Composition for preventing scar adhesion, postoperative anti-adhesion material and application

A composition and anti-adhesion technology, applied in the field of biomedicine, can solve the problems of unsatisfactory anti-adhesion effect, poor pressure resistance, and short drug retention time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

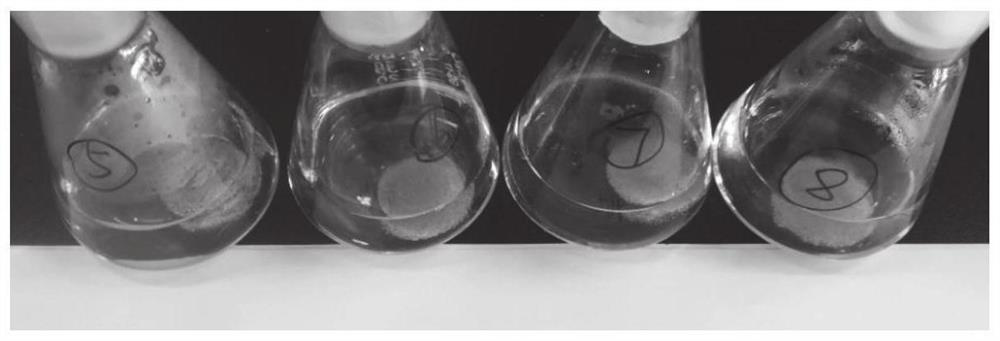

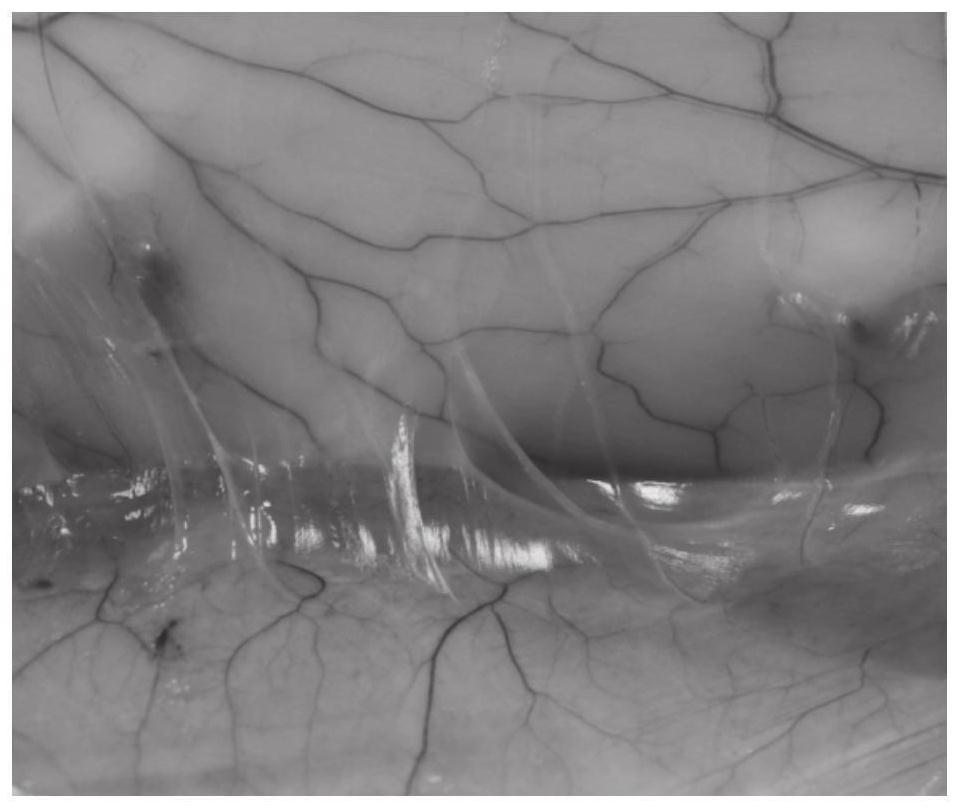

Image

Examples

Embodiment 1

[0044] In this embodiment, a mitomycin C-IFNγ-sodium hyaluronate conjugate is provided, wherein the molecular weight of sodium hyaluronate is 5kDa, and the mitomycin C-IFNγ-sodium hyaluronate conjugate The preparation method is as follows:

[0045] Sodium hyaluronate was dissolved in PBS buffer solution with pH 6.5, after adding an appropriate amount of EDC, stirred at a low speed for 30 minutes at room temperature to activate the carboxyl group of sodium hyaluronate. Dissolve mitomycin C and IFNγ in PBS buffer, slowly add into the activated sodium hyaluronate under stirring condition, after the dropwise addition is completed, stir at room temperature for 8 hours, and dialyze the above-mentioned combination to PBS The product was purified and the purified product was lyophilized for use.

Embodiment 2

[0047] In this embodiment, a mitomycin C-IFNγ-sodium hyaluronate conjugate is provided, wherein the molecular weight of sodium hyaluronate is 10kDa, and the mitomycin C-IFNγ-sodium hyaluronate conjugate The preparation method is as follows:

[0048] Sodium hyaluronate was dissolved in PBS buffer solution with pH 6.0, after adding an appropriate amount of EDC, stirred at a low speed for 35 minutes at room temperature to activate the carboxyl group of sodium hyaluronate. Mitomycin C and IFNγ were dissolved in PBS buffer, slowly added to the activated sodium hyaluronate under stirring conditions, after the addition was completed, stirred at room temperature for 10 hours, and the silk was obtained by column chromatography elution. Split mycin C-IFNγ-sodium hyaluronate conjugate, the purified product is lyophilized for use.

Embodiment 3

[0050] In this embodiment, a mitomycin C-IFNγ-sodium hyaluronate conjugate is provided, wherein the molecular weight of sodium hyaluronate is 10kDa, and the mitomycin C-IFNγ-sodium hyaluronate conjugate The preparation method is as follows:

[0051] Dissolve sodium hyaluronate in PBS buffer at pH 6.0, add appropriate amount of EDC and stir at low speed for 25in at room temperature to activate the carboxyl group of sodium hyaluronate. Mitomycin C and IFNγ were dissolved in PBS buffer, slowly added to the activated sodium hyaluronate under stirring conditions, after the addition was completed, stirred at room temperature for 10 hours, and the silk was obtained by column chromatography elution. Split mycin C-IFNγ-sodium hyaluronate conjugate, the purified product is lyophilized for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com