Corrosive agent and corrosion method for displaying original austenite grain boundary of martensitic stainless steel

A martensitic stainless steel and austenite grain boundary technology, applied in the field of metallographic structure observation, can solve the problems of picric acid poisoning, corrosive agent failure, high service temperature, etc., and achieve simple use steps, easy preparation, and increased sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

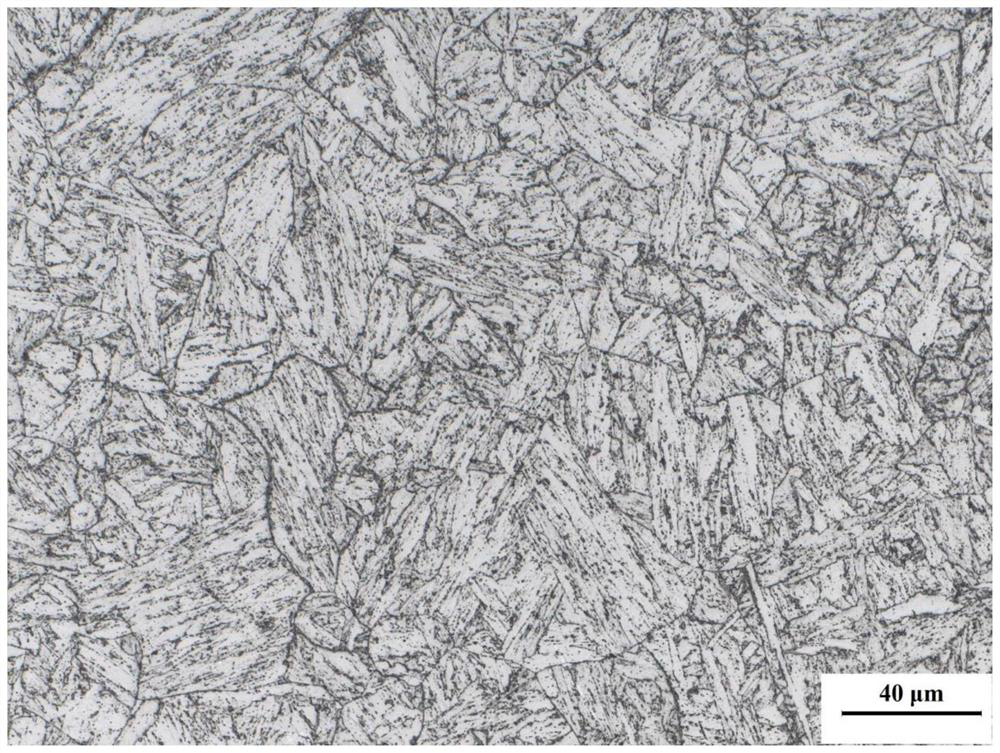

Embodiment 1

[0047] The present invention provides an etchant for displaying the grain boundaries of prior austenite in martensitic stainless steel, which consists of the following components according to the weight ratio: 100ml of saturated alcohol solution of picric acid, 2g of sodium dodecylbenzenesulfonate, HCl solution 3 drops (about 0.15ml), and finally add a small piece of steel about 0.2g; the sample to be corroded is 9Cr0.5Mo1.8WVNb steel (P92 steel) aged at 600°C for 100h.

[0048] Preparation and cleaning steps:

[0049] (1) First, put 9g of picric acid into a flask, add 100ml of absolute ethanol, heat slowly over low heat and stir gently until the crystals are completely dissolved, prepare a saturated picric acid alcohol solution, let it stand for 1 day, and wait for crystals to precipitate Take the supernatant and let it stand for later use.

[0050] (2) Take 100ml of the supernatant of the above-mentioned saturated picric acid alcohol solution after fully standing, add 2g of...

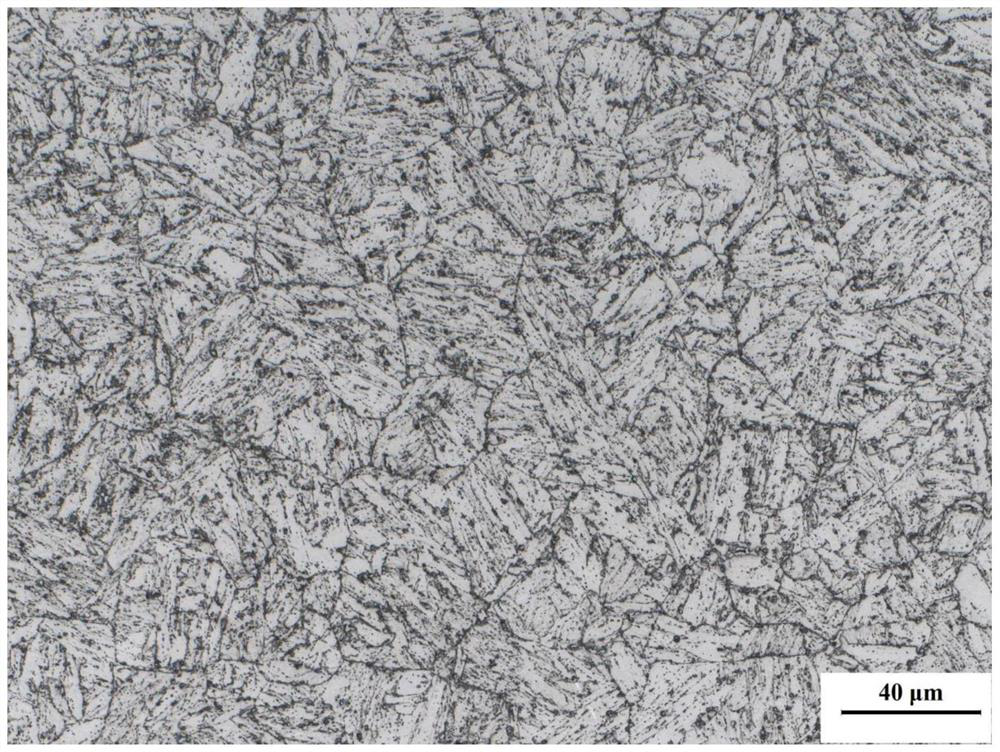

Embodiment 2

[0059] The present invention provides a corrosion agent for displaying the grain boundaries of prior austenite in martensitic stainless steel, which consists of the following components according to the weight ratio: 100ml of saturated alcohol solution of picric acid, 2g of sodium tridecylbenzenesulfonate, HCl solution 5 drops (about 0.25ml), and finally add a small piece of steel about 1g; the sample to be corroded is 9Cr0.5Mo1.8WVNb steel (P92 steel) aged at 600°C for 1000h.

[0060] Preparation and cleaning steps:

[0061] (1) First, put 9g of picric acid into a flask, add 100ml of absolute ethanol, heat slowly over low heat and stir gently until the crystals are completely dissolved, prepare a saturated picric acid alcohol solution, let it stand for 1 day, and wait for crystals to precipitate Take the supernatant and let it stand for later use.

[0062] (2) Take 100ml of the supernatant of the above-mentioned saturated picric acid alcohol solution after fully standing, ad...

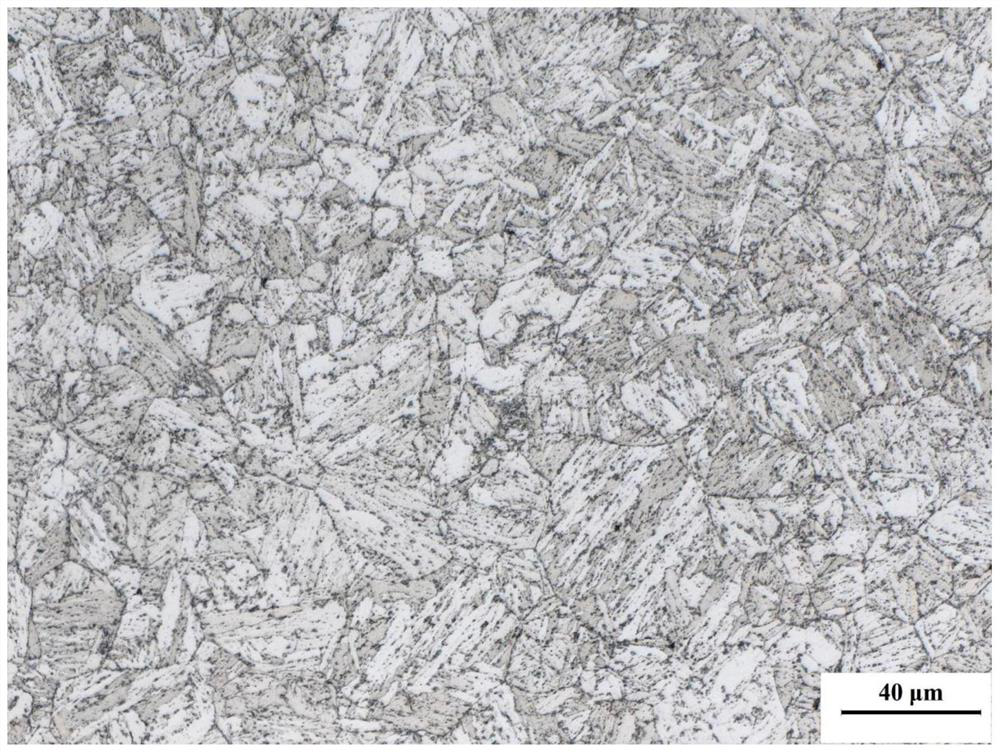

Embodiment 3

[0071] The present invention provides a corrosion agent for displaying the grain boundaries of prior austenite in martensitic stainless steel, which consists of the following components according to the weight ratio: 100ml of saturated alcohol solution of picric acid, 10g of sodium dodecylbenzenesulfonate, and HCl solution 8 drops (about 0.4ml), and finally add a small piece of steel about 2g; the sample to be corroded is 11Cr0.3Mo1.5W1.5CoSiVNb steel (VM12 steel) aged at 600°C for 100 hours.

[0072] Preparation and cleaning steps:

[0073] (1) First, put 9g of picric acid into a flask, add 100ml of absolute ethanol, heat slowly over low heat and stir gently until the crystals are completely dissolved, prepare a saturated picric acid alcohol solution, let it stand for 1 day, and wait for crystals to precipitate Take the supernatant and let it stand for later use.

[0074] (2) Take 100ml of the supernatant of the above-mentioned saturated picric acid alcohol solution after fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com