A kind of self-healing polyurethane based on boroxane and preparation method thereof

A self-healing, polyurethane technology, applied in the field of material science, can solve problems such as complex synthesis routes and processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

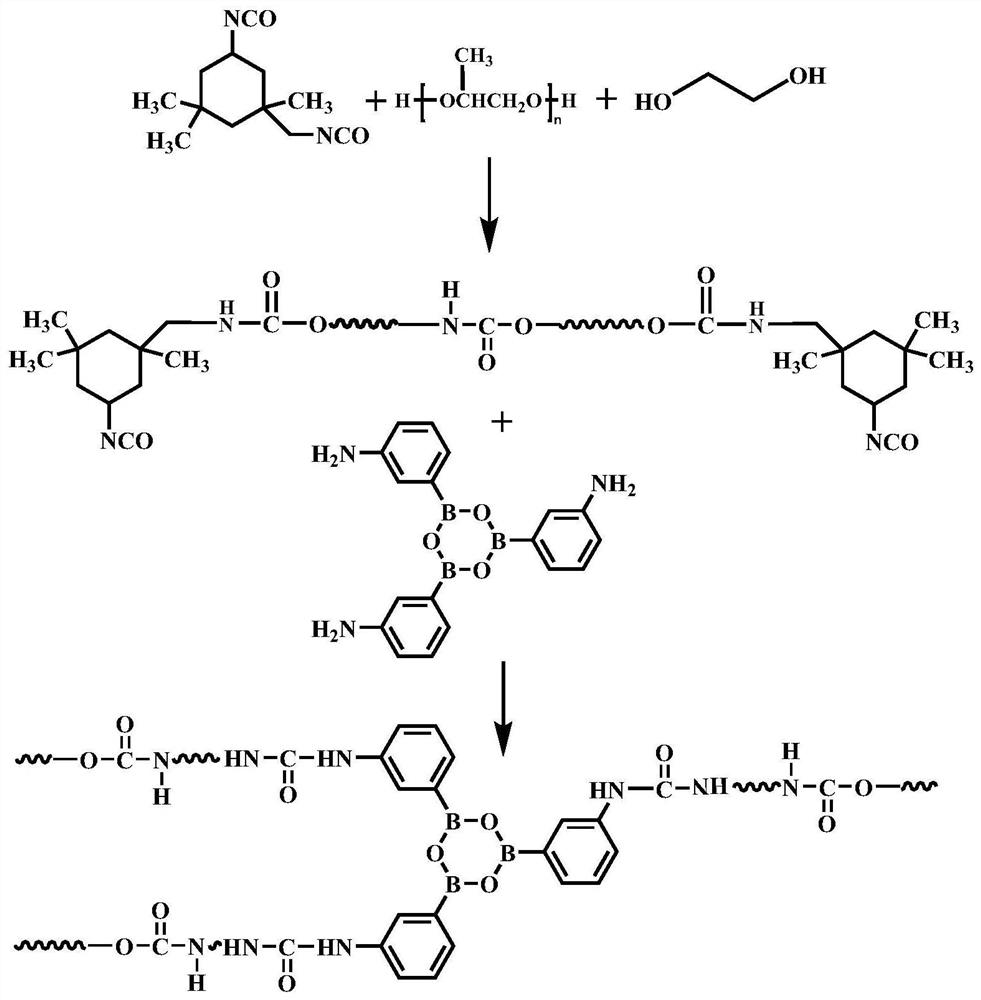

[0040] A kind of preparation method of the self-healing type polyurethane of boroxane, comprises the following steps, and the synthetic route is such as figure 1 shown,

[0041] Step 1: NH 2 - Preparation of Boroxine

[0042] Weigh 3 mmol of 3-aminophenylboronic acid as the solute, take toluene as the solvent, the concentration of 3-aminophenylboronic acid is 0.01644g / ml during mixing, react at 80 ° C for 12 h, after the reaction is completed, suction filtration, and vacuum drying at 60 ° C to obtain Boroxane-containing crosslinking agent NH 2 -Boroxine.

[0043] Preparation of isocyanate-based polyurethane prepolymer:

[0044] Add 20 mmol of isophorone diisocyanate, 10 mmol of polypropylene glycol (PPG2000), and 1.3 mmol of small molecule chain extender 1,4-butanediol into a three-necked flask equipped with a stirrer and a glass stopper, mix well, Under a nitrogen atmosphere, it is heated with a collector-type constant temperature heating magnetic stirrer (oil bath), and...

Embodiment 2

[0050] A preparation method of a self-healing polyurethane of boroxane, comprising the following steps:

[0051] Step 1: NH 2 - Preparation of Boroxine

[0052] Weigh 6 mmol of 3-aminophenylboronic acid as the solute, take toluene as the solvent, the concentration of 3-aminophenylboronic acid is 0.01600g / ml during mixing, react at 85°C for 13h, filter with suction after the reaction, and vacuum dry at 60°C to obtain boroxane-containing product NH 2 -Boroxine.

[0053] Preparation of Isocyanate-Based Polyurethane Prepolymers

[0054] Add 20 mmol of isophorone diisocyanate, 10 mmol of polypropylene glycol (PPG2000), and 1.4 mmol of small molecule chain extender 1,4-butanediol into a three-necked flask equipped with a stirrer and a glass stopper, and mix well. Under a nitrogen atmosphere, use a collector-type constant temperature heating magnetic stirrer to heat (oil bath), and then heat up to 70° C. for 4 hours to obtain PPU.

[0055] Step 2: Based on NH 2 - Preparation of s...

Embodiment 3

[0060] A preparation method of a self-healing polyurethane of boroxane, comprising the following steps:

[0061] Step 1: NH 2 - Preparation of Boroxine

[0062] Weigh 9 mmol of 3-aminophenylboronic acid as the solute, take toluene as the solvent, the concentration of 3-aminophenylboronic acid is 0.01820g / ml during mixing, react at 80°C for 13h, filter with suction after the reaction, and vacuum dry at 60°C to obtain boroxane-containing product NH 2 -Boroxine.

[0063] Preparation of isocyanate-based polyurethane prepolymer:

[0064] Add 30 mmol of isophorone diisocyanate, 10 mmol of polypropylene glycol (PPG2000), and 1.5 mmol of small molecule chain extender 1,4-butanediol into a three-necked flask equipped with a stirrer and a glass stopper, and mix well. Under a nitrogen atmosphere, use a collector-type constant temperature heating magnetic stirrer to heat (oil bath), and then heat up to 70° C. for 4 hours to obtain PPU.

[0065] Step 2: Based on NH 2 - Preparation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com