is a pneumatic conveying system.

[0039] In the embodiment of the present invention, the melting furnace 4 is a tank reactor,

[0040] Embodiment 1: the shell of the melting furnace 4 adopts a water jacket structure;

[0041] Embodiment 2: the shell of the melting furnace 4 is lined with a refractory lining structure; the lining of the melting furnace 4 can also be other cooling forms to protect the shell;

[0042] The inner wall of the housing of the melting furnace 4 is lined with refractory bricks, which can withstand a high temperature of 1500°C.

[0043] In the embodiment of the present invention, the function of the water bath in the step 3 is to cool the reacted glass eutectic to convert it into a solid phase.

[0044] In the embodiment of the present invention, the function of the slag lock bucket 6 is decompression and slag discharge.

[0045] In the embodiment of the present invention, one end of the pipeline for conveyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com