A kind of antistatic optical absorption coating with low outgassing rate and preparation method thereof

A technology of optical absorption and outgassing rate, applied in coatings, conductive coatings, chemical industry, etc., can solve the problems of optical system signal intensity reduction, optical system performance attenuation, coating outgassing pollution control, etc. Pollution of sensitive devices, good anti-static performance, and the effect of expanding usage scenarios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

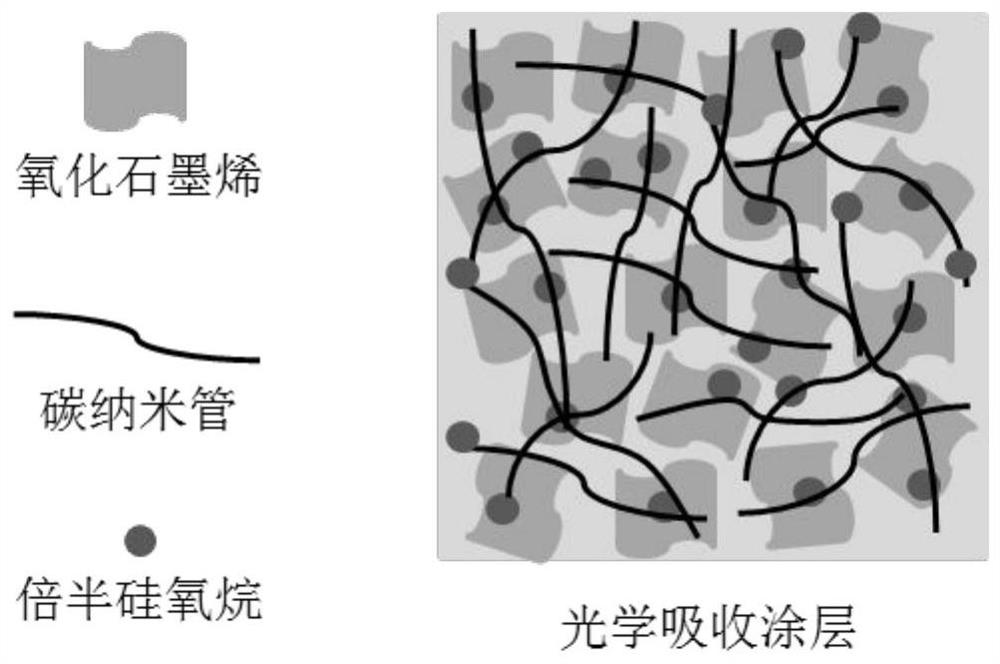

[0035] The preparation process of a low outgassing rate antistatic optical absorption coating is as follows:

[0036] S1: Preparation of Primer Dispersion:

[0037] The graphene oxide microflakes with an average diameter of 10 μm were uniformly dispersed in the organic solvent tetrahydrofuran for ultrasonic treatment, and then a certain amount of cage-type silsesquioxane with an amino side group was added and mixed and stirred at room temperature to obtain graphene oxide / time. Semisiloxane dispersion, wherein the weight ratio of graphene oxide to silsesquioxane is 70:30. The dispersion concentration was 1 mg / ml.

[0038] S2: Preparation of Primer:

[0039] The dispersion liquid prepared in step S1 is uniformly deposited on the clean aluminum base surface, and a primer is obtained by volatilizing an appropriate amount at room temperature, and the volatilization time is 6 hours.

[0040] S3: Preparation of Topcoat Suspension:

[0041] The hydroxylated carbon nanotubes are ul...

Embodiment 2

[0049] An antistatic optical absorption coating with a low outgassing rate, the preparation process of which is as follows:

[0050] S1: Preparation of Primer Dispersion:

[0051]The graphene oxide microflakes with an average diameter of 10 μm are uniformly dispersed in the organic solvent tetrahydrofuran for ultrasonic treatment, and then a certain amount of cage-type silsesquioxane with amino side groups is added and mixed and stirred at room temperature to obtain graphene oxide / sesquioxane A siloxane dispersion, wherein the weight ratio of the graphene oxide to the silsesquioxane is 95:5. The dispersion concentration was 1 mg / ml.

[0052] S2: Preparation of Primer:

[0053] The dispersion liquid prepared in step S1 is evenly deposited on the clean aluminum base surface, and a primer is obtained by volatilizing an appropriate amount at room temperature, and the volatilization time is 6 hours.

[0054] S3: Preparation of Topcoat Suspension:

[0055] The hydroxylated carbo...

Embodiment 3

[0063] An antistatic optical absorption coating with a low outgassing rate, the preparation process of which is as follows:

[0064] S1: Preparation of Primer Dispersion:

[0065] The graphene oxide microflakes with an average diameter of 10 μm are uniformly dispersed in the organic solvent tetrahydrofuran for ultrasonic treatment, and then a certain amount of cage-type silsesquioxane with amino side groups is added and mixed and stirred at room temperature to obtain graphene oxide / sesquioxane Silicone dispersion, wherein the weight ratio of graphene oxide to silsesquioxane is 90:10. The dispersion concentration was 1 mg / ml.

[0066] S2: Preparation of Primer:

[0067] The dispersion liquid prepared in step S1 is evenly deposited on the clean aluminum base surface, and a primer is obtained by volatilizing an appropriate amount at room temperature, and the volatilization time is 6 hours.

[0068] S3: Preparation of Topcoat Suspension:

[0069] The hydroxylated carbon nanotu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com