Preparation method of intercalated graphene blended polyurethane open-cell sponge for adsorption

A technology of intercalated graphite and open-cell sponge, applied in separation methods, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problem of blocking sponge pore structure, unfavorable adsorption performance, uneven distribution of graphene, etc. problem, to achieve the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

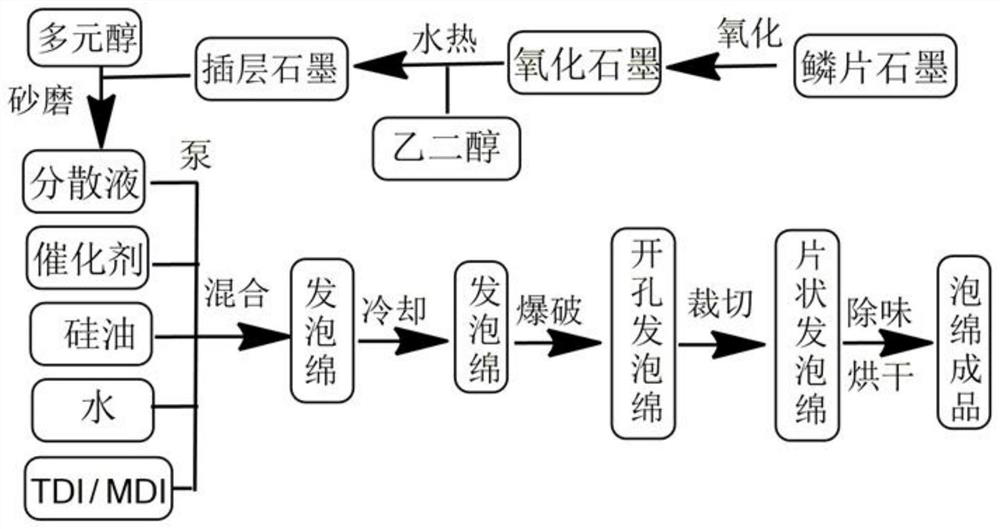

[0032] This embodiment provides the preparation method of intercalated graphene blended polyurethane open-cell sponge, and the preparation process is as follows figure 1 shown.

[0033] S1. Preparation of intercalated graphene nanosheets: Graphene oxide was prepared using the improved Hummers method under ice-water bath conditions. First, prepare 200-mesh flake graphite, sodium nitrate and potassium permanganate with a mass ratio of 1:3:3 , and each sodium nitrate and potassium permanganate are divided into three parts on average, then respectively add sodium nitrate and potassium permanganate three times in the reactor equipped with 200 mesh flake graphite, stir while adding; heat up after stirring for 1h to 90°C, reflux at a constant temperature for 1 hour, and after the solution turns dark brown, centrifuge and wash three times with hydrogen peroxide (30%) and 10% hydrochloric acid respectively to obtain graphene oxide; then add ethylene glycol, and hydrothermally 4h, the ...

Embodiment 2

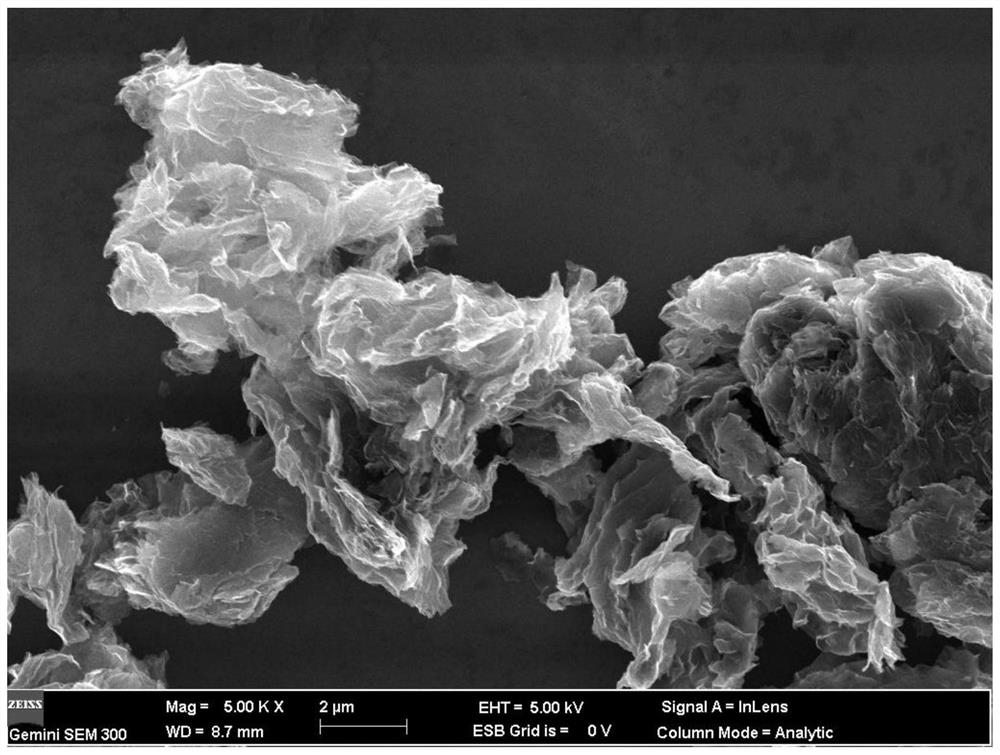

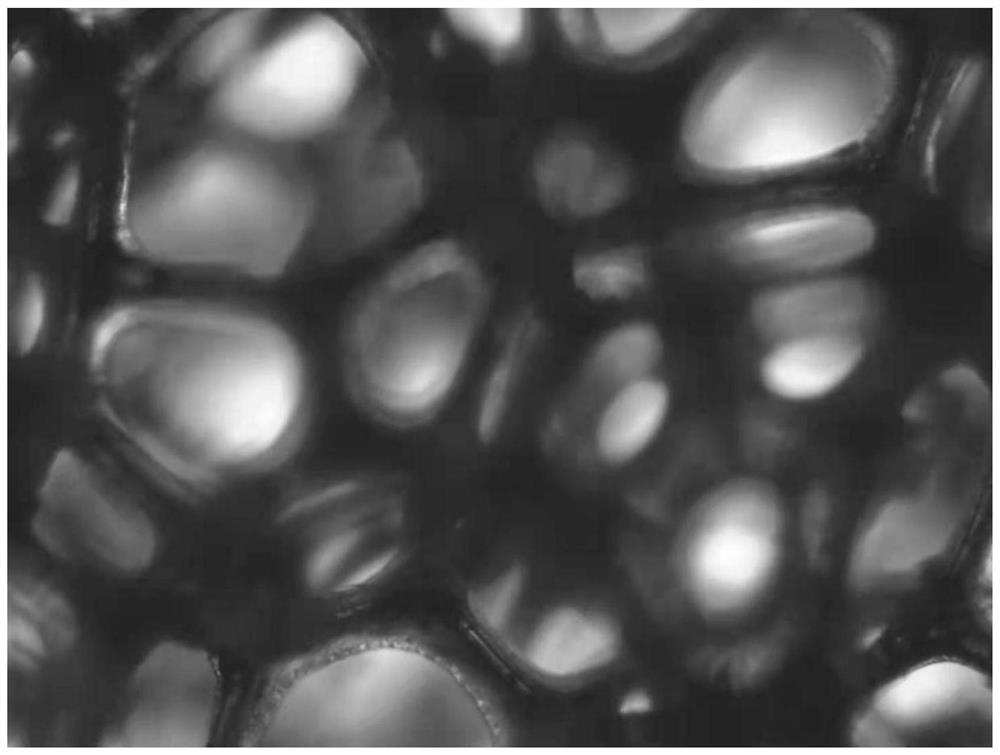

[0042] Substantially the same as in Example 1, but using 1,4-butanediol to intercalate the few-layer graphene oxide nanosheets of graphite, the obtained intercalated few-layer graphene oxide nanosheets have a smaller specific surface, such as Figure 7 , 8 Shown are scanning electron microscopy images of few-layer intercalated graphene and optical microscopy images of the resulting graphene sponge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com