Method for repairing defects of aluminum and magnesium alloy castings

A technology for repairing casting defects and casting defects, which is applied in the field of defect treatment of aluminum and magnesium alloy castings, can solve problems such as unsatisfactory treatment effects, and achieve the effect of ensuring internal quality and mechanical properties, uniform internal quality, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

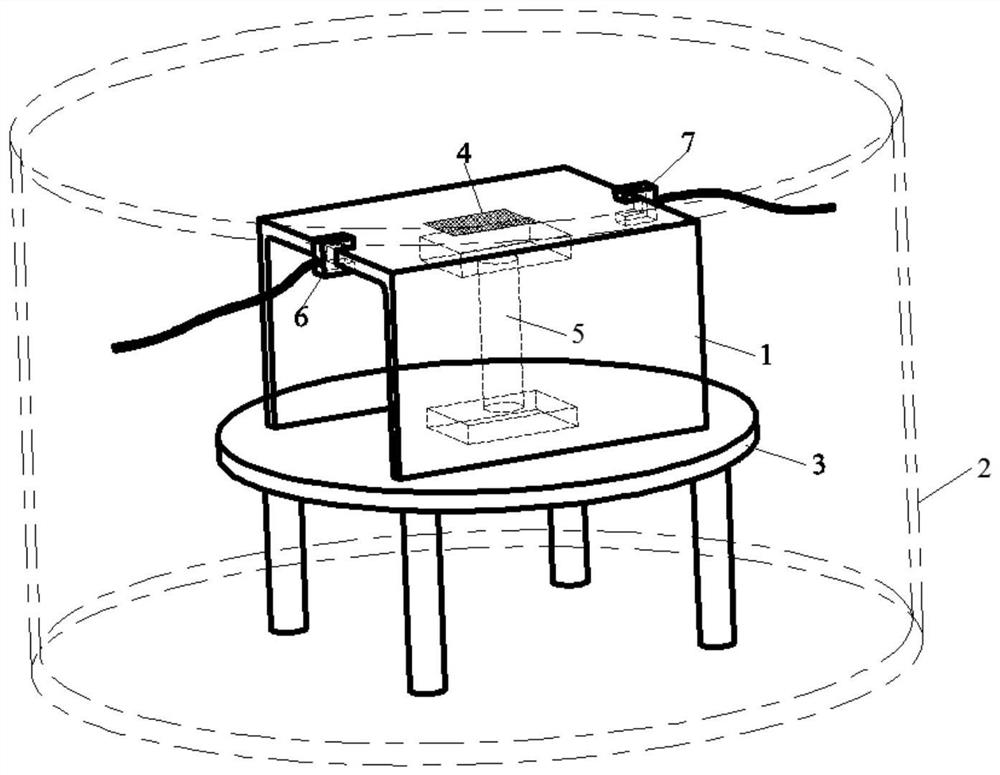

[0034] A method for repairing defects of aluminum and magnesium alloy castings of the present invention, the steps are as follows:

[0035] 1) Use X-rays to carry out non-destructive testing, identify the defect position of the casting, and mark the defect position;

[0036] 2) Grinding the outer surface corresponding to the defect position of the casting, and processing parallel grooves, so as to obtain the processed casting; the value range of the parallel groove width is 1-1.5mm, and the value range of the depth is 2-2.5mm, the parallel grooves are multi-row array structure, and the value range of the distance between two adjacent parallel grooves is 1.5-2mm. The area of the parallel grooves is larger than the defect area.

[0037] 3) Place the processed castings in an airtight container, extract the air in the airtight container to vacuum, and keep it for a certain period of time;

[0038] 4) Conducting electrification treatment on the casting until the defect position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com