Preparation process and equipment of nano carbon enzyme

A preparation process and nano-carbon technology, applied in the application, organic fertilizer, inorganic fertilizer and other directions, can solve the problems of easy deliquescence and reduced carbon enzyme activity, and achieve the effects of not easy to deteriorate, improve activity, and improve utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

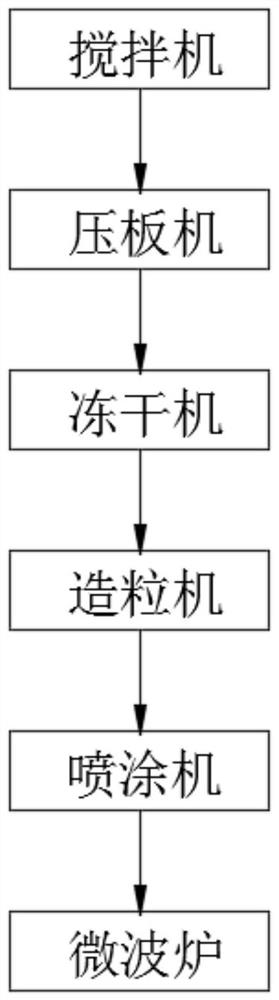

Method used

Image

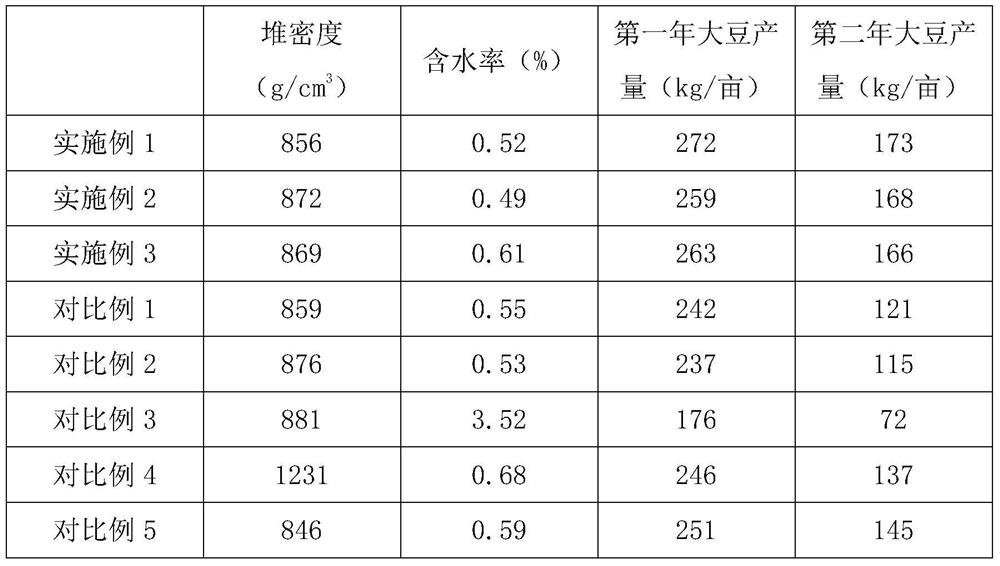

Examples

Embodiment 1

[0029] In embodiment 1, the preparation technology of nano carbon enzyme, comprises the following steps:

[0030] S1. Weighing raw materials: Weigh the following raw materials by weight: 8 parts of carbonase, 22 parts of plant ash, 15 parts of bentonite, 20 parts of water, 10 parts of nitrogen fertilizer, 9 parts of phosphate fertilizer, 18 parts of potassium fertilizer, 0.5 parts of high molecular weight chitosan 2 parts, 2 parts of polyferric sulfate, 3 parts of honey, 8 parts of vegetable oil;

[0031] S2, mixing and stirring: put carbonase, plant ash, bentonite, polymer chitosan, polyferric sulfate, water, nitrogen fertilizer, phosphate fertilizer and potassium fertilizer into the mixer, and mix evenly;

[0032] S3, freeze-drying treatment: use a plate press to press the uniformly mixed material into a plate shape, the working pressure of the plate press is 3MPa, and the holding time is 4h, and then use a freeze dryer to freeze-dry the plate-shaped material;

[0033] S4, ...

Embodiment 2

[0043] In embodiment 2, the preparation technology of nano carbon enzyme comprises the following steps:

[0044] S1. Weighing raw materials: Weigh the following raw materials by weight: 12 parts of carbonase, 35 parts of plant ash, 22 parts of bentonite, 30 parts of water, 18 parts of nitrogen fertilizer, 15 parts of phosphate fertilizer, 25 parts of potassium fertilizer, and 2 parts of polymer chitosan 4 parts, 4 parts of polyferric sulfate, 6 parts of honey, 12 parts of vegetable oil;

[0045] S2, mixing and stirring: put carbonase, plant ash, bentonite, polymer chitosan, polyferric sulfate, water, nitrogen fertilizer, phosphate fertilizer and potassium fertilizer into the mixer, and mix evenly;

[0046] S3, freeze-drying treatment: use a plate press to press the uniformly mixed material into a plate shape, the working pressure of the plate press is 5MPa, and the pressure holding time is 8h, and then use a freeze dryer to freeze-dry the plate-shaped material;

[0047] S4, g...

Embodiment 3

[0057] In embodiment 3, the preparation technology of nano carbon enzyme, comprises the following steps:

[0058] S1. Weighing raw materials: Weigh the following raw materials by weight: 10 parts of carbonase, 28 parts of plant ash, 19 parts of bentonite, 25 parts of water, 14 parts of nitrogen fertilizer, 12 parts of phosphate fertilizer, 22 parts of potassium fertilizer, 1 part of high molecular weight chitosan 3 parts, 3 parts of polyferric sulfate, 4 parts of honey, 10 parts of vegetable oil;

[0059] S2, mixing and stirring: put carbonase, plant ash, bentonite, polymer chitosan, polyferric sulfate, water, nitrogen fertilizer, phosphate fertilizer and potassium fertilizer into the mixer, and mix evenly;

[0060] S3, freeze-drying treatment: use a plate press to press the uniformly mixed material into a plate shape, the working pressure of the plate press is 4MPa, and the pressure holding time is 6h, and then use a freeze dryer to freeze-dry the plate-shaped material;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com