Biogas slurry fertilizer and preparation method thereof

A biogas slurry and fertilizer technology, applied in the agricultural field, can solve the problems of lack of effective means to inhibit pathogenic bacteria, ammonium ions in biogas slurry decomposition, and reduced fertilizer effect of biogas slurry, so as to improve crop quality, improve fertilizer effect, and shorten fermentation time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] One embodiment of the present invention proposes a method for preparing biogas slurry fertilizer, comprising the following steps:

[0033] (1) Mix biogas slurry with agricultural enzymes and ferment to obtain a mixture;

[0034] (2) adding water to the mixture obtained in step (1) to prepare biogas slurry fertilizer.

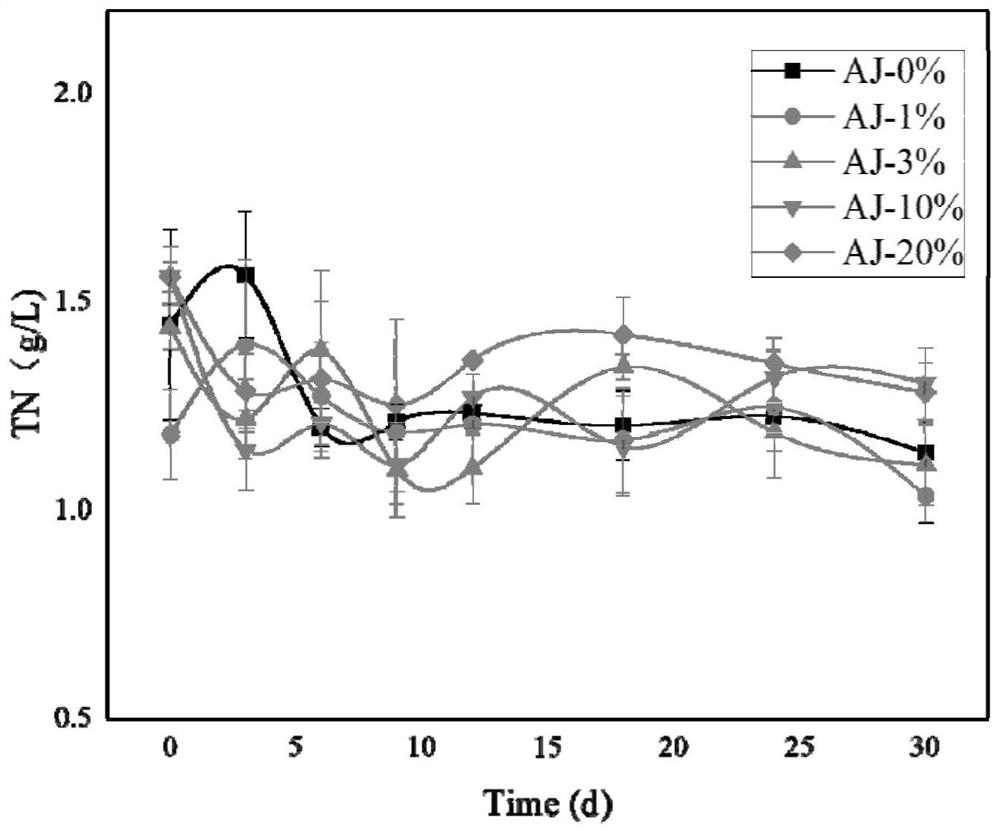

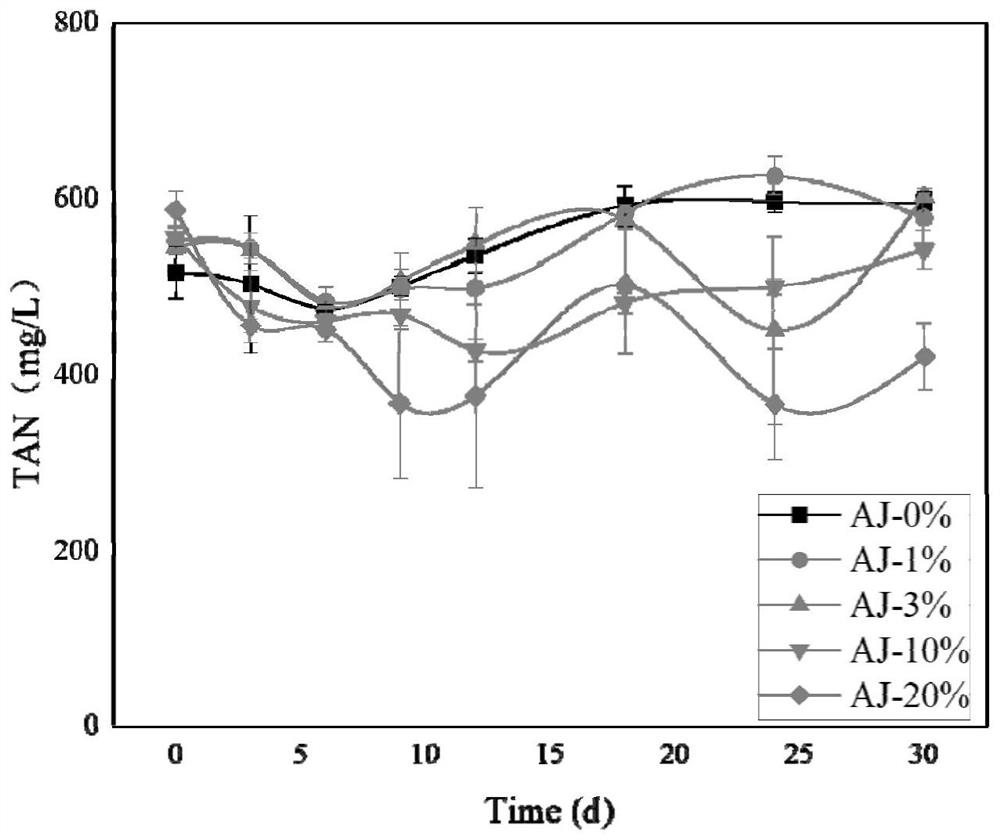

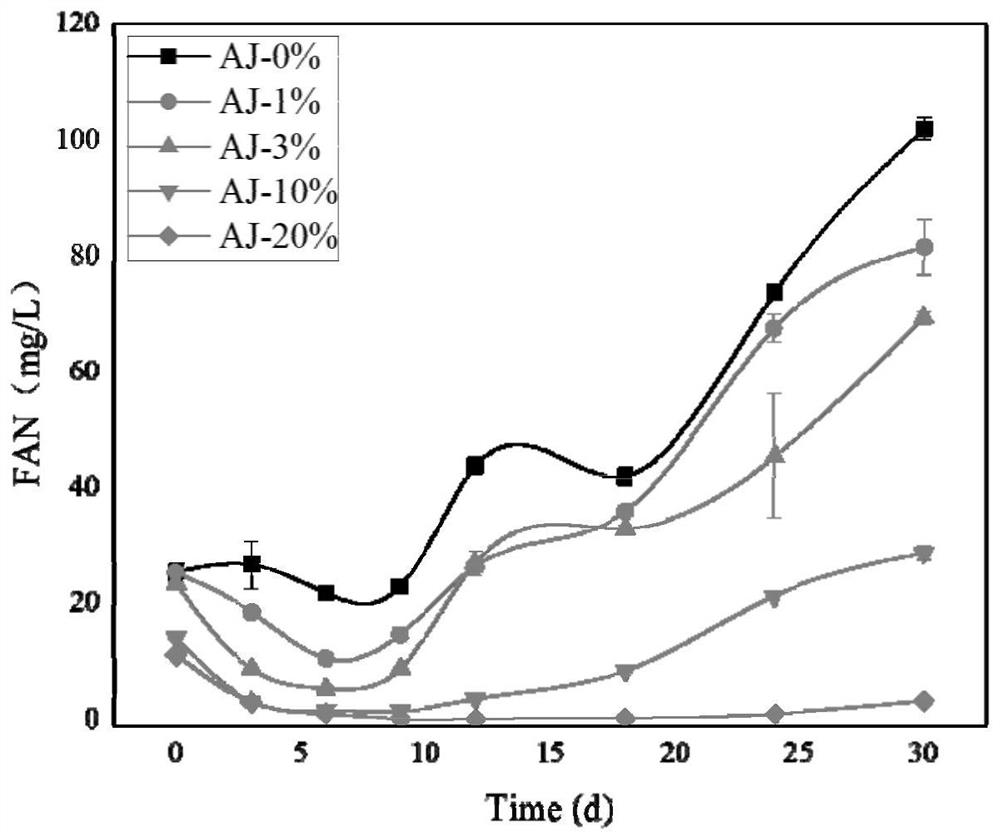

[0035] In the embodiment of the present invention, the agricultural enzyme and the biogas slurry work together to adjust the pH, shorten the fermentation time, accelerate the decomposition of organic matter, reduce the concentration of total ammonia nitrogen and free ammonia, and help reduce the inhibition of plant growth by ammonia in the biogas slurry, and reduce The emission of irritating gas during storage. In addition, the synergistic effect of agricultural enzymes and biogas slurry can realize the effective conversion of ammonia, reduce the total ammonia nitrogen content in fermentation, and help to preserve nitrogen, promote nitrification, and redu...

Embodiment 1

[0055] Embodiment 1: a kind of preparation method of biogas slurry fertilizer

[0056] (1) Mix agricultural enzymes and biogas slurry at a volume ratio of 1:5 to prepare a mixture. in,

[0057] Agricultural enzymes are obtained by mixing brown sugar, fruit and vegetable waste, and water in a mass ratio of 1:3:10, and fermenting at a constant temperature of 30°C for 90 days;

[0058] Biogas slurry is obtained by mixing human excrement: kitchen waste: turfgrass at a total solid ratio of 0.335:1:1.335, with a hydraulic retention time (HRT) of 30 days, and anaerobic fermentation at 35°C.

[0059] (2) Put the mixture obtained in step (1) in a light-proof container, seal it with a plastic film, and ferment at 25° C. for 30 days to obtain a fermentation product.

[0060] (3) Mix the fermentation product obtained in step (2) with clear water at a volume ratio of 1:1 to prepare biogas slurry fertilizer.

Embodiment 2

[0061] Example 2 : With embodiment 1, difference is that in step (1), agricultural ferment and biogas slurry are mixed by volume ratio of 1:10, and the volume difference with embodiment 1 is eliminated by adding water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com