A self-limiting temperature conductive ink, preparation method and heating ceramics

A conductive ink, self-limiting temperature technology, applied in the direction of ink, electric heating device, ohmic resistance heating, etc., can solve the problems of inability to achieve overall temperature control, heating power attenuation, etc., to prevent circuit damage and heat attenuation, and maintain long-term Use, effects from a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

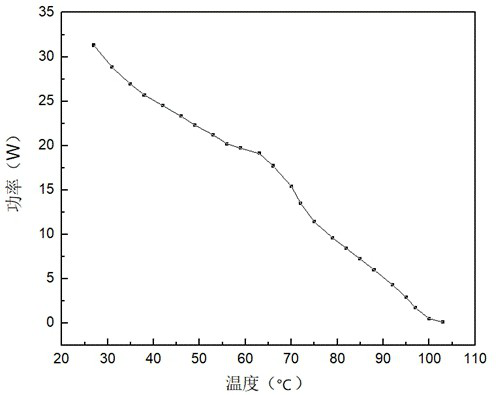

Image

Examples

preparation example Construction

[0040] A preparation method of self-limiting temperature conductive ink, comprising the steps of:

[0041] S1. According to the mass percentage of carbon-based conductive filling material 18% ~ 45%, self-limiting temperature material 6% ~ 10%, resin bonding material 20% ~ 48%, additive 3% ~ 6%, solvent 25% ~ 45% , mixing the carbon-based conductive filling material, self-temperature-limiting material, resin binder, additive and solvent, and then ball milling for more than 1 hour, making the mixture fully ground and dispersed until the particle size of the mixture is <10um, to obtain the self-limiting temperature conductive ink;

[0042] The carbon-based conductive filling material is at least one of graphene, nano-carbon powder and carbon nanotubes; the resin binder is a resin with a melting point greater than 320° C., and the particle size of the resin binder is 3-3 10 μm; the solvent is at least one of diethylene glycol butyl ether, diethylene glycol methyl ether, terpineol,...

Embodiment 1

[0052] A preparation method of self-limiting temperature conductive ink, comprising the steps of:

[0053] S1. According to mass percentage, carbon-based conductive filler material 27%, self-limiting temperature material 8%, resin adhesive 30%, additive 3% (1% dispersant, 2% leveling agent), solvent 32% (10% terpineol, 22% propylene glycol diacetate) are mixed and ball milled for more than 1 hour, and the mixture is fully ground and dispersed until the particle size of the mixture is <10um to obtain the self-limiting temperature conductive ink;

[0054] The carbon-based conductive filling material is 30% graphene, 30% nano-carbon powder and 40% carbon nanotubes;

[0055] The preparation process of the self-limiting temperature material comprises the following steps:

[0056] S11. By mass percentage, 56% BaTiO 3 , 32% SrTiO 3 , 6% Cr 2 o 3 , 4%La 2 o 3 , 0.7% CaCO 3 , 0.8% SiO 2 and 0.5% Al 2 o 3 After mixing, BaTiO3, SrTiO 3 、Cr 2 o 3 and La 2 o 3 The mass rati...

Embodiment 2

[0062] A preparation method of self-limiting temperature conductive ink, comprising the steps of:

[0063] S1. According to mass percentage, 24% of carbon-based conductive filling material, 7% of self-limiting temperature material, 24% of resin bonding material, 2% of additives (0.5% of dispersant, 1.5% of leveling agent), and 43% of solvent (8% isophorone, 35% diethylene glycol butyl ether) are mixed and ball milled for more than 1 hour, and the mixture is fully ground and dispersed until the particle size of the mixture is <10um, and the self-limiting temperature conductive ink is obtained;

[0064] The carbon-based conductive filling material is graphene and nano-carbon powder, and the mass ratio of graphene and nano-carbon powder is 1.5:1;

[0065] The preparation process of the self-limiting temperature material comprises the following steps:

[0066] S11. By mass percentage, 48% BaTiO 3 , 38% SrTiO 3 , 7% Cr 2 o 3 , 5%La2 o 3 , 0.7% CaCO 3 , 1%SiO2 2 and 0.3% Al ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com