Ramie fiber grafted cyclobalanopsis glauca tannin material and preparation method thereof

A technology for grafting green oak and ramie fibers, which is applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of high material cost, cannot be recycled repeatedly, poor acid and alkali resistance, etc., and achieves a high grafting rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention discloses a preparation method of ramie fiber grafted Quercus qinggang tannin material, which comprises the following steps:

[0030] Step 1, preparation of tannin solution: naturally air-dry the bark of Quercus qinggang, crush it, and pass it through a 100-mesh sieve for use; take the bark powder of Quercus qinggang, and add acetone and water with a volume ratio of 1:1 into the bark of Quercus qinggang , wherein the mass ratio of Quercus qinggang bark to water was 1:20, and was shaken with a constant temperature oscillator for 24 hours at a temperature of 30°C, then suction filtered and the filtrate was adjusted to 1000mL to prepare a tannin solution.

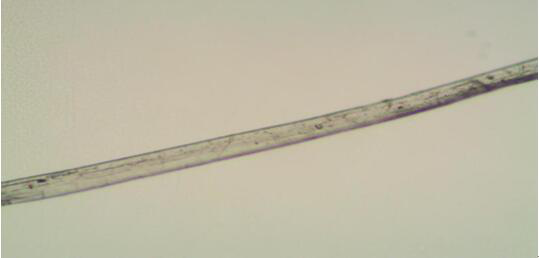

[0031] Step 2, carry out pretreatment to ramie fiber: use 0.5mol / LHNO to ramie fiber 3 The solution was soaked for 2 hours, wherein the mass ratio of ramie fiber to Quercus qinggang bark powder was 1:25. After the soaking time, the ramie fiber was washed with deionized water to neutrality by using a suctio...

Embodiment 1

[0038] A kind of preparation method of ramie fiber grafting Quercus alba tannin material, comprises the following steps:

[0039] Step 1. Preparation of tannin solution: Air-dry the bark of Quercus qinggang naturally, crush it, and pass it through a 100-mesh sieve for use; accurately weigh 25g of bark powder and put it into it, then measure 500mL of acetone water with a ratio of 1:1 and pour it into In the Erlenmeyer flask, vibrate with a constant temperature oscillator for 24 hours at a temperature of 30°C, then filter with suction and adjust the volume of the filtrate to 1000mL to prepare a tannin solution;

[0040]Step 2, carry out pretreatment to ramie fiber: accurately weigh 1 g of ramie fiber, use 0.5mol / LHNO 3 Soak the solution for 2 hours. After the soaking time, use a suction filter to filter and rinse the ramie fiber with deionized water to neutrality, then soak it with 0.5 mol / L NaOH solution for 2 hours, and use a suction filter to filter it with deionized water. ...

Embodiment 2

[0046] A kind of preparation method of ramie fiber grafting Quercus alba tannin material, comprises the following steps:

[0047] Step 1. Preparation of tannin solution: Air-dry the bark of Quercus qinggang naturally, crush it, and pass it through a 100-mesh sieve for use; accurately weigh 25g of bark powder and put it into it, then measure 500mL of acetone water with a ratio of 1:1 and pour it into In the Erlenmeyer flask, vibrate with a constant temperature oscillator for 24 hours at a temperature of 30°C, then filter with suction and adjust the volume of the filtrate to 1000mL to prepare a tannin solution;

[0048] Step 2, carry out pretreatment to ramie fiber: accurately weigh 1 g of ramie fiber, use 0.5mol / LHNO 3 Soak the solution for 2 hours. After the soaking time, use a suction filter to filter and rinse the ramie fiber with deionized water to neutrality, then soak it with 0.5 mol / L NaOH solution for 2 hours, and use a suction filter to filter it with deionized water. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com