Conductive ink with temperature-limiting properties, preparation method and heating tile

A kind of conductive ink and characteristic technology, applied in the direction of ink, electric heating device, ohmic resistance heating, etc., can solve the problem of short cycle life of heating tiles, and achieve the effect of stable self-limiting temperature effect, preventing circuit overheating, and high cycle life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A preparation method of conductive ink with temperature-limiting characteristics, comprising the steps of:

[0042] S1. According to the following mass percentages, 12%-40% of carbon-based conductive filling materials, 5%-8% of conductive auxiliary materials, 7%-13% of temperature-limiting materials, 10%-28% of resin bonding materials, and 9.5% of additives 14% and 28% to 50% of the solvent are mixed and ball milled for more than 30 minutes to make the grinding and dispersion to a particle size of <10um to obtain the conductive ink with a viscosity of 80 to 120pa·s with temperature-limiting characteristics;

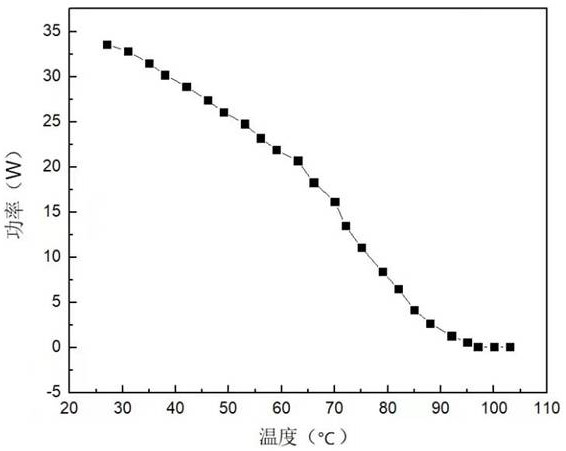

[0043] The conductive auxiliary material is nickel-chromium alloy powder, the temperature-limiting material is titanium diboride heat-sensitive conductive material, and the Curie temperature of the titanium diboride heat-sensitive conductive material is 60-80°C;

[0044] The conductive ink with temperature-limiting characteristics has a resistivity of 2.3-2.6Ω·mm a...

Embodiment 1

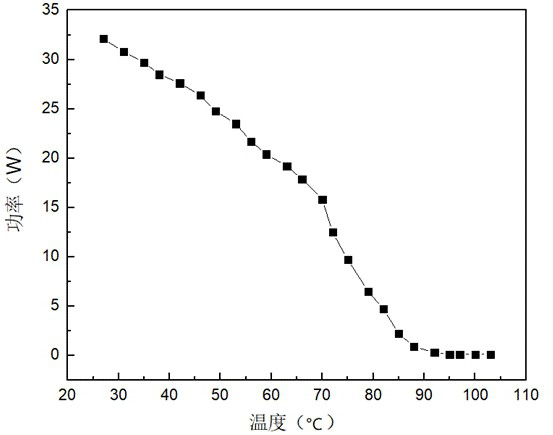

[0057] A preparation method of conductive ink with temperature-limiting characteristics, comprising the steps of:

[0058] S1. According to the following mass percentages, 15% of carbon-based conductive filler material, 6% of nickel-chromium alloy powder conductive auxiliary material, 10% of temperature-limiting material (titanium diboride heat-sensitive conductive material), 15% of resin adhesive material, isopropyl Tris(dioctylpyrophosphate acyloxy) titanate coupling agent 0.6%, stearic acid 1.5%, ammonium polyphosphate flame retardant 8.9%, propylene glycol diacetate 17% and isophorone 26% After mixing, ball mill for more than 30 minutes to make it grind and disperse to a particle size of <10um to obtain a conductive ink with temperature-limiting characteristics;

[0059] The particle size of the nickel-chromium alloy powder is 35 μm, the fluidity is 28s / 50g, and the bulk density is 6.5g / cm 3 ;

[0060] The carbon-based conductive filling material is prepared from raw mat...

Embodiment 2

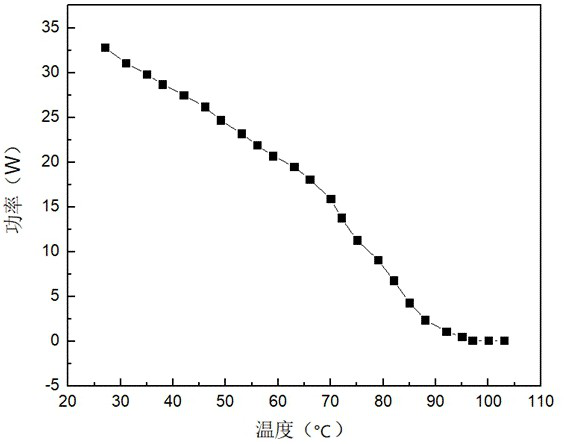

[0068] A preparation method of conductive ink with temperature-limiting characteristics, comprising the steps of:

[0069] S1. According to the following mass percentages, 18% of carbon-based conductive filler material, 7% of nickel-chromium alloy powder conductive auxiliary material, 11% of temperature-limiting material (titanium diboride heat-sensitive conductive material), 18% of resin adhesive material, isopropyl Tris(dioctyl pyrophosphate acyloxy) titanate coupling agent 1%, stearic acid 1%, ammonium polyphosphate flame retardant 8%, tripropylene dibutyl ether 36%, ball milled for more than 30min after mixing, Make it grind and disperse to a particle size of <10um to obtain a conductive ink with temperature-limiting characteristics;

[0070] The particle size of the nickel-chromium alloy powder is 40 μm, the fluidity is 23s / 50g, and the bulk density is 5g / cm3;

[0071] The carbon-based conductive filling material is prepared from raw materials with the following mass per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com