Azobenzene-polyarylene ether nitrile composite material and preparation method thereof

A polyarylether nitrile and composite material technology, which is applied in the field of high-performance organic polymer materials, can solve problems such as photoactive polyarylether nitrile that have not yet appeared, and achieve the effect of easy industrial production and promotion, and stable polymerization molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

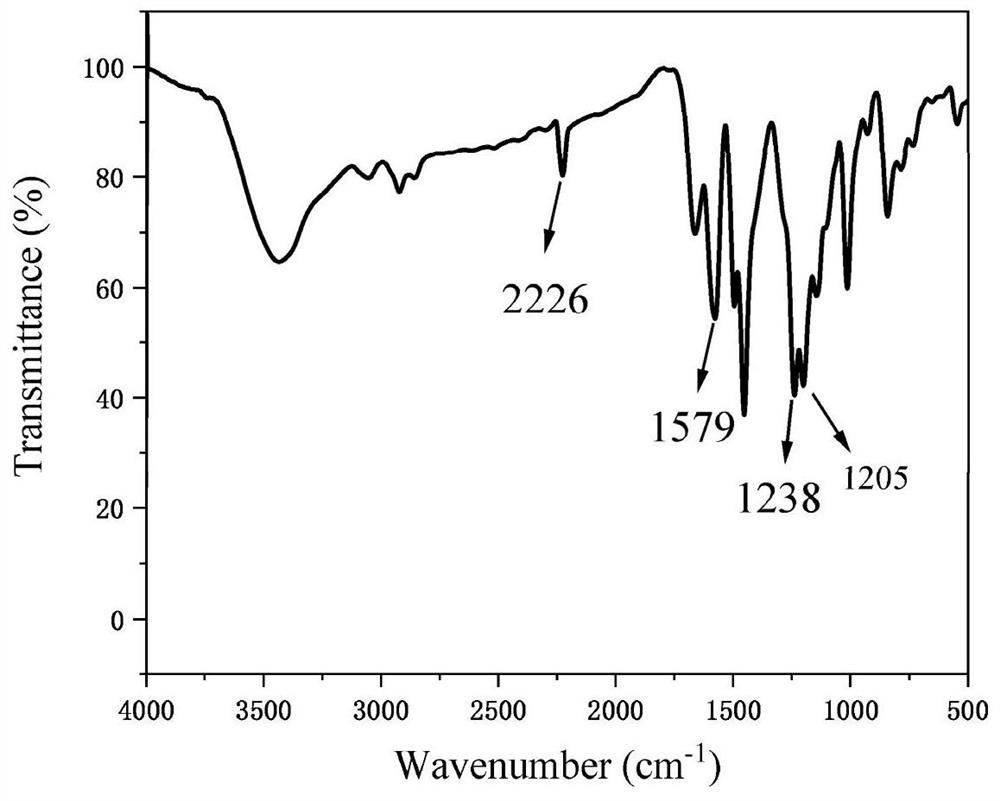

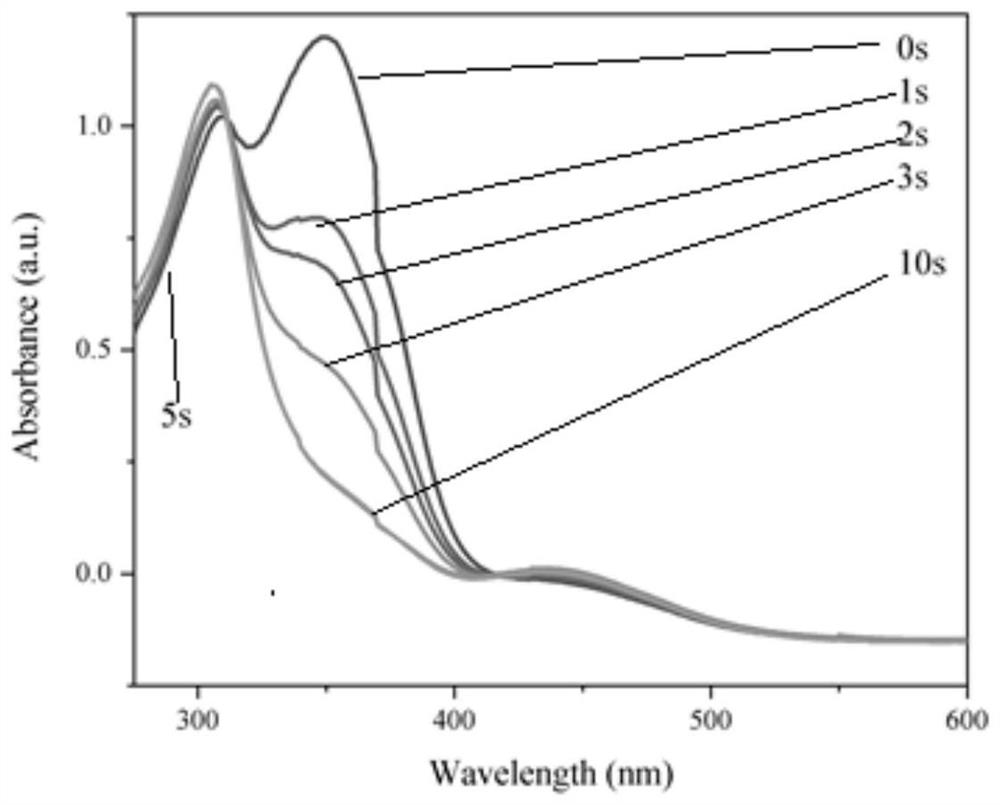

[0030] This embodiment provides a kind of preparation method of azobenzene-polyarylether nitrile composite material, comprising the following steps:

[0031] (1) Add 200 parts by weight (all parts below are parts by weight) of 4,4'-dihydroxyazobenzene, 0.234 parts of 4-hydroxyazobenzene, and 11.172 parts of bisphenol to the reactor in sequence A, 171 parts of 2,6-dichlorobenzonitrile, 138 parts of potassium carbonate, 1500 parts of N-methylpyrrolidone and 200 parts of toluene, mechanically stirred at 300r / min;

[0032] (2) Keep mechanical stirring, control the system temperature at about 115°C, react with water for 2 hours, then gradually increase the temperature to about 180°C within 1 hour, and continue to react for 2 hours;

[0033] (3) Cool the reaction system to 40°C, add 200 parts of N-methylpyrrolidone, stir and dilute the reaction system, then pour it into cold water for precipitation to obtain a crude polymer product;

[0034] (4) Crushing the crude polymer product i...

Embodiment 2

[0036] This embodiment provides a kind of preparation method of azobenzene-polyarylether nitrile composite material, comprising the following steps:

[0037](1) Add 107.5 parts of 4-(4-nitrophenylazo)resorcinol, 2.853 parts of 4-hydroxy-4 nitroazobenzene, and 81.506 parts of tert-butylhydroquinone to the reactor in sequence 187 parts of 3-amino-2,6-dichlorobenzonitrile, 105 parts of sodium carbonate, 800 parts of N,N-dimethylformamide and 300 parts of xylene, mechanically stirred at 300r / min;

[0038] (2) Keep mechanical stirring, control the temperature of the system at about 140°C, react with water for 1.5h, then gradually increase the temperature to about 155°C within 0.5h, and continue the reaction for 3h;

[0039] (3) Cool the reaction system to 70°C, add 300 parts of N,N dimethylformamide, stir and dilute the reaction system, then pour it into cold water for precipitation to obtain a crude polymer product;

[0040] (4) Crushing the crude polymer product into a fine powd...

Embodiment 3

[0042] This embodiment provides a kind of preparation method of azobenzene-polyarylether nitrile composite material, comprising the following steps:

[0043] (1) Add 300.2 parts of 4-[(2,4-dihydroxyphenyl)azo]benzenesulfonate sodium, 16.464 parts by weight of hexafluorobisphenol A, 2.54 parts of 4-(4-butane) to the reactor in sequence phenylazo) phenol, 250 parts of 4-bromo-2,6-dichlorobenzonitrile, 200 parts of potassium bicarbonate, 2000 parts of dimethyl sulfoxide and 400 parts of chlorobenzene, 400r / min mechanical Stir well;

[0044] (2) Keep mechanical stirring, control the temperature of the system at about 135°C, react with water for 4 hours, then gradually increase the temperature to about 190°C within 1.5 hours, and continue the reaction for 3 hours;

[0045] (3) Cool the reaction system to 60°C, add 500 parts of dimethyl sulfoxide, stir and dilute the reaction system, pour it into cold water for precipitation to obtain a crude polymer product;

[0046] (4) Crushing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com