Method for manufacturing Cu-based alloy cladding layer by adopting infrared laser

An infrared laser and base alloy technology, applied in metal material coating process, coating, liquid chemical plating and other directions, can solve the problems of difficult application and popularization, high cost, etc., to achieve good fluidity, low energy consumption, The effect of high electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

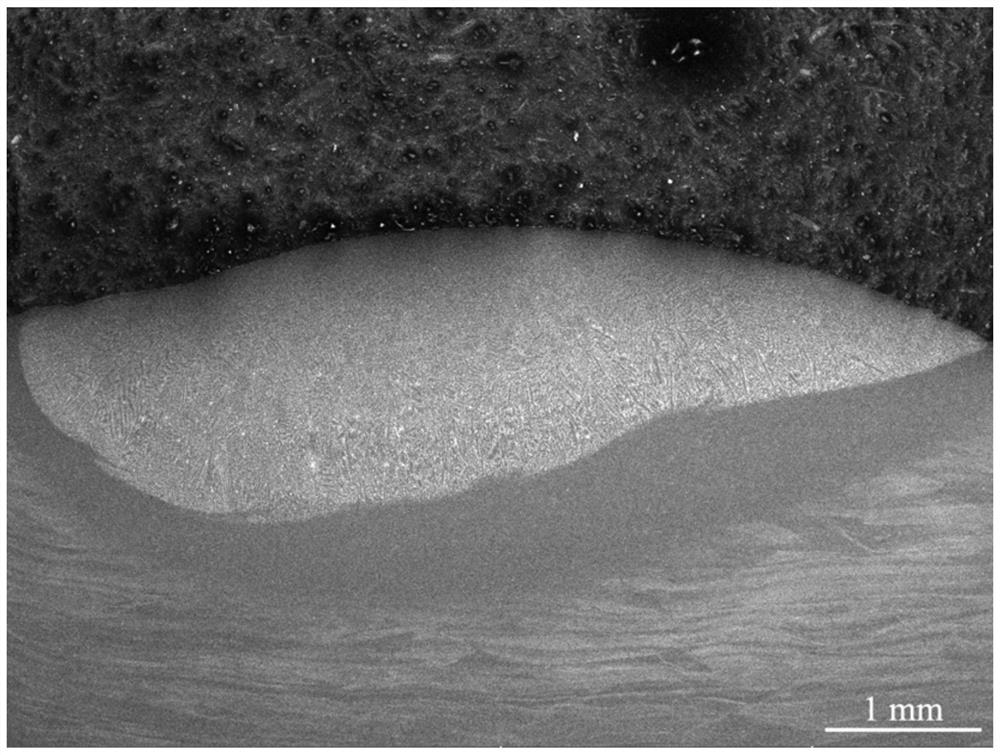

[0048] The following is attached Figure 1-4 The application is described in further detail.

[0049] The embodiment of the present application discloses a method for manufacturing a Cu-based alloy cladding layer by using an infrared laser.

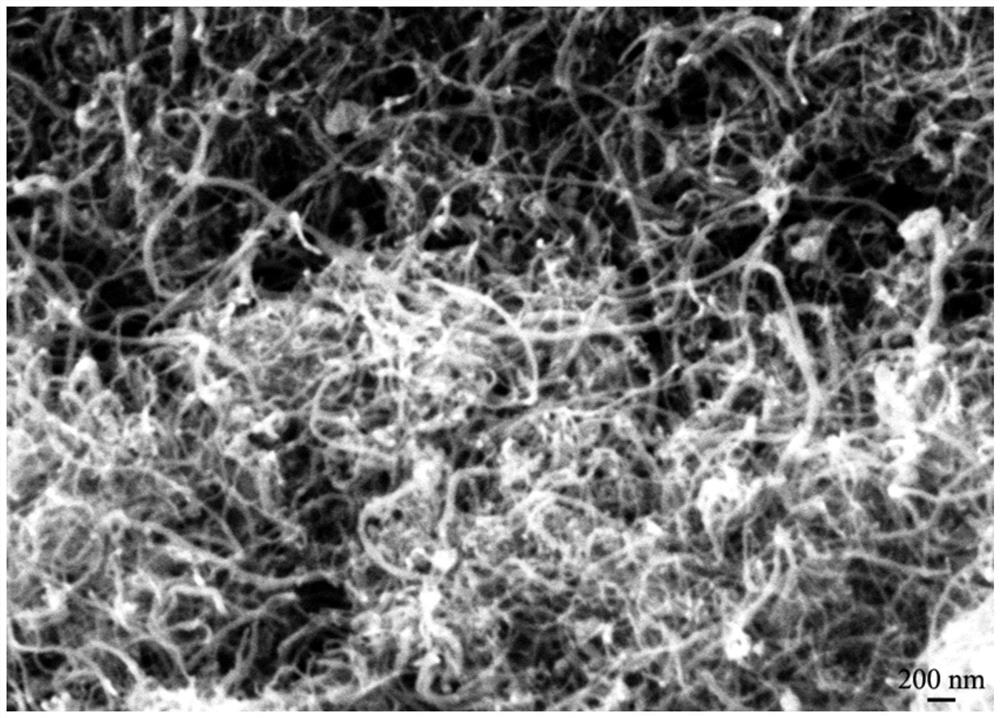

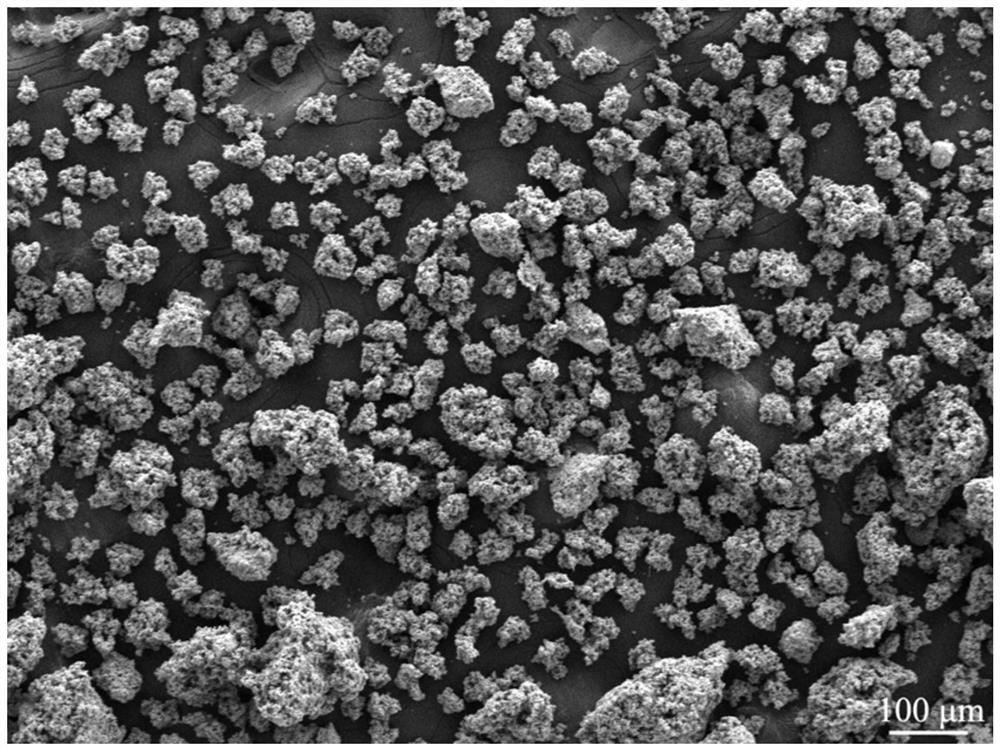

[0050] S1: Select two 20mL plastic centrifuge tubes, and weigh 0.1 gram of multi-walled carbon nanotubes in each tube (the carbon nanotubes in the embodiment are prepared by chemical catalysis, with a microscopic outer diameter of 30-50nm and an average length of about 10 μm); add about 10 mL of 68% nitric acid to each centrifuge tube to immerse the carbon nanotubes, cover the tube cap and let it stand for 24 hours, then centrifuge, pour out the nitric acid, and then replace it with about 10 mL of 40% hydrofluoric acid The acid was submerged again, and after standing for 24 hours, it was centrifuged again, and the hydrofluoric acid was poured out, and deionized water was added several times for cleaning.

[0051] S2: Take two 100mL beak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com