Online automatic detection method for nitrogen content in steel

A technology of automatic detection and nitrogen content, which is applied in the field of online automatic detection of nitrogen content in steel and analysis of steel composition, and can solve problems such as detection accuracy not up to standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

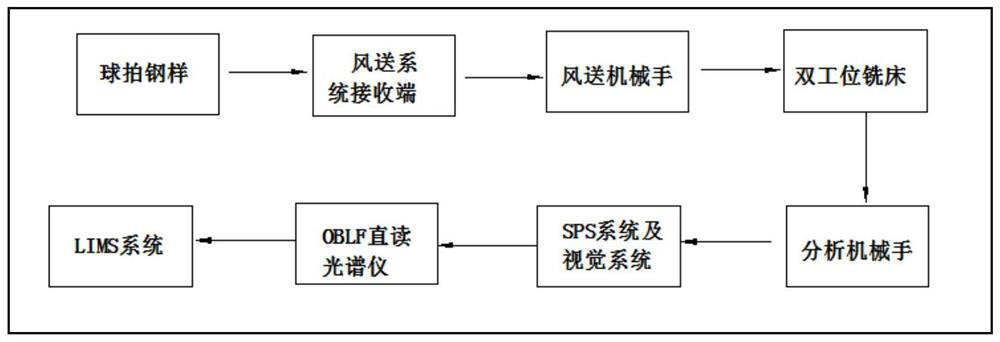

[0072] Provided is an on-line automatic detection method for nitrogen content in steel, comprising the following steps: (1) setting and using technical parameters. The time for the air-delivered sample receiving manipulator to accept the description and put the steel sample into the vise position of the double-station milling machine is 4.5s. The sample depth is 0.7mm, the time for the spectroscopic analysis manipulator to send the racket steel sample to the excitation platen of the direct-reading spectrometer is 10s, and the technical parameters of the direct-reading spectrometer include rinsing time 3s, pre-burning time 1s, exposure time 5s, etc. , the flow of argon is 710L / h, the pressure of argon in the pipeline is 0.8MPa, 0.84MPa, 0.88MPa, 0.90MPa, and it is decompressed to 0.40MPa, 0.42MPa, 0.44MPa, 0.45MPa before being transported to the spectrometer.

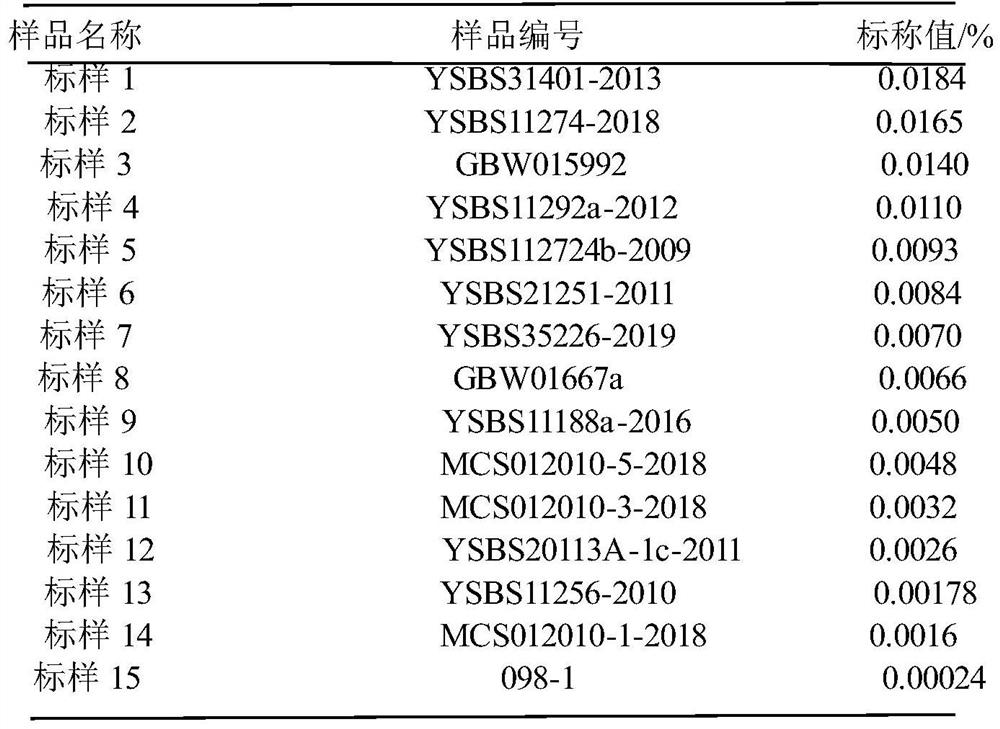

[0073] (2) Draw the working curve. The national standard material and the industry standard material were selected as...

Embodiment 2

[0081] According to the automatic detection method of nitrogen content in Example 1, the argon gas pressure in the pipeline is 0.55, 0.58, 0.60, 0.62, 0.65, 0.68, 0.69, 0.71, 0.74Mpa, and it is decompressed twice to 0.36, 0.38, 0.39 before being transported to the spectrometer. , 0.40, 0.42, 0.44, 0.45, 0.46, 0.48Mpa.

[0082] The argon pressure in the pipeline is 0.72, 0.76, 0.78, 0.92, 0.96Mpa, and the pressure is reduced to 0.36, 0.38, 0.39, 0.46, 0.48Mpa for the second time before being transported to the spectrometer.

[0083] The method of Example 1 and Example 2 was used to determine the nitrogen content of the Q345 steel production samples. The specific results are shown in Table 2.

[0084] Table 2 Different argon pressure values of the direct-reading spectrometer and the ratio of the pressure of the direct-reading spectrometer to the argon pressure of the pipeline, the nitrogen content value of Q345 steel was determined

[0085]

[0086]

[0087] It can be see...

Embodiment 3

[0089] According to the automatic detection method of nitrogen content in Example 1, measure the nitrogen content of the standard samples YSBS11188a-2016 and IMZ110A, the pressure of the direct-reading spectrometer is 0.42MPa, and the ratio of the pressure of the direct-reading spectrometer to the argon pressure in the pipeline is selected as 0.30, 0.35, and 0.40. , 0.45, 0.50, 0.55, 0.60, 0.65, 0.70, the specific results are shown in Table 3 and Table 4.

[0090] Table 3 The ratio of the pressure of the direct reading spectrometer to the argon gas pressure in the pipeline to measure the nitrogen content of the YSBS11188a-2016 standard sample

[0091]

[0092] Table 4 Determination of nitrogen content of IMZ110A standard sample by the ratio of different direct reading spectrometer pressure and pipeline argon pressure

[0093]

[0094] From Table 3 and Table 4, the ratio of the pressure into the direct reading spectrometer to the argon pressure in the pipeline is 0.4 to 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com