Device and method for treating organic wastewater by using three-dimensional fluidized bed electrochemical system

A three-dimensional fluidized bed, organic wastewater technology, applied in chemical instruments and methods, oxidized water/sewage treatment, separation methods, etc., can solve the problems of iron-containing sludge difficult to handle, secondary pollution, etc., and achieve high-efficiency purification of organic wastewater. , to achieve the effect of recycling and increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

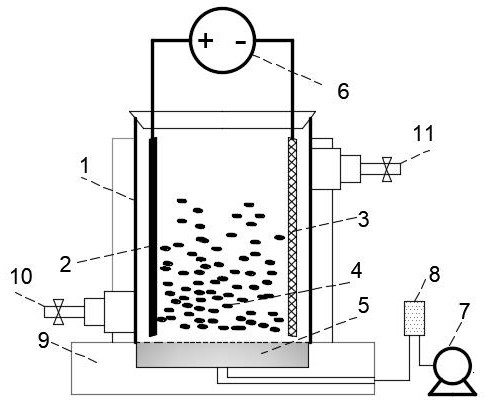

Method used

Image

Examples

Embodiment 1

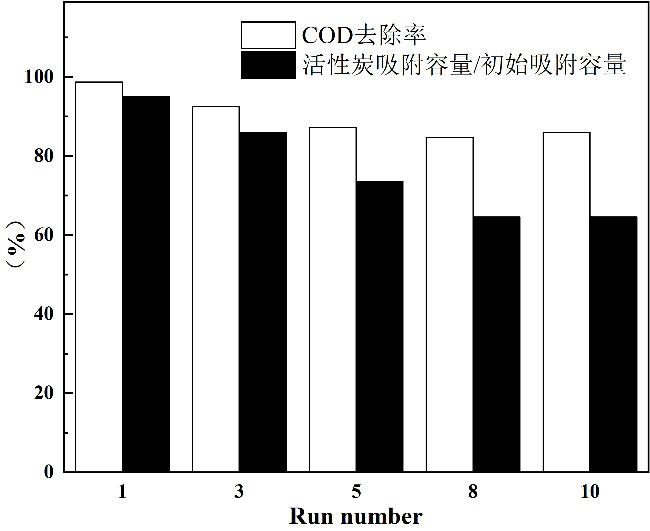

[0025] Three-dimensional electrochemical experiment: Add 120mL of 200mg / L methyl orange wastewater (COD value 1508mg / L) and 2.4g of activated carbon particles into the above reactor from the right inlet; adjust the temperature of the reactor through the temperature control device to 25°C; the air flow rate is adjusted to 1.0L / min; the voltage is adjusted to 15V; every 5min is sampled and measured, and the water quality COD value after 30min treatment is 19mg / L, the COD removal rate is 98.7%, and the COD removal rate constant k 1 is 0.197.

[0026] Two-dimensional electrochemical experiment: Add 120mL of 200mg / L methyl orange wastewater (COD value 1508mg / L) into the above reactor from the right inlet; adjust the temperature of the reactor to 25°C through the temperature control device; The air flow rate is adjusted to 1.0L / min; the voltage is adjusted to 15V; every 5min is sampled and measured, and the water quality COD value after 30min treatment is 538mg / L, the COD removal ra...

Embodiment 2

[0030] Add 120mL of 200mg / L methyl orange wastewater (COD value 1508mg / L) and 2.4g of activated carbon particles into the above reactor from the right inlet; adjust the temperature of the reactor to 25°C through the temperature control device; air The flow rate was adjusted to 1.0L / min; the voltage was adjusted to 5V; after 30 minutes of reaction, the COD value of the treated water was determined to be 276mg / L, and the COD removal rate was 81.6%.

Embodiment 3

[0032] Add 120mL of 200mg / L methyl orange wastewater (COD value 1508mg / L) and 1.2g of activated carbon particles into the above reactor from the right inlet; adjust the temperature of the reactor to 25°C through the temperature control device; air The flow rate was adjusted to 1.0L / min; the voltage was adjusted to 15V; after 30 minutes of reaction, the COD value of the treated water was determined to be 72mg / L, and the COD removal rate was 95.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com