High-toughness C/ultrahigh-temperature ceramic composite material and preparation method thereof

A technology of ultra-high temperature ceramics and composite materials, which is applied in the field of preparation of ultra-high temperature ceramic matrix composite materials, can solve problems such as poor toughness, achieve the effect of expanding interlayer spacing and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The first aspect of the present invention provides a method for preparing a high-toughness C / ultra-high temperature ceramic composite material, the preparation method comprising the following steps:

[0024] (1) Provide carbon / carbon matrix;

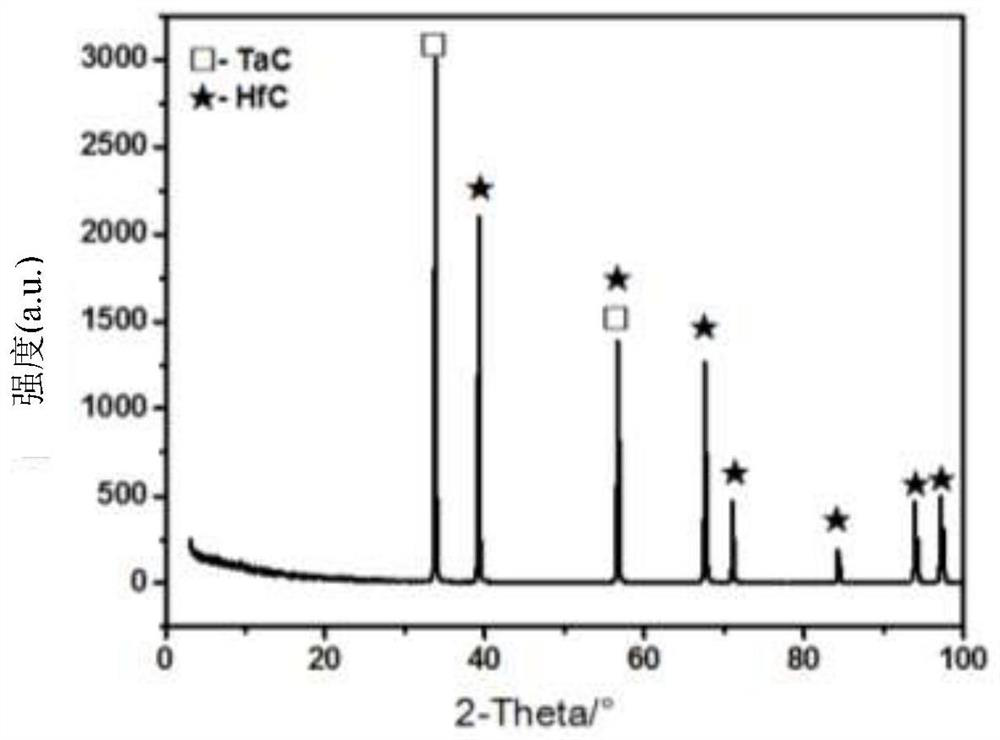

[0025] (2) Under vacuum conditions, ultrasonically mix the expanded boron nitride and the hafnium-tantalum precursor solution to form the expanded boron nitride-modified hafnium-tantalum precursor solution;

[0026] (3) Using the hafnium-tantalum precursor solution modified by the expanded boron nitride as a reactant, react with the carbon / carbon matrix prepared in step (1) by the dipping cracking method to form expanded boron nitride toughened C / C composite material;

[0027] (4) Repeat step (3) at least once to obtain expanded boron nitride toughened C / ultra-high temperature ceramic matrix composite material.

[0028] According to some preferred embodiments, the carbon / carbon matrix is a carbon fiber-reinforced carbon matri...

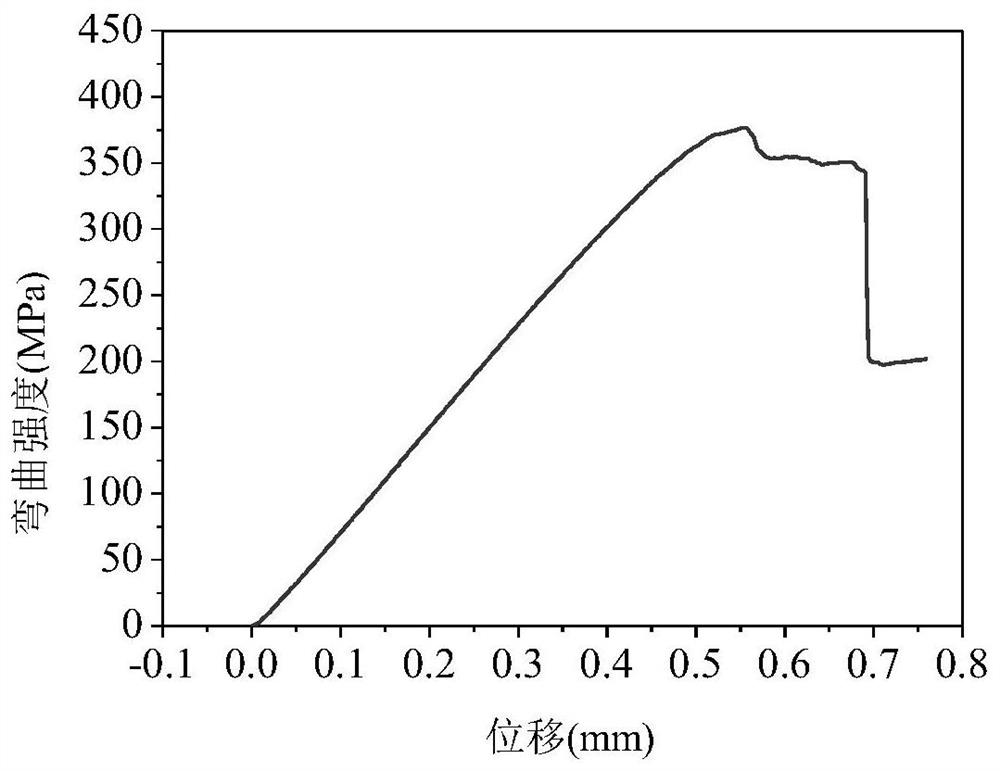

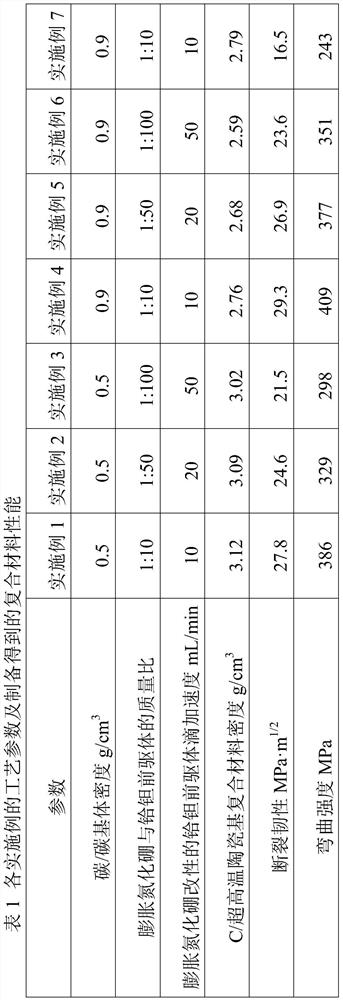

Embodiment 1

[0044] (1) Provide carbon / carbon matrix: provide a density of 0.5g / cm 3 The carbon / carbon matrix is prepared by deposition of carbon matrix on the stitched carbon fiber preform by chemical vapor deposition method.

[0045](2) Expanded boron nitride modified hafnium tantalum precursor solution: disperse boron nitride powder in sodium hydroxide solution (the ratio of boron nitride powder to sodium hydroxide is 1:10, sodium hydroxide The concentration of the solution is 10 g / mL), and placed in a high temperature and high pressure reaction kettle for high temperature and high pressure reaction to obtain expanded boron nitride. Take the above 10.0g expanded boron nitride and place it in a 250mL round bottom flask, add 100.0g hafnium tantalum precursor solution into the long-necked funnel, the mass ratio of expanded boron nitride and hafnium tantalum precursor solution is 1:10, seal the above Round-bottom flask and long-necked funnel, and use a vacuum pump to draw a vacuum. Afte...

Embodiment 2

[0050] (1) Provide carbon / carbon matrix: provide a density of 0.5g / cm 3 The carbon / carbon matrix is prepared by depositing carbon matrix on the stitched carbon fiber preform by chemical vapor deposition process.

[0051] (2) Boron nitride-modified hafnium-tantalum precursor solution: disperse boron nitride powder in sodium hydroxide solution, and place it in a high-temperature and high-pressure reactor for reaction treatment to obtain expanded boron nitride. Take the above 10.0g expanded boron nitride and place it in a 250mL round bottom flask, add 500.0g hafnium tantalum precursor solution into the long-necked funnel, the mass ratio of expanded boron nitride and hafnium tantalum precursor solution is 1:50, seal the above Round-bottom flask and long-necked funnel, and use a vacuum pump to draw a vacuum. After the vacuum in the device reaches 10 Pa and is stable for 5 minutes, slowly drop the hafnium-tantalum precursor solution in the long-necked funnel into the round-bottom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com