Multi-layered interlaced membrane and methods for fabrication thereof

A technology of interlaced layers and substrate layers, applied in the direction of textiles and papermaking, non-woven fabrics, layered products, etc., can solve problems such as weak adhesion and easy delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

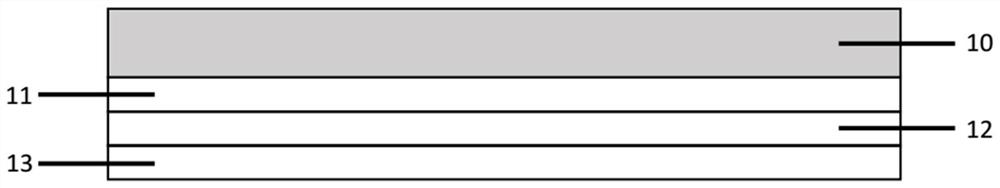

[0041] Synthesis of multilayer interlaced structures

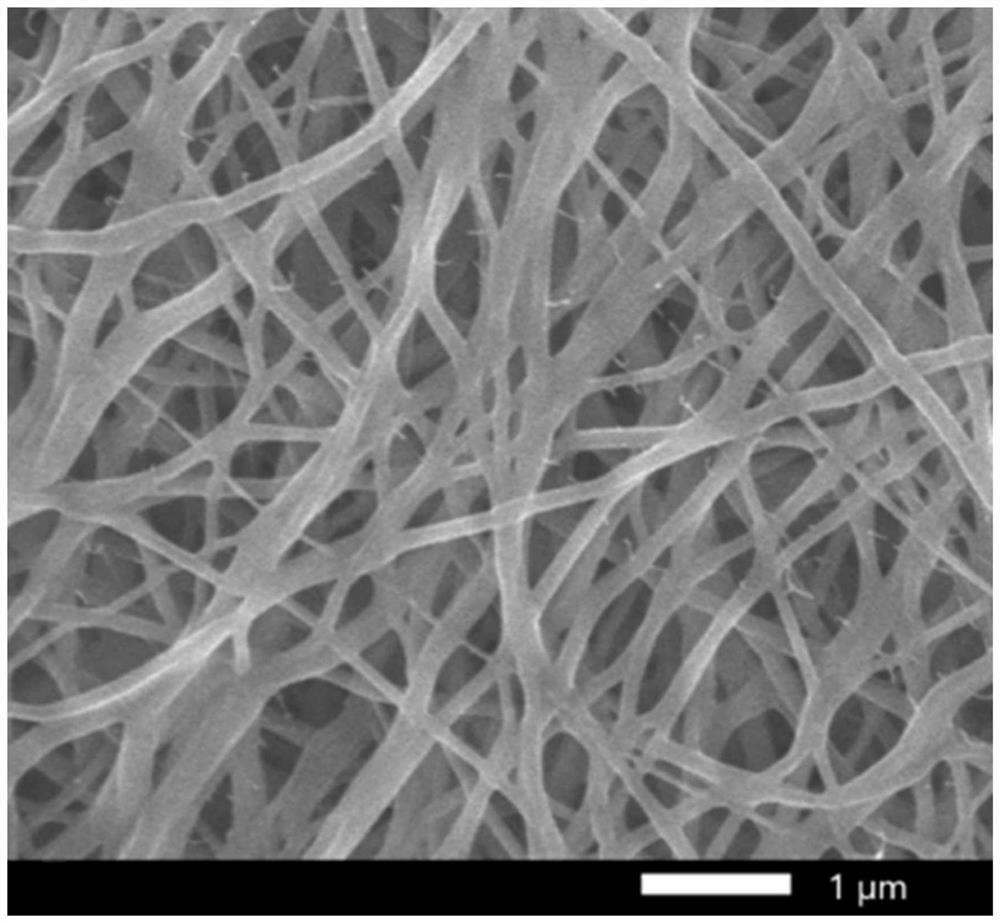

[0042] 17% polystyrene (PS) and 0.1% tetramethylammonium bromide (TEAB) were dissolved in a mixture of dimethylformamide (DMF) and limonene (LMN) (DMF:LMN=1:1.6) to obtain first polymer solution. The first polymer solution was loaded into the needleless electrospinning in the upward rotation direction, wherein the electrospinning of the first polymer solution was performed to form the nanofiber layer 11 under the following conditions: electrode distance: 180 mm; voltage: 50 kV; Metal insert size: 0.6 mm; loading speed: 350 mm / s; air conditions in the spinning chamber: 30% RH and 22°C. Subsequently, 12% PS and 0.15% TEAB were dissolved in a mixture of DMF and LMN (DMF:LMN=1:1.3) to obtain a second polymer solution. The second polymer solution was loaded into the needleless electrospinning in the upward rotation direction, wherein the electrospinning of the second polymer solution was performed to form the interlaced lay...

example 2

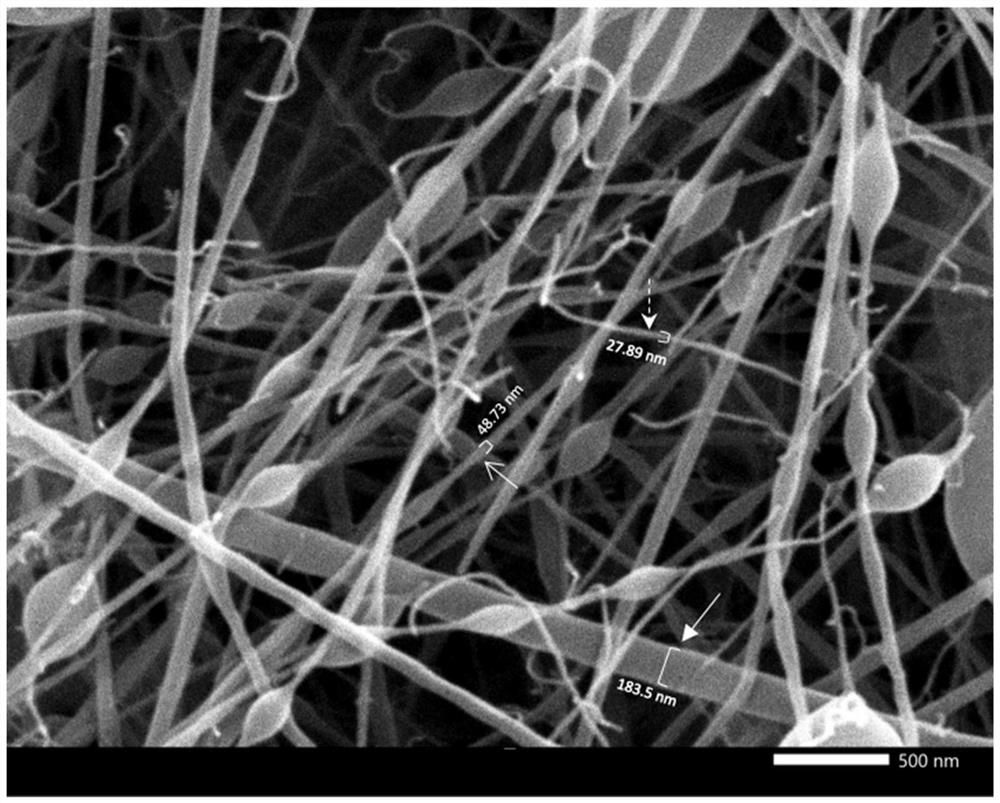

[0063] According to some embodiments of the present invention, 8% polyacrylonitrile (PAN), 0.1% benzyltriethylammonium chloride (BTEAC) are dissolved in DMF to obtain a second polymer solution. The second polymer solution was electrospun in an upward spin direction to form interleaving layers. The diameter of the submicron fibers of the alternating layers is in the range of 180-190nm ( image 3 , arrow); the diameter of the nanofibers of the interlaced layers is in the range of 20-80nm ( image 3 , open arrows); the diameter of the nanobranches of the interlaced layers is in the range of 10-30nm ( image 3 , dotted arrow). In addition, the surface tension of the alternating layers was about 35.2 mN / m.

example 3

[0065] According to some embodiments of the present invention, 8% polyacrylonitrile (PAN), 0.1% benzyltriethylammonium chloride (BTEAC), and 1% L-ascorbic acid are dissolved in DMF to obtain a second polymer solution. The second polymer solution was electrospun in an upward spin direction to form interleaving layers. The diameter of the submicron fibers of the alternating layers is in the range of 140-150nm ( Figure 4 , arrow); the diameter of the nanofibers of the interlaced layers is in the range of 20-90nm ( Figure 4 , open arrows); the diameter of the nanobranches of the interlaced layers is in the range of 10-30nm ( Figure 4 , dotted arrow). In addition, the surface tension of the alternating layers was about 35.2 mN / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com