Powder metallurgy mixed material formula modeling and control method based on multiple regression

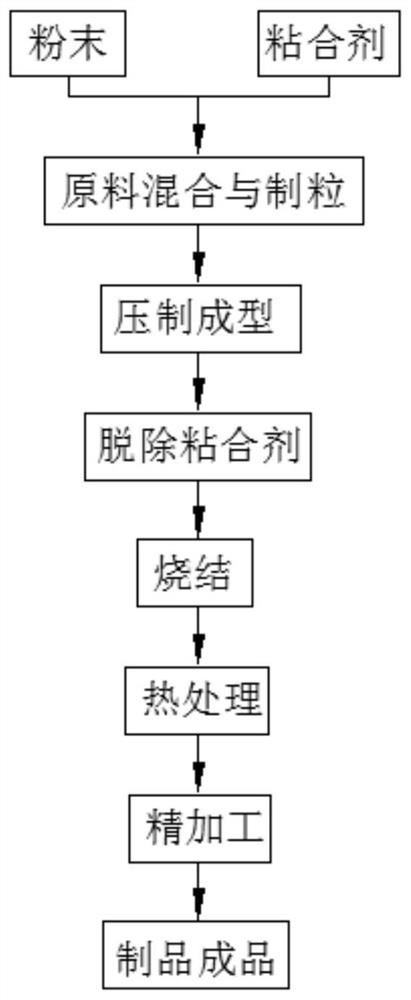

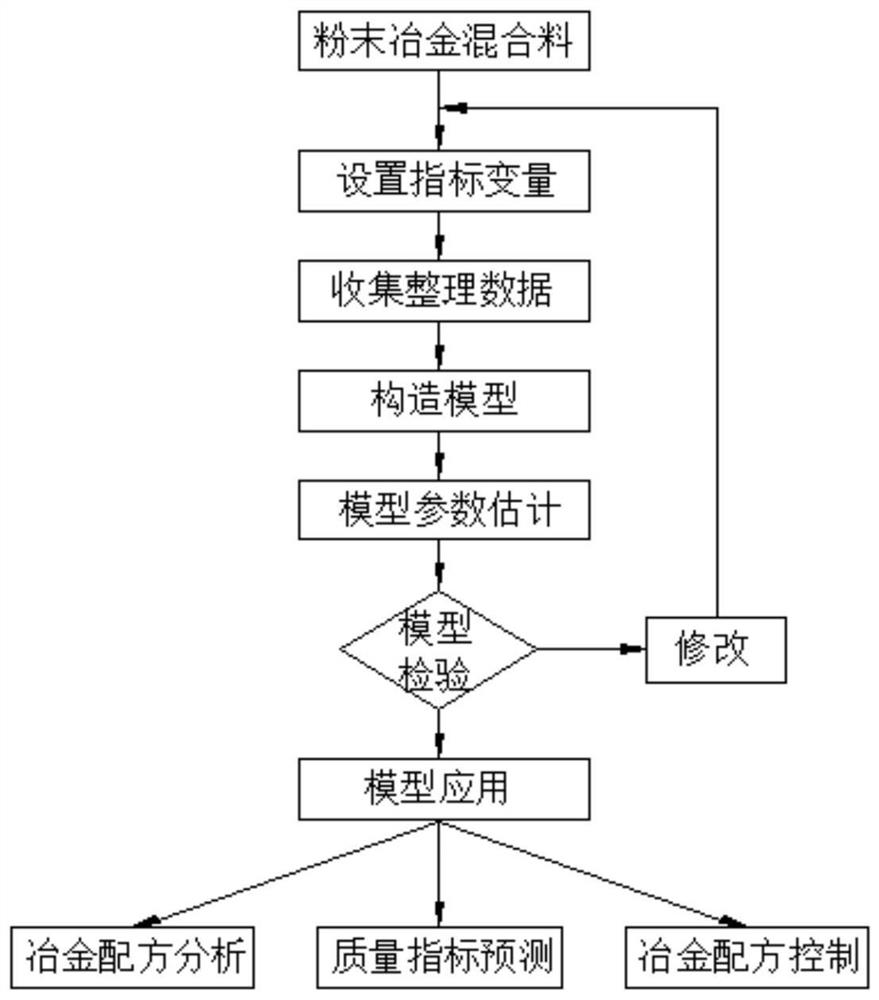

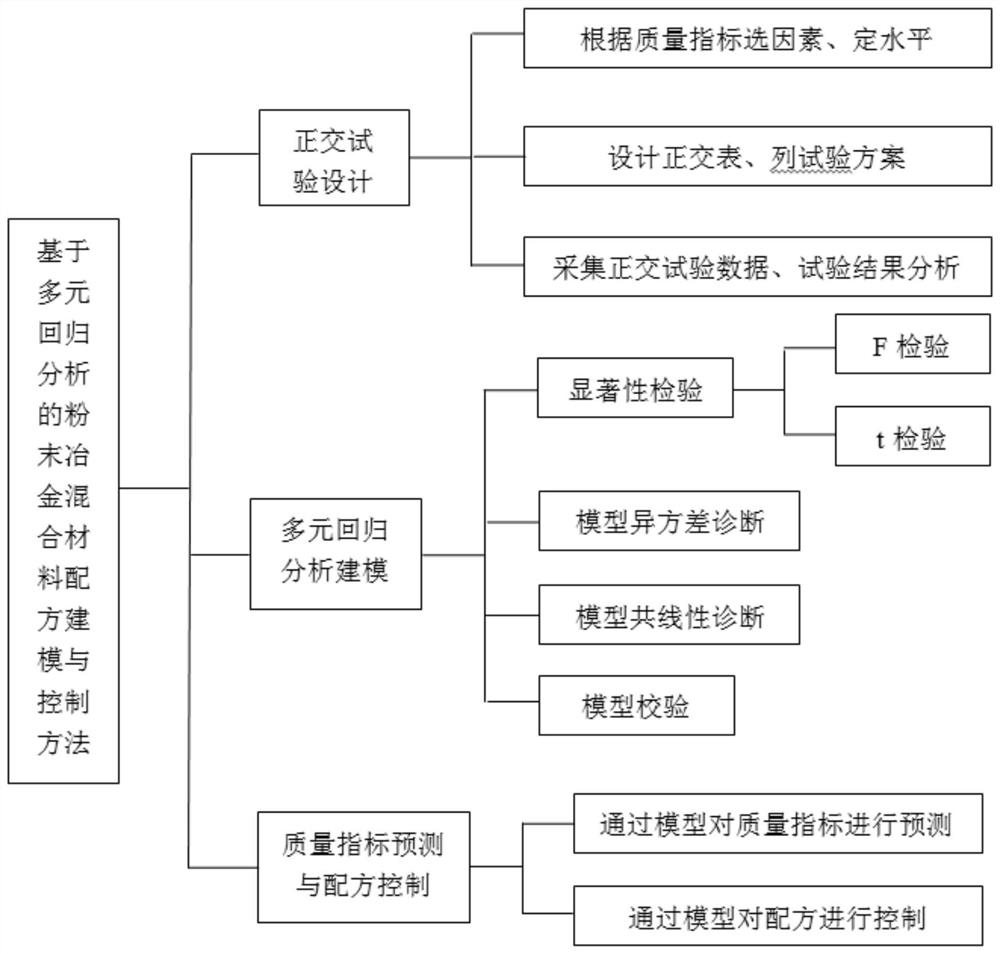

A multiple regression equation and mixed material technology, applied in the field of powder metallurgy mixed material formulation modeling and control based on multiple regression, can solve the problems of long trial production cycle, large power consumption, and time-consuming, so as to reduce the trial production cycle and improve production efficiency , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] This embodiment is an iron-based product, and the product of the sample is an iron-based axle sleeve, and the size is φ20mm×18mm. The purity of the iron powder used in the experiment is 99.9%, and the particle size is 75 μm. In this example, the hardness is the product quality index (dependent variable y), Select two independent variable factors that have a greater impact on the hardness index, namely, the copper mass fraction x 1 and aluminum mass fraction x 2 , other mixtures, such as carbon (C) and zinc stearate mass fraction, all remain unchanged in the formula of the previous process, and the sample is tested by Brinell hardness tester, and each sample is tested at three points, and the result is The average of three points, using L 16 (4 2 ) Orthogonal test table, that is, the orthogonal test has 4 levels and 2 factors, and 16 sample data. The hardness test is carried out on the samples. The results of the orthogonal test are shown in Table 1.

[0085] The orth...

Embodiment 2

[0118] This embodiment is a copper-based product. The product of the sample is a copper-based shaft sleeve with a size of φ22mm×20mm. Adding trace non-metal alloy elements phosphorus (P) and boron (B) to the copper base has obvious alloying effect. It is an important channel to effectively improve the wear resistance of materials at a lower cost. This example considers the influence of phosphorus (P) and boron (B) in copper-based powder metallurgy mixed powder on hardness and wear resistance, and considers the impact of sintering temperature on hardness and wear resistance. The impact of wear resistance, using P content, B content and sintering temperature as the three factors of this experiment, each factor takes 3 levels, the factor level table is shown in Table 7, using L 9 (3 3 ) Orthogonal test table, that is, the orthogonal test has 3 levels and 3 factors, and 9 sample data. The hardness and wear resistance of the samples are tested. The results of the orthogonal test ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com