ECTFE and FRP composite board

A composite plate and plate technology, applied in synthetic resin layered products, layered products, glass/slag layered products, etc., can solve the problems of uneconomical structural materials, poor molding processability, poor mechanical properties, etc., and achieve excellent Effect of chemical resistance, mature molding process, low water vapour permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

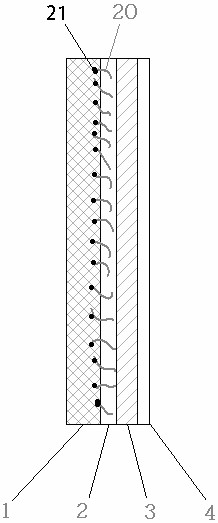

[0017] Such as figure 1 The shown ECTFE / FRP composite sheet forms a four-layer composite structural sheet of ECTFE layer (including fiber insertion layer), fiber bonding layer, FRP layer, and gel coat layer.

[0018] The implanted fiber is a polymer fiber with a melting point higher than the melting point of ECTFE. One end of the high-melting point polymer fiber is first subjected to heat shrinkage treatment by local heating higher than the respective melting point, so that the diameter of the fiber at this end becomes larger and thicker, and then inserted into the molten ECTFE surface and condensation anchored in it.

[0019] The thickness of the ECTFE sheet is 1-3mm, the thickness of the fiber insertion layer is 0.5-1mm, the thickness of the fiber bonding layer is 0.5-2mm, and the thickness of the FRP layer is 2-10mm.

Embodiment 2

[0021] An ECTFE / FRP composite board forms a three-layer composite structural board of an ECTFE layer, a fiber insertion layer, a fiber bonding layer+FRP layer.

[0022] The implanted fiber is a glass fiber with a melting point higher than the melting point of ECTFE. One end of the glass fiber is first subjected to heat-shrinkage treatment by high-temperature local heating, so that the diameter of the fiber at this end becomes larger and thicker, and then inserted into the surface of the molten ECTFE and condensed and anchored in it .

[0023] The resin matrix in the fiber bonding layer is basically the same as the matrix material of FRP.

[0024] The thickness of the ECTFE sheet is 2-3mm, the thickness of the fiber insertion layer is 0.5-1mm, and the thickness of the fiber bonding layer and the thickness of the FRP layer together form a thicker FRP layer with similar composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com