Peeling machine for fresh broad bean processing

A technology of peeling machine and broad beans, which is applied in the direction of applications, conveyors, conveyor objects, etc., can solve problems affecting the quality of broad beans and broad bean damage, and achieve the effects of facilitating subsequent processing, improving processing efficiency, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

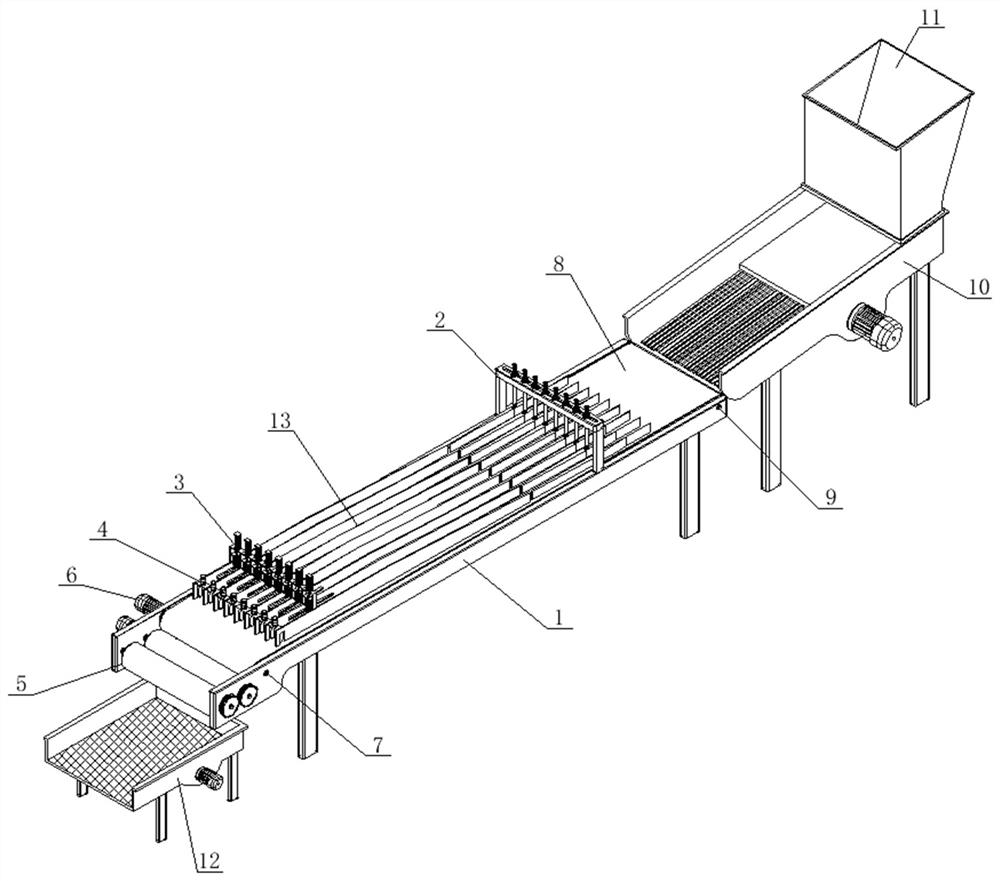

[0040] Such as Figure 1-10 As shown, a fresh broad bean peeling machine includes a body (1), an adjustment mechanism (2), an opening mechanism (3), a straightening mechanism (4) and an extrusion mechanism (5). The rear end of the body (1) is The drive motor (6) is fixedly connected to the left side, and the drive roller (7) is fixedly connected to the end of the main shaft of the drive motor (6). The driven roller (9) is connected in rotation, and the end of the driven roller (9) is connected in rotation with the machine body (1). A vibrating feeder (10) is provided on the upper right side of the machine body (1). The vibrating feeder (10) A storage hopper (11) is provided on the upper side, a vibrating screen (12) is provided at the lower left side of the body (1), and a material guide plate (13) is fixedly connected to the left side of the upper end of the body (1).

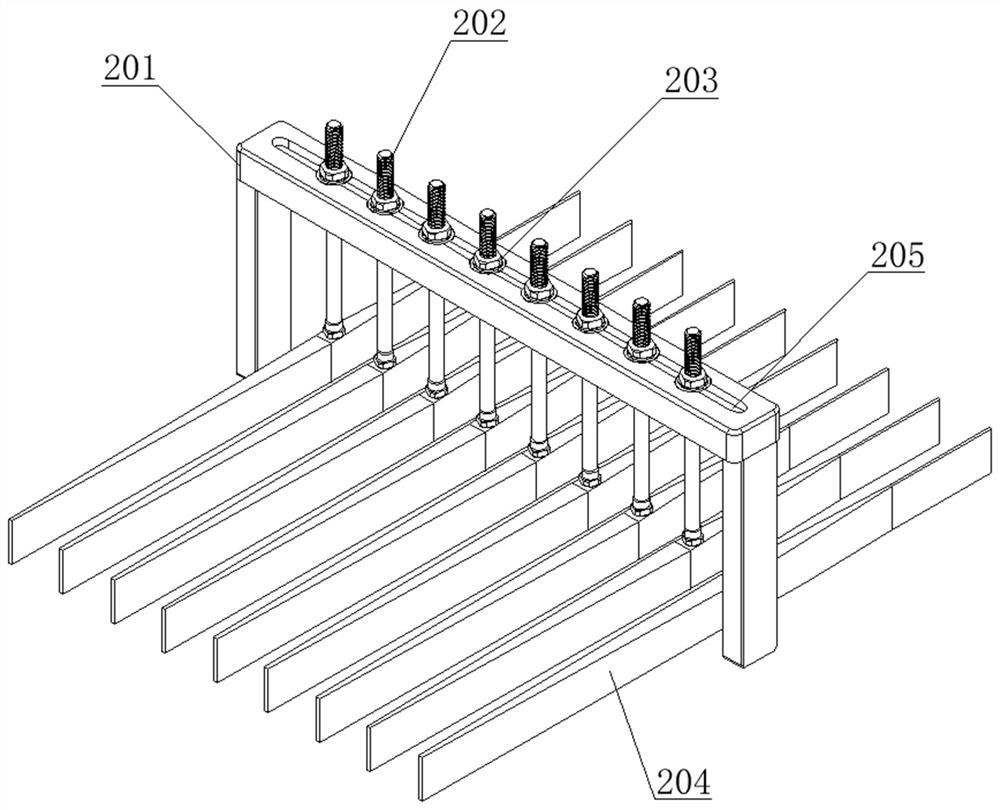

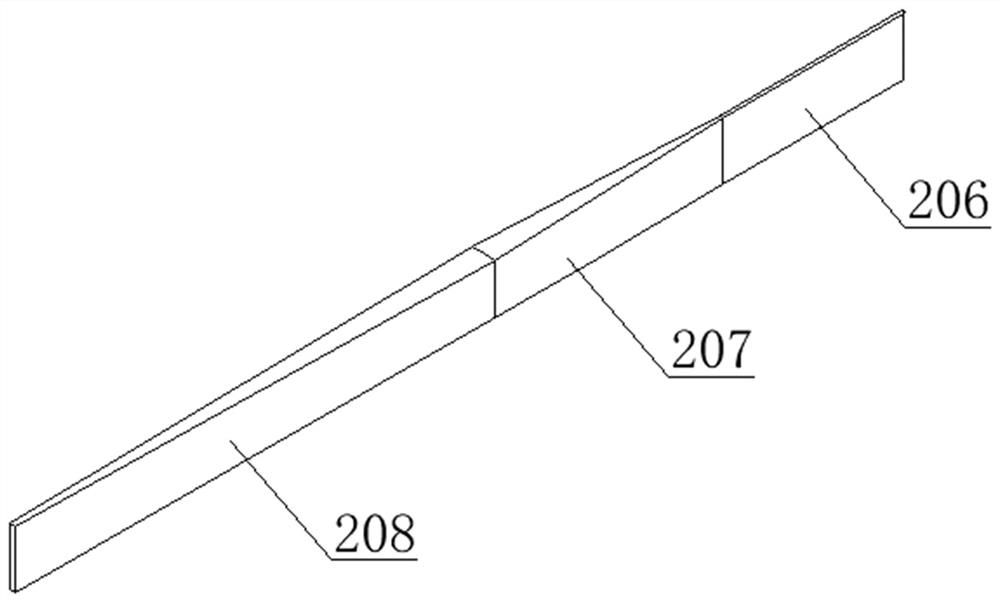

[0041] The right side of the upper end of the body (1) is provided with an adjustment mechanism (2), and t...

Embodiment 2

[0050] Such as Figure 1-10 As shown, a fresh broad bean peeling machine includes a body (1), an adjustment mechanism (2), an opening mechanism (3), a straightening mechanism (4) and an extrusion mechanism (5). The rear end of the body (1) is The drive motor (6) is fixedly connected to the left side, and the drive roller (7) is fixedly connected to the end of the main shaft of the drive motor (6). The driven roller (9) is connected in rotation, and the end of the driven roller (9) is connected in rotation with the machine body (1). A vibrating feeder (10) is provided on the upper right side of the machine body (1). The vibrating feeder (10) A storage hopper (11) is provided on the upper side, a vibrating screen (12) is provided at the lower left side of the body (1), and a material guide plate (13) is fixedly connected to the left side of the upper end of the body (1).

[0051] The right side of the upper end of the body (1) is provided with an adjustment mechanism (2), and t...

Embodiment 3

[0060] Such as Figure 1-10 As shown, a fresh broad bean peeling machine includes a body (1), an adjustment mechanism (2), an opening mechanism (3), a straightening mechanism (4) and an extrusion mechanism (5). The rear end of the body (1) is The drive motor (6) is fixedly connected to the left side, and the drive roller (7) is fixedly connected to the end of the main shaft of the drive motor (6). The driven roller (9) is rotationally connected, and the end of the driven roller (9) is rotationally connected with the machine body (1). A vibrating feeder (10) is provided on the upper right side of the machine body (1). The vibrating feeder (10) A storage hopper (11) is provided on the upper side, a vibrating screen (12) is provided at the lower left side of the body (1), and a material guide plate (13) is fixedly connected to the left side of the upper end of the body (1).

[0061]The right side of the upper end of the body (1) is provided with an adjustment mechanism (2), and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com