Wet-process magnetic separator and waste catalyst wet-process recovery system

A magnetic separator and wet process technology, applied in the field of wet magnetic separator and waste catalyst wet recovery system, can solve the problems of reducing the recovery rate of magnetic materials, falling off of magnetic materials, etc., to facilitate subsequent processing, reduce accumulation, improve effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

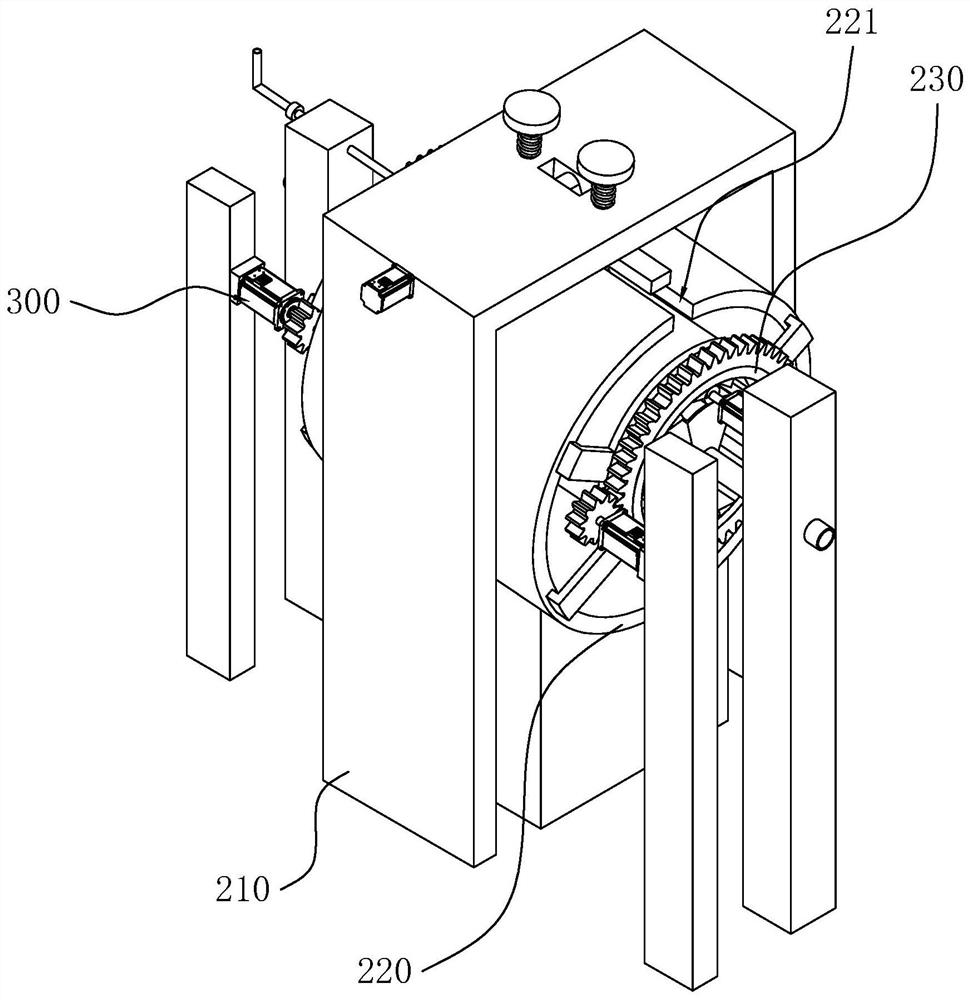

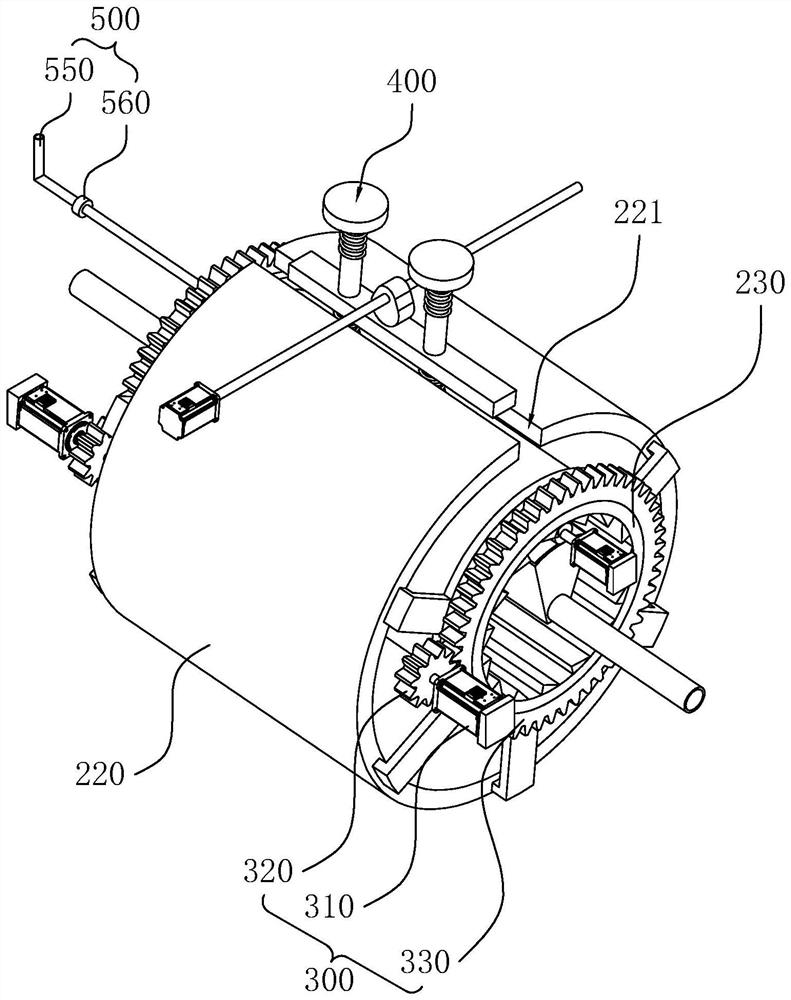

[0044] The following is attached Figure 1-5 The present invention is described in further detail.

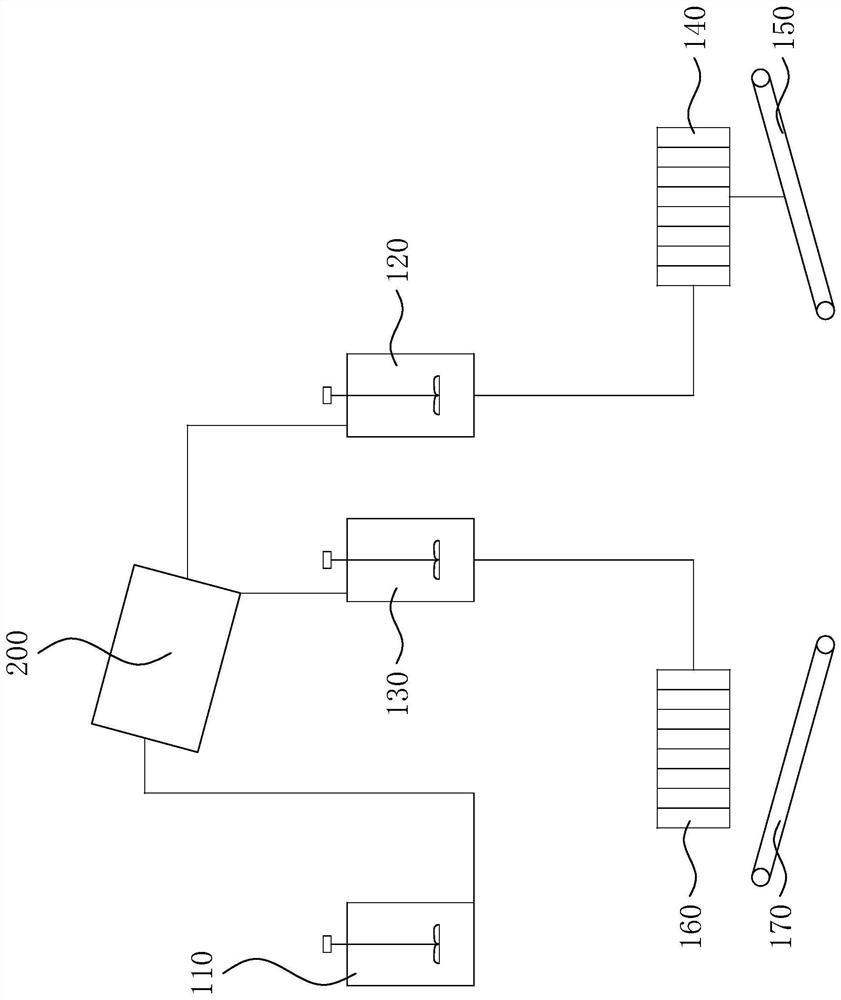

[0045] First, the embodiment of the present application discloses a waste catalyst wet recovery system. refer to figure 1 , The waste catalyst wet recovery system includes a raw material slurry storage tank 110 for storing raw material slurry, a wet magnetic separator 200 for separating magnetic materials and non-magnetic materials, and a magnetic slurry storage tank 120 for storing magnetic slurry , a nonmagnetic slurry storage tank 130 for storing nonmagnetic slurry, a first filter press 140 for separating out water in the magnetic slurry, and a second pressure filter for separating out water in the nonmagnetic slurry filter machine 160.

[0046] refer to figure 1 , the discharge end of the raw material slurry storage tank 110 is connected to the feeding end of the wet magnetic separator 200 through a slurry pump, and then the raw material slurry is pumped to the wet mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com