Production system of bamboo pulp bleached instant paper

A production system and instant technology, applied in the field of papermaking, can solve the problems of low efficiency of manual cutting of roll paper, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

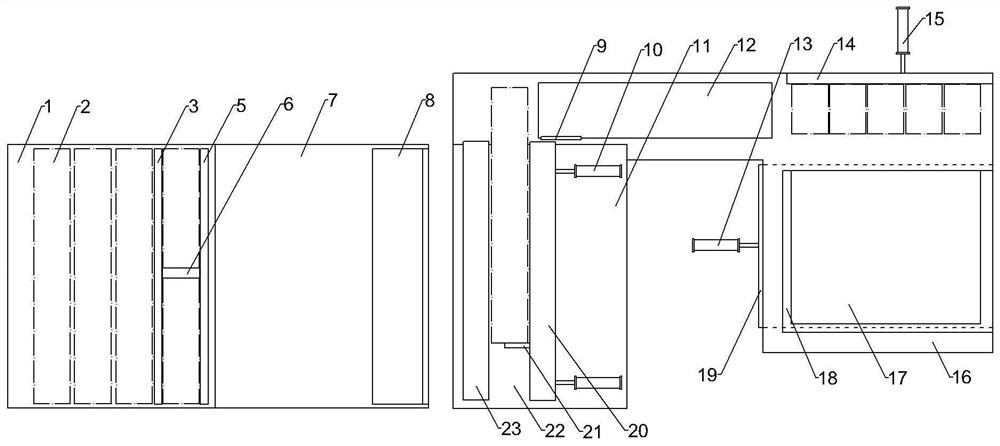

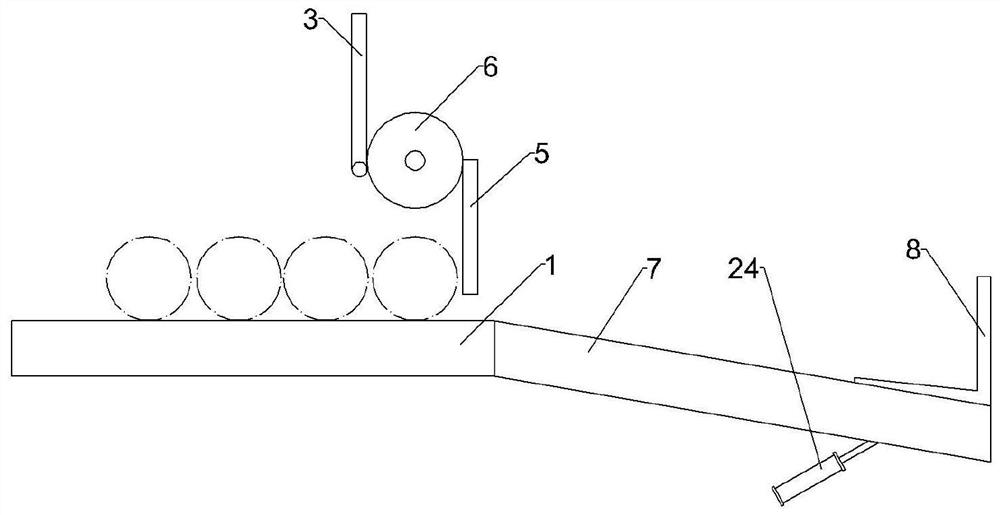

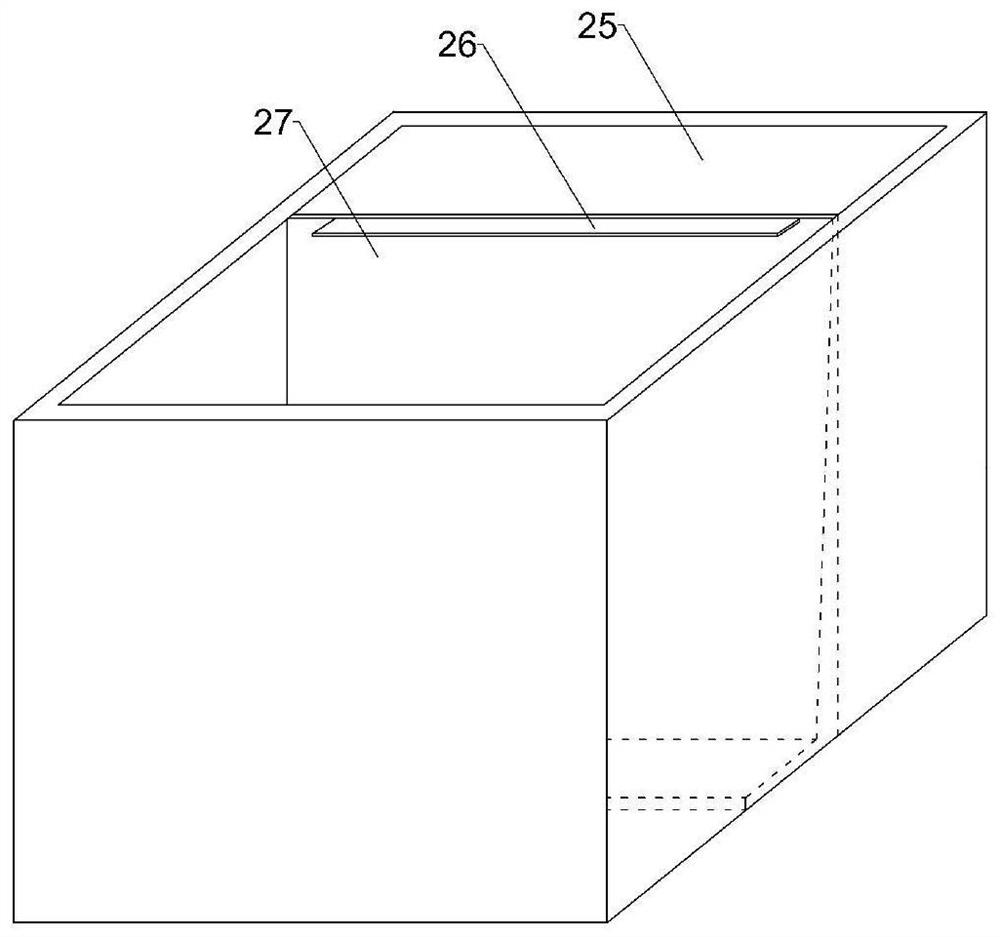

[0025] Such as figure 1 and figure 2 Shown, the production system of bamboo pulp bleached instant paper comprises frame, feeding mechanism, cutting mechanism, boxing mechanism and packaging mechanism, and packaging mechanism adopts the packaging mechanism of roll paper production in the prior art, and packaging mechanism comprises a feeding mechanism conveyor belt. The feeding mechanism includes a material storage platform 1 and a blanking plate 7 arranged obliquely. The material storage platform 1 is integrally formed on the high end of the blanking plate 7, and the low end of the blanking plate 7 faces the cutting mechanism. A discharge assembly is installed at the junction of the storage platform 1 and the blanking plate 7, and the discharge assembly releases a winding roll 2 at a time. The discharge assembly includes a baffle plate 5 vertically slidably installed above the high end of the blanking plate 7 and a press plate 3 vertically slidably installed above the stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com